Composite stabilizer for preservation of liquid cellulase

A composite stabilizer, cellulase technology, applied in the direction of enzyme stabilization, enzymes, enzymes, etc., can solve the problem of difficult to guarantee temperature, and achieve the effect of cost saving, convenient storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The stabilizer of the present invention is preferably: take cellulase, add sucrose, sodium chloride, potassium sorbate and sodium thiosulfate and mix and stir. The percentages of the weight of each raw material in the weight of the cellulase are as follows: sucrose accounts for 40%, sodium chloride accounts for 10%, potassium sorbate accounts for 0.02%, and sodium thiosulfate accounts for 0.015%.

[0009] Take 1 ton of liquid cellulase, add 400 kg of sucrose, 100 kg of sodium chloride, 0.2 kg of potassium sorbate and 0.15 kg of sodium thiosulfate and mix well to keep the cellulase activity for 2 years.

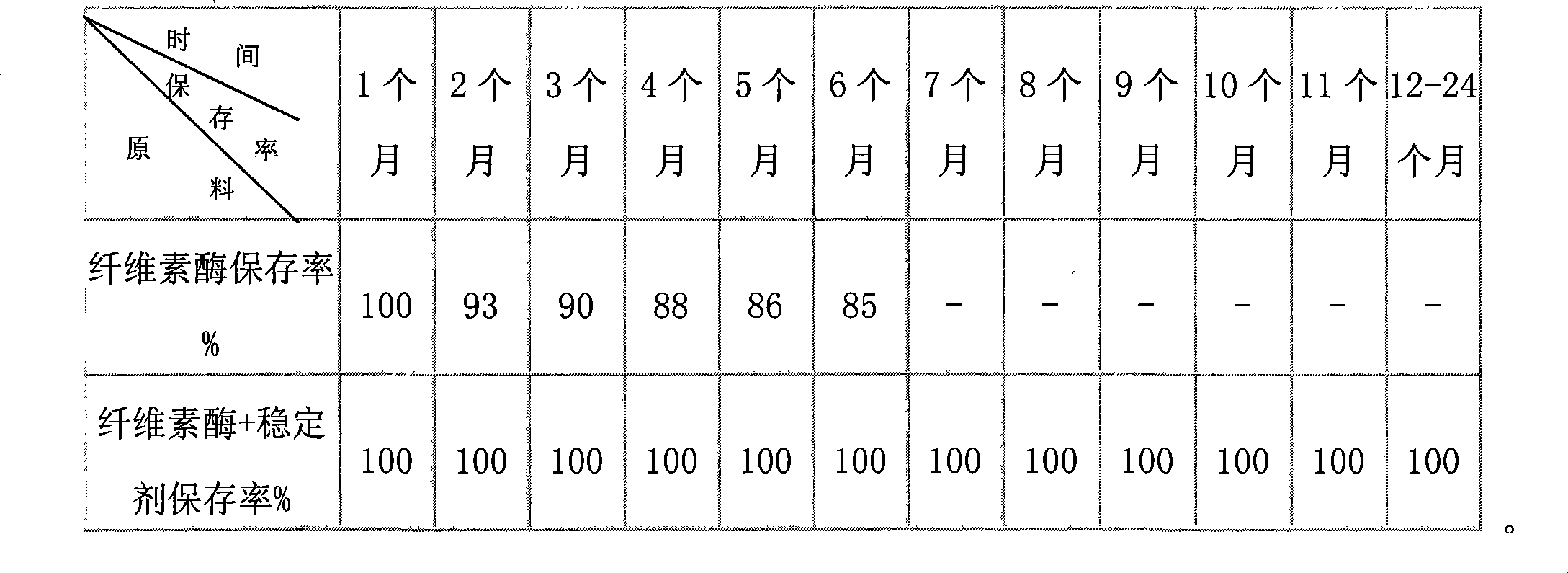

[0010] Table 1: Cellulase and the activity contrast experiment of the cellulase that adds stabilizer of the present invention

[0011]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com