Method for making 180 degree big span second grade optical axis parallelism angle mirror

A technology with parallel optical axes and manufacturing methods, applied in optics, optical components, manufacturing tools, etc., can solve problems such as difficult practical operation, difficult control, and inability to heat angle mirrors, etc., to achieve strong practicability and popularization, and ensure parallelism The effect of improving precision and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

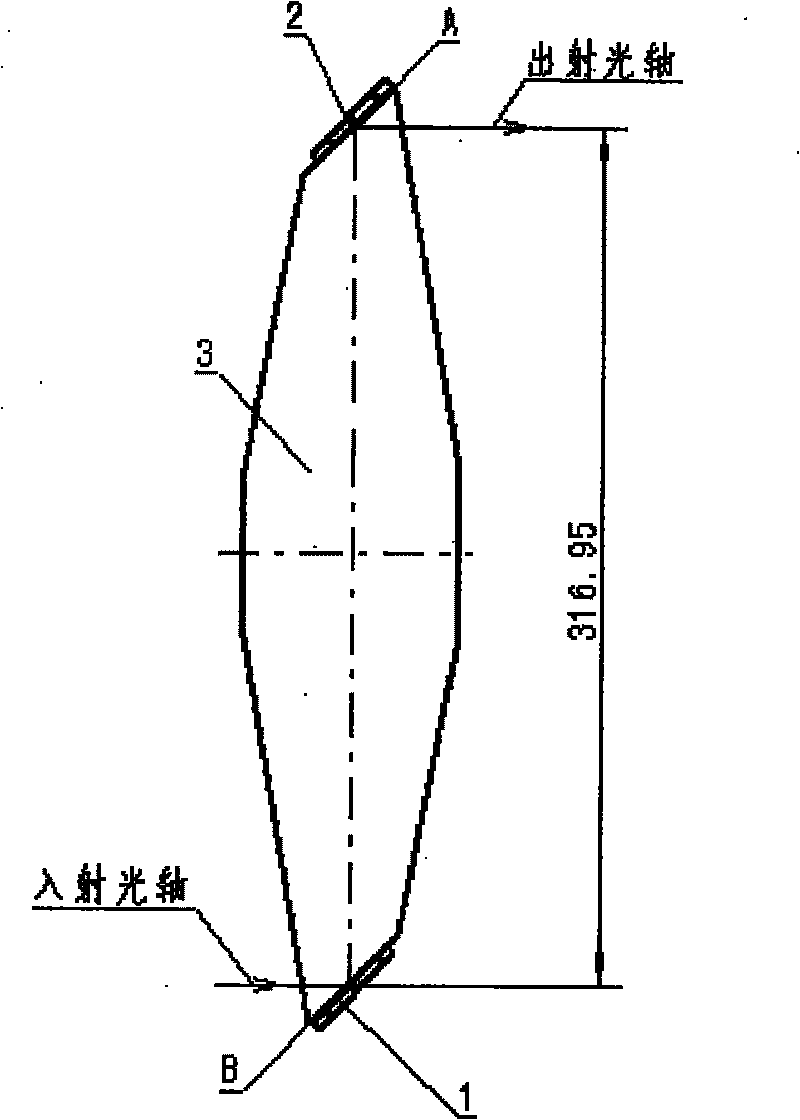

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0028] The manufacturing method of the cube corner lens in the preferred embodiment of the present invention includes the following processing and inspection steps.

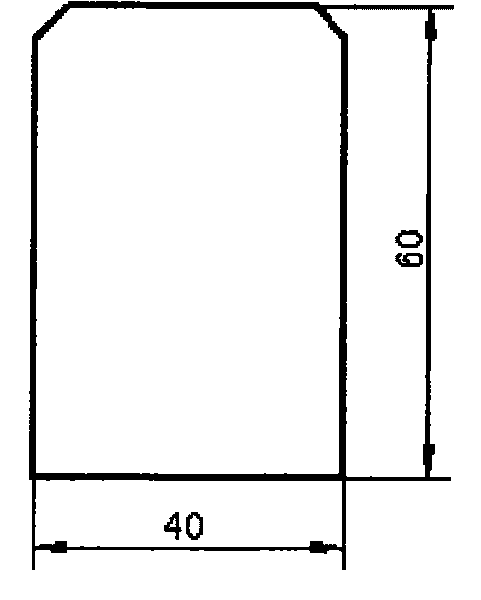

[0029] In the first step, the first and second flat mirrors 1 and 2 are processed by conventional optical parts processing technology according to the drawing requirements. The materials of the first and the second plane reflectors 1 and 2 are quartz glass, the reflective surface size is 40mm * 60mm, and the thickness is 20mm (see figure 2 ). The surface accuracy index is: N≤0.5ΔN≤0.2B≤III.

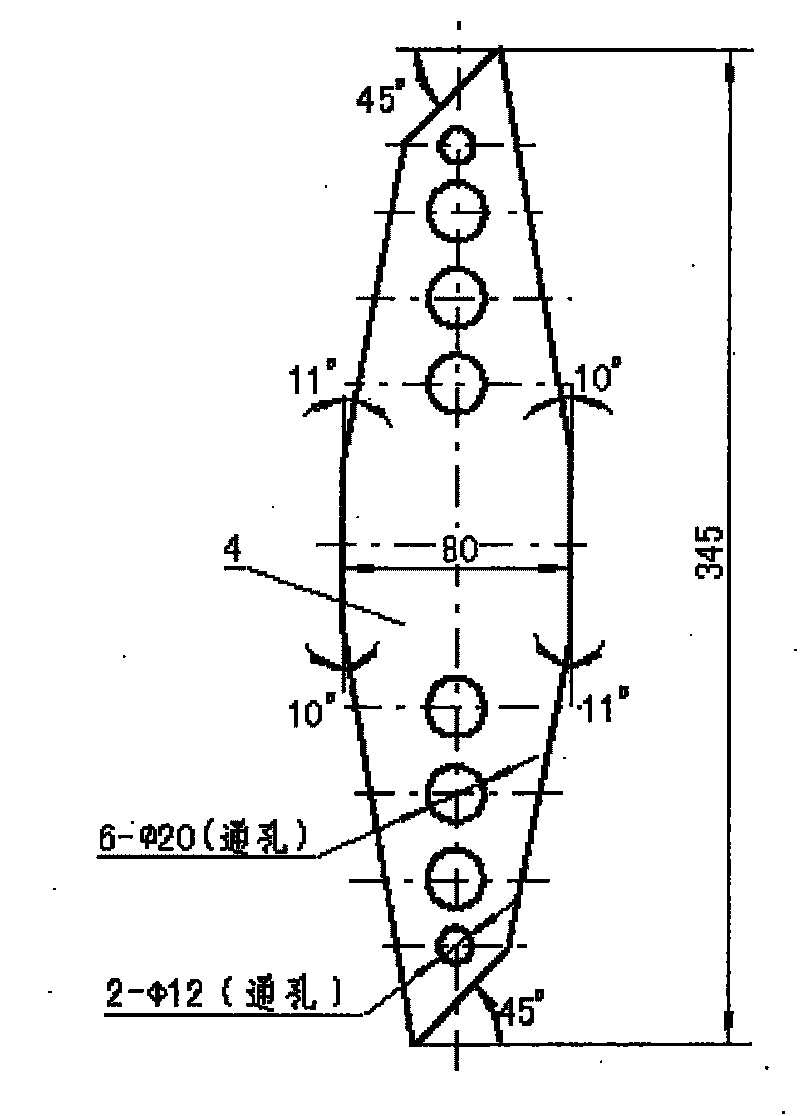

[0030] In the second step, the rectangular blank of the supporting plate 3 is formed after the quartz glass is blanked according to the conventional flow, the base is flat, and ground, and two identical rectangular blanks and the aluminum template 4 (referring to image 3 ) on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com