Horizontal nib-hidden type long and short nose rail splitting method

A hidden point and horizontal technology, applied in the direction of track, road, building, etc., can solve the problems of unfitness, weak structure, and large stress on the connecting bolts of long and short core rails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

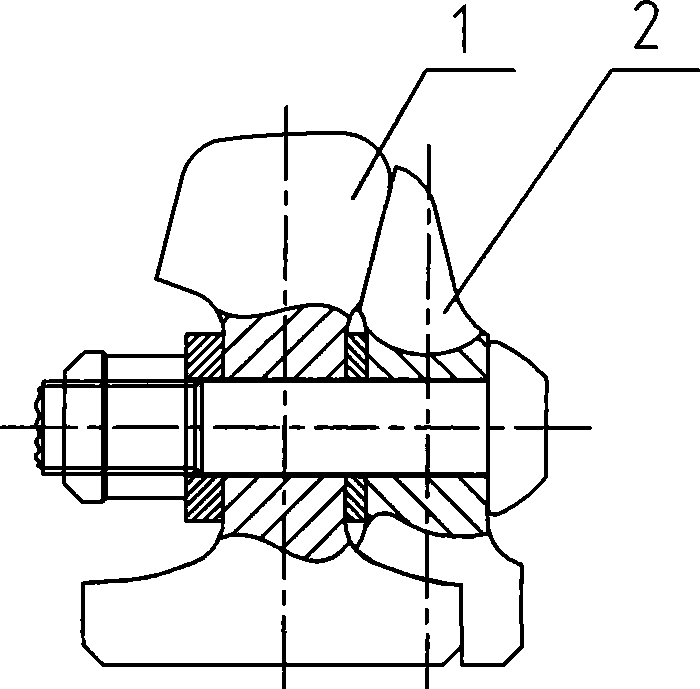

[0011] Embodiment 1: with reference to attached figure 1 . The splicing method of the long and short core rails of the horizontal hidden tip type, the long core rail 1 and the short core rail 2 are connected by bolts, and the long core rail 1 is closely attached to the short core rail 2, according to the inner 1:4 oblique Horizontal cutting of 4mm, long core rail 1 is within the range of close contact with short core rail 2, and the working edge of long core rail 1 is chamfered at 45°; , close to the long core rail 1, and the tip of the short core rail 2 is about 4mm wide. The difference between the processing technology of the long center rail 1 and the existing technology is that the working edge of the close-fitting section rail head is chamfered at 45°, and the existing technology and equipment can meet the processing requirements. The processing technology of the short center rail is basically the same as that of the existing turnout short center rail, and the existing...

Embodiment 2

[0012] Embodiment 2: On the basis of Embodiment 1, the splicing method of the long and short core rails of the horizontal hidden tip type, the long core rail 1 and the short core rail 2 are connected by bolts, and the long core rail 1 is connected with the short core rail 2 For the close-fitting position, cut 2mm horizontally according to the inner 1:3 slope, the long core rail 1 is within the range of close contact with the short core rail 2, and the working edge of the long core rail 1 is chamfered at 45°; the short core rail The edge of rail 2 is close to the outer 1:3 oblique, which is closely attached to the long core rail 1; the width of the tip of the short core rail 2 is about 3mm.

Embodiment 3

[0013] Embodiment 3: On the basis of Embodiment 1, the splicing method of the long and short center rails of the horizontal hidden tip type, the rail bodies of the long center rail 1 and the short center rail 2 are connected by bolts, and the long center rail 1 is connected with the short center rail 2 For the close-fitting position, cut 5mm horizontally according to the inner 1:5 slope, the long core rail 1 is within the range of close contact with the short core rail 2, and the working edge of the long core rail 1 is chamfered at 45°; the short core rail The edge of rail 2 is close to the outer 1:5 oblique, which is closely attached to the long core rail 1; the width of the tip of the short core rail is about 5mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com