Corduroy fabric

A corduroy and fabric technology, applied in knitting, weft knitting, warp knitting, etc., can solve the problems of easy shedding of fluff, hair loss, and low production efficiency, and achieve the effect of high speed and increased production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] First of all, because the corduroy fabric of the present invention is produced by knitting on a circular knitting machine, and the knitting working principle and technology of the circular knitting machine have been clearly understood by those familiar with the technology, it is not the purpose of the application of the present invention, so No more descriptions are needed to explain the knitting working principle and technology of the circular knitting machine mentioned below, which is hereby explained.

[0025] The preferred embodiment and technical contents of the corduroy fabric of the present invention are described as follows in conjunction with the accompanying drawings:

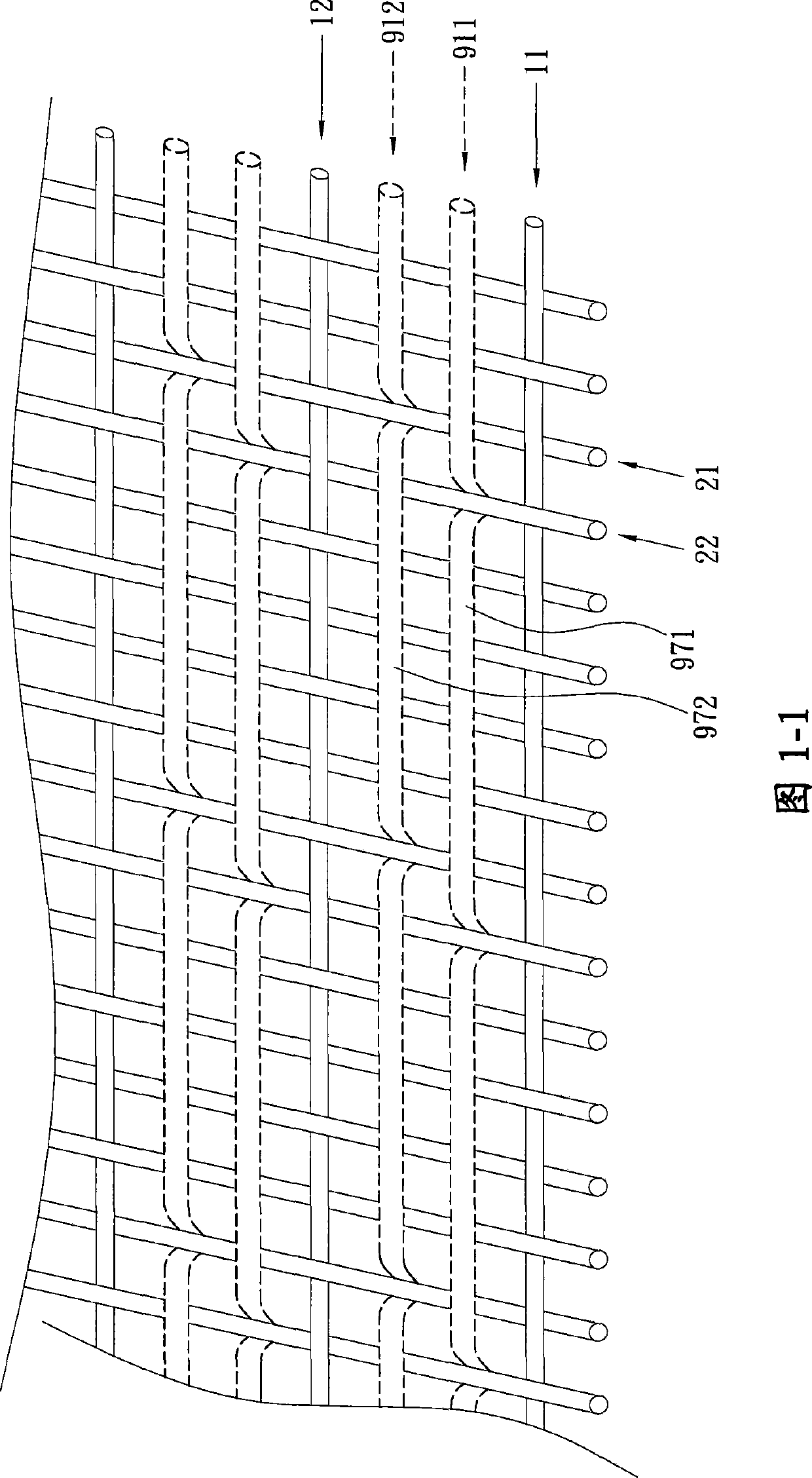

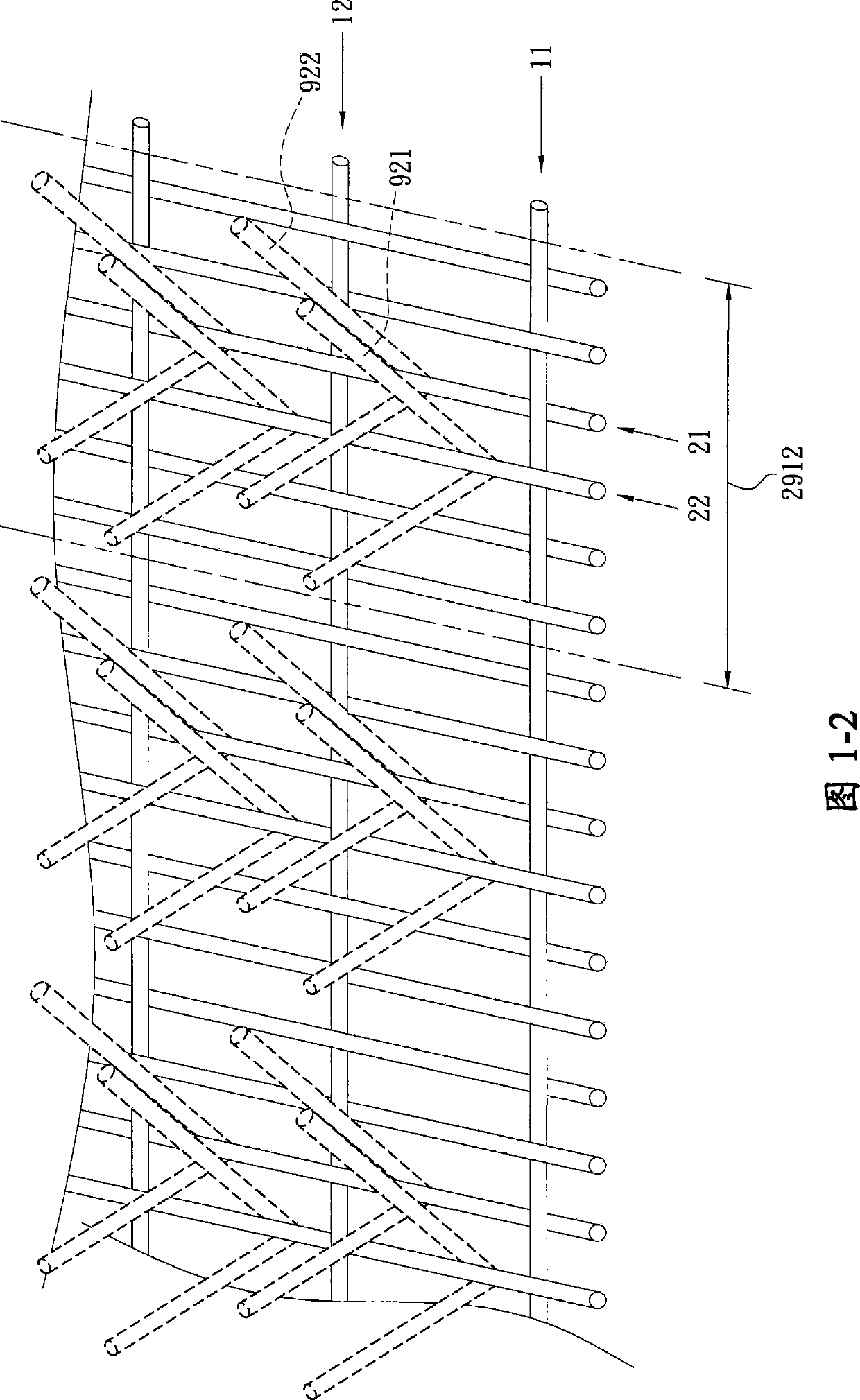

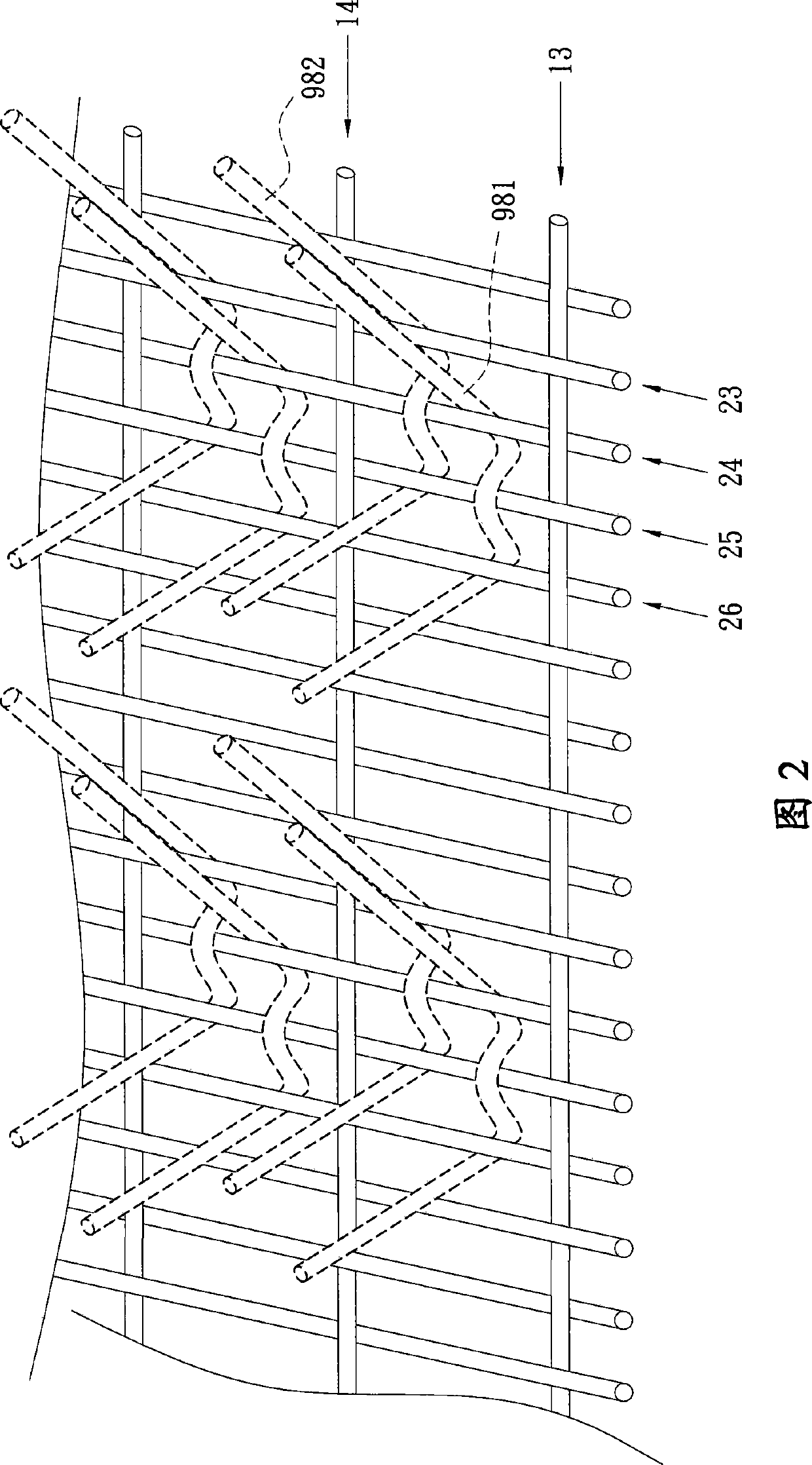

[0026] Please refer to Fig. 3-1 and Fig. 3-2 at the same time, which are a partial schematic diagram and a partial enlarged schematic diagram of the first type of weave of the corduroy fabric of the present invention. Among the figure, only the weave label formed by two groups of transverse wef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com