Automatic detection apparatus for thin camber

An automatic detection device and camber technology, applied in the direction of mechanical counter/curvature measurement, etc., can solve the problems that it is difficult to meet the needs of a large number of measurements, it is difficult to ensure measurement accuracy, and the measurement error is large, so as to reduce the occurrence of unqualified products The efficiency, measurement results are intuitive and easy to see, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

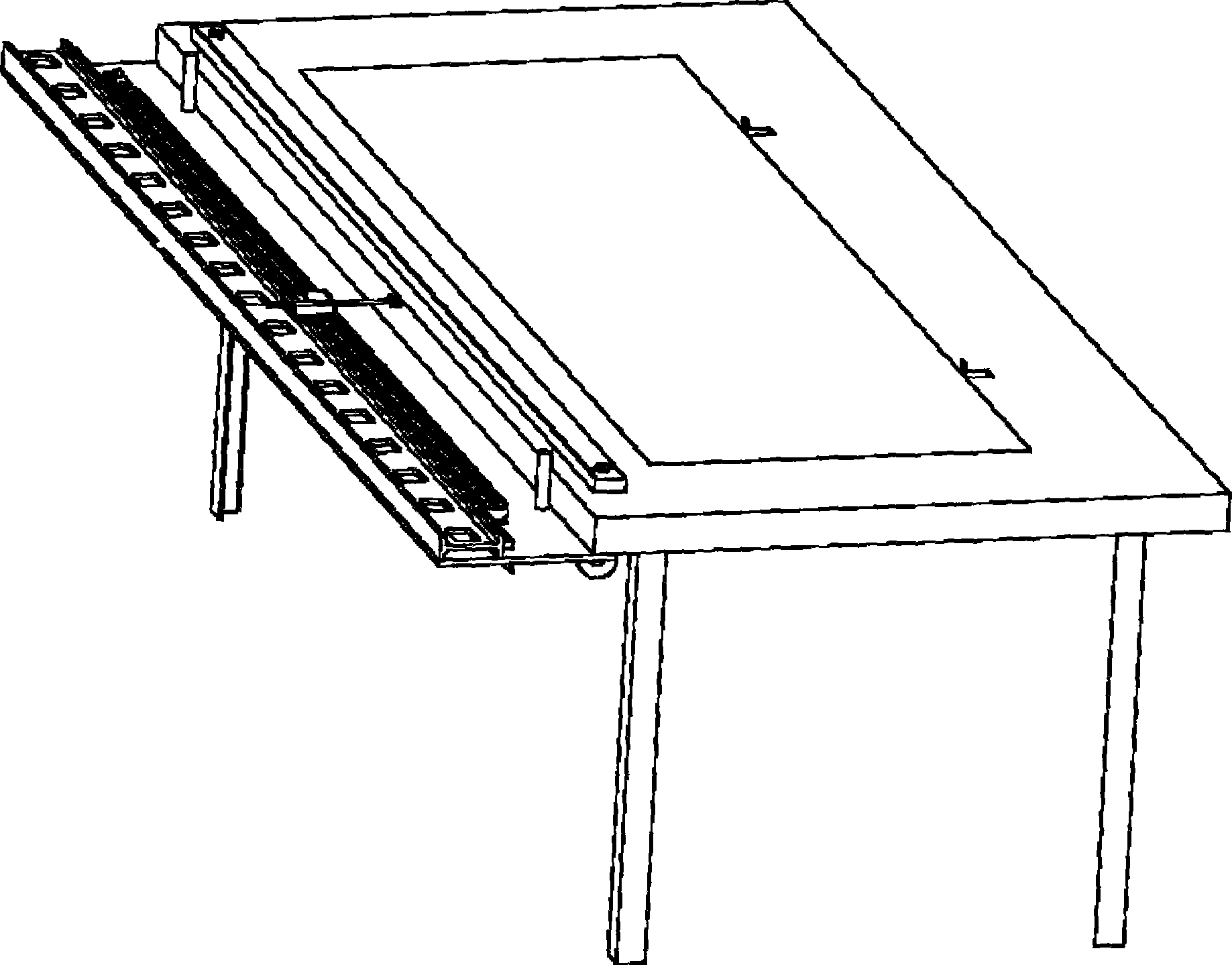

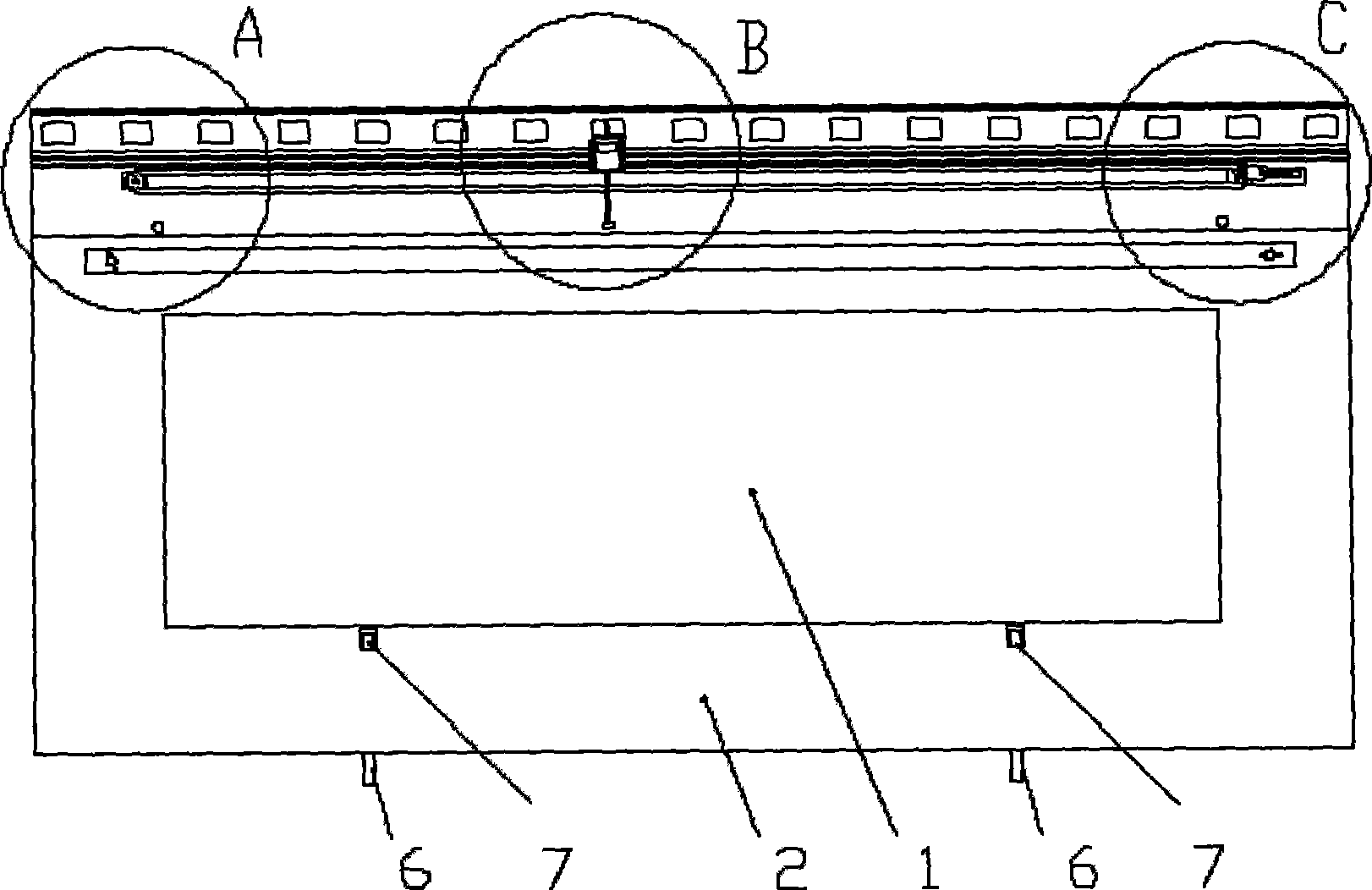

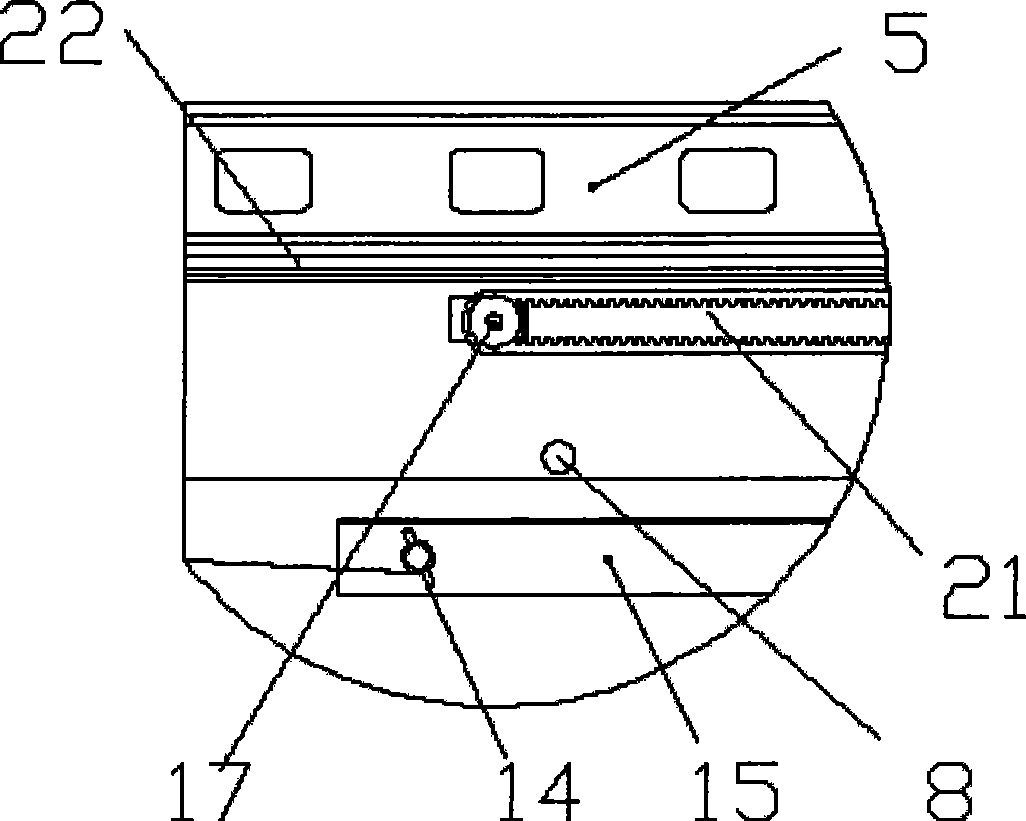

[0036] The thin plate camber automatic detection device of the present invention is mainly used for measuring the camber of thinner plates. For steel coils, it is necessary to take a specified length sample on the shearing unit for measurement. Its applicable measurement range is: plates with a width between 100mm and 1500mm and a thickness between 0.10mm and 1.00mm.

[0037] The main structure of the present invention is a rectangular measuring platform 2, and the measuring platform 2 is used for installing and fixing various measuring instruments and fixing the steel plate 1 to be tested. The main curvature measuring device is installed on the edge of one side of the measuring table 2, and we set this side as the measuring side.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com