Quick precise injection platform

A precise and fast technology, applied in the field of double-cylinder balanced injection platform structure, can solve the problem of high noise, achieve the effect of reducing the amount of oil return, reducing the speed of oil return, and solving the effect of excessive oil return pressure and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

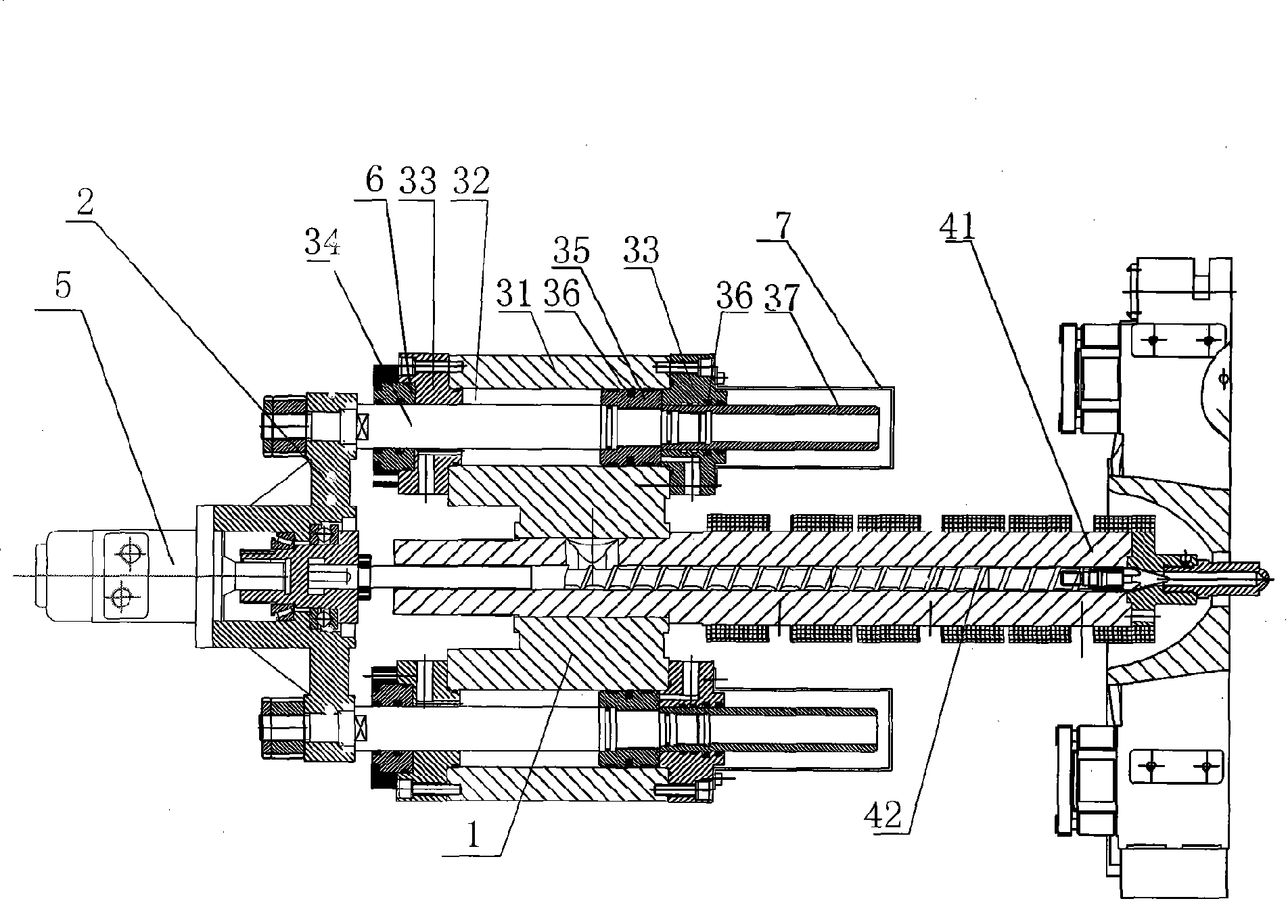

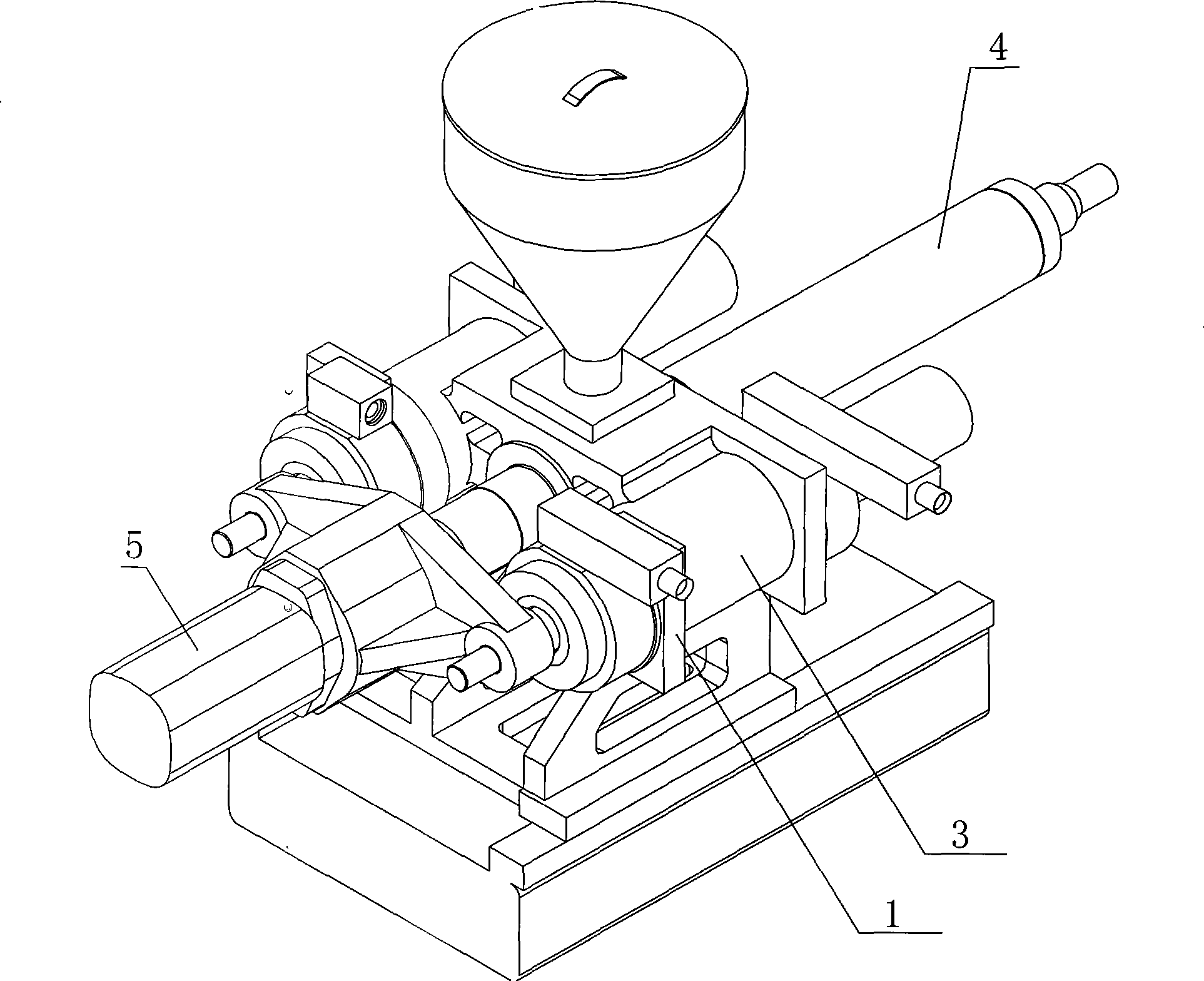

[0014] refer to figure 1 , figure 2 , the rapid and precise injection platform structure disclosed in the present invention includes an injection platform head plate assembly 1, an injection platform tail plate 2, two injection cylinder assemblies 3 and a melt cylinder assembly 4, wherein the injection cylinder assembly 3 is arranged on the injection platform head Both sides of the board assembly 1.

[0015] As shown in the figure, the injection cylinder assembly 3 used in the present invention includes a cylinder body 31, a piston chamber 32 is arranged in the cylinder body 31, a cylinder head 33 is installed at both ends of the cylinder body 31, and a piston rod is installed in the piston chamber 32 34. A piston 35 is fixedly installed on the piston rod 34, an oil seal 36 is installed between the piston 35 and the inner wall of the piston chamber 32, and the piston rod 34 passes through a cylinder head 33 at one end and is fixed on the injection tail plate 2.

[0016] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com