Water-soluble polyvinyl alcohol resin fiber and nonwoven fabric made by using the same

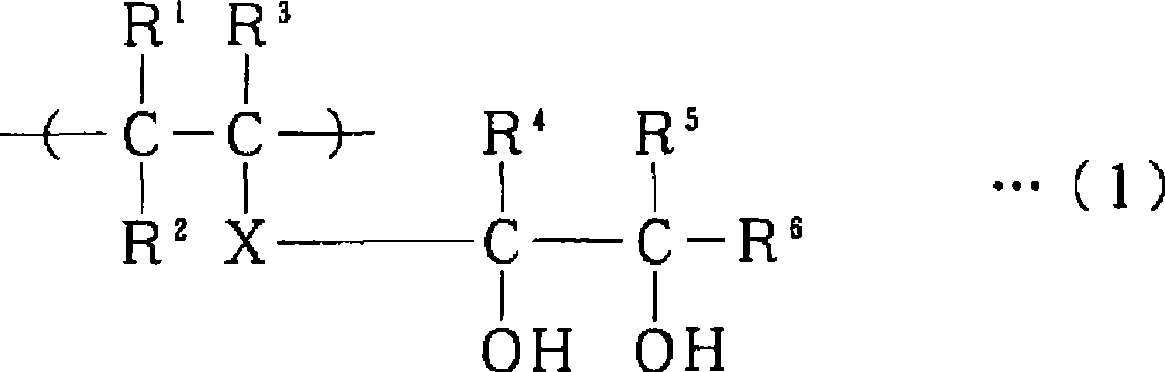

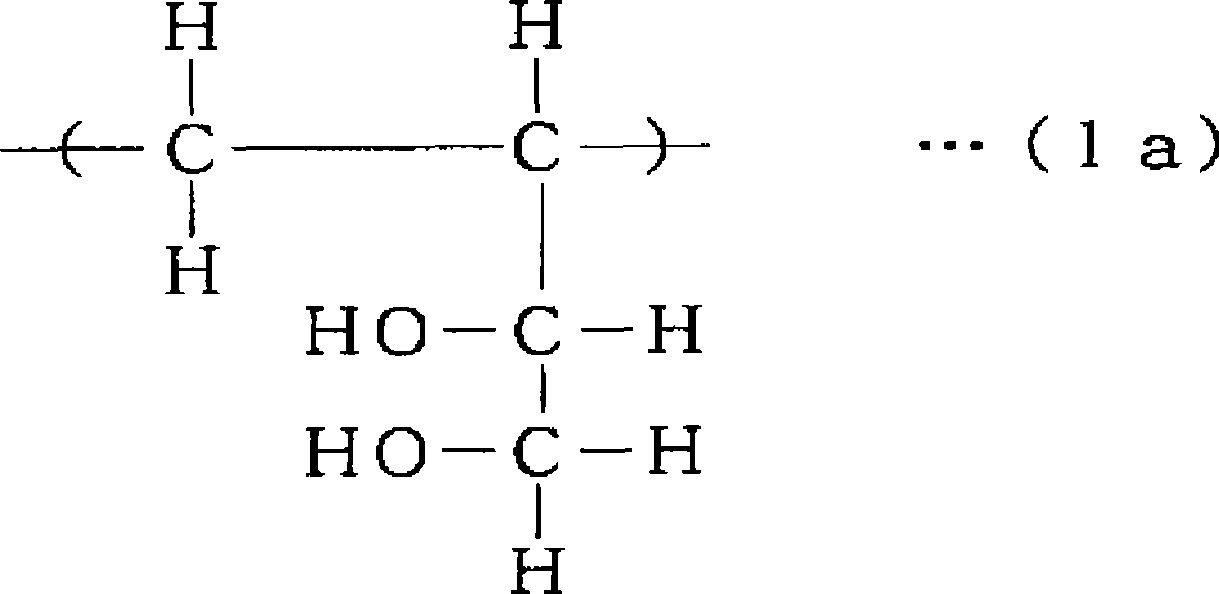

A polyvinyl alcohol-based, water-soluble technology, applied in the chemical characteristics of fibers, textiles, non-woven fabrics, etc., can solve the problems of difficult melt forming, unfavorable dissolving operations, and generation of air bubbles, and achieves anti-foaming and acetic acid odor inhibition. The effect of generating and improving fiber strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

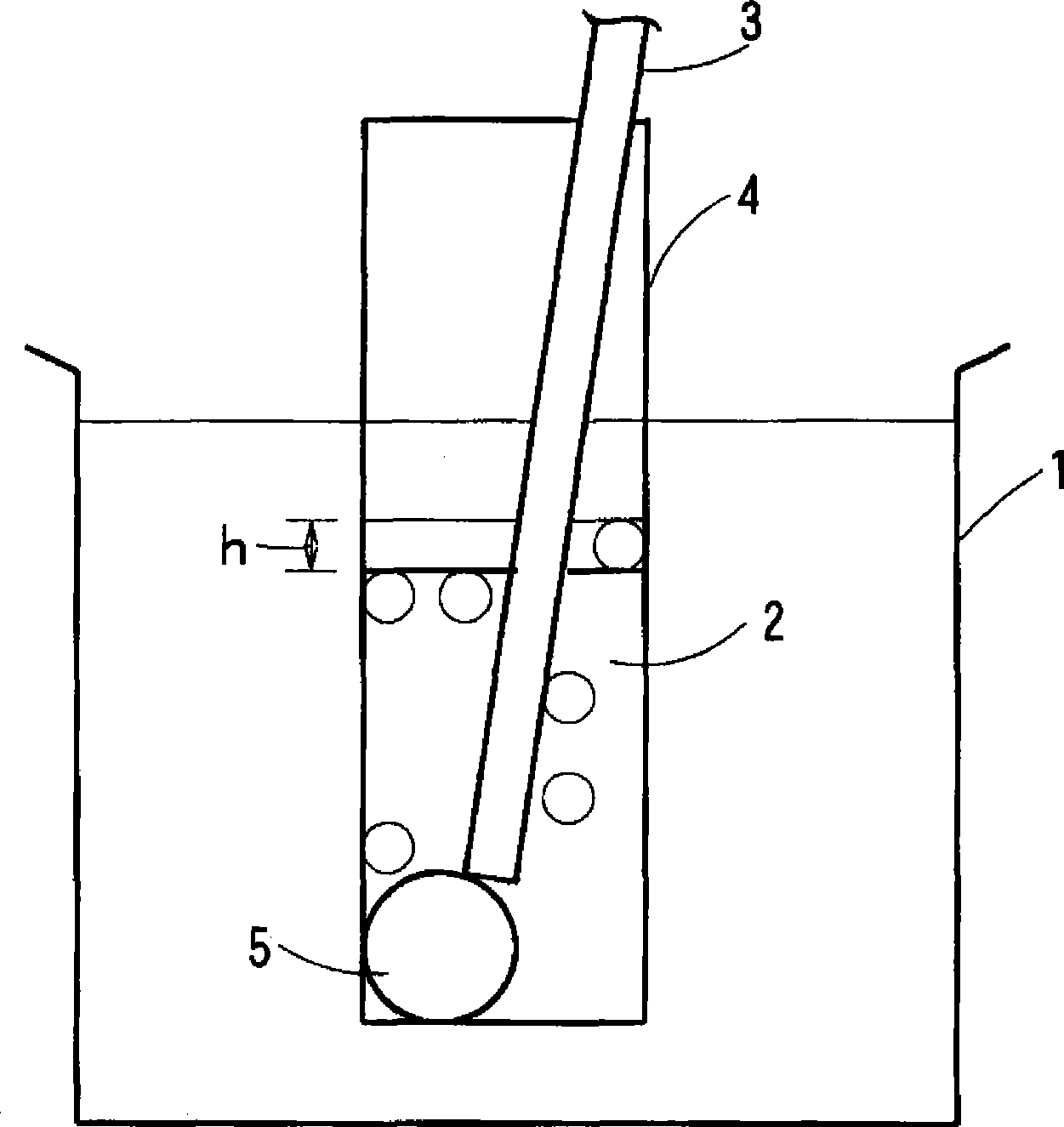

[0100] (Production of water-soluble PVA-a)

[0101] In the reaction still equipped with reflux condenser, dropping funnel, stirrer, drop into vinyl acetate 1500g, methyl alcohol 2100g, 3,4-diacetoxy-1-butene 180g (with respect to the 6 mol% acetic acid that drops into Vinyl ester), 0.05 mol% of azobisisobutyronitrile was added, and the temperature was raised under nitrogen flow while stirring to start polymerization. When the polymerization rate of vinyl acetate reaches 80%, m-dinitrobenzene is added according to the specified amount to terminate the polymerization, and then, the unreacted vinyl acetate monomer is removed from the system by blowing methanol vapor to obtain a copolymerization methanol solution of the substance.

[0102] Then, the above methanol solution was diluted with methanol, adjusted to a concentration of 35%, and then it was put into a kneader, and the temperature of the solution was kept at 40° C., while the vinyl acetate structural unit in the copolyme...

Embodiment 2

[0106] The water-soluble PVA-a was blended with 5% of glycerin as a plasticizer as a whole, and the resulting material was prepared as a fiber-forming material, and used for melt spinning. In addition, the melting point of the aforementioned fiber-forming material was 177°C.

Embodiment 3

[0108] 10% of glycerin as a plasticizer was blended with the above-mentioned water-soluble PVA-a, and the resulting material was prepared as a fiber-forming material and subjected to melt spinning. In addition, the melting point of the aforementioned fiber-forming material was 172°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com