Winding flexible strapping machine and winding flexible strapping method

A winding mechanism and winding technology are applied in the directions of weapon accessories, ammunition storage, ammunition, etc., which can solve the problems of low production efficiency, difficulty in adapting to market demand, and high production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

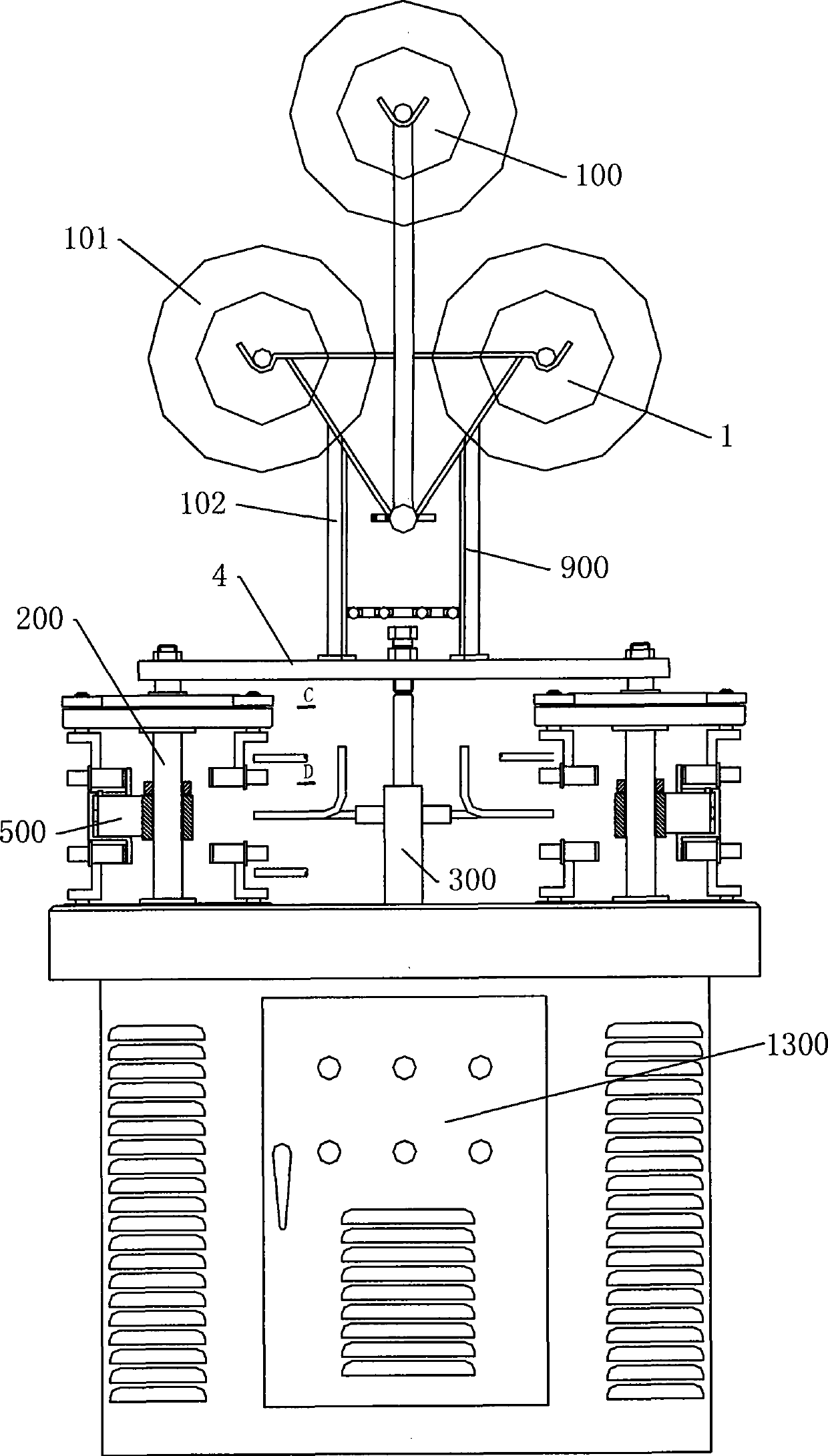

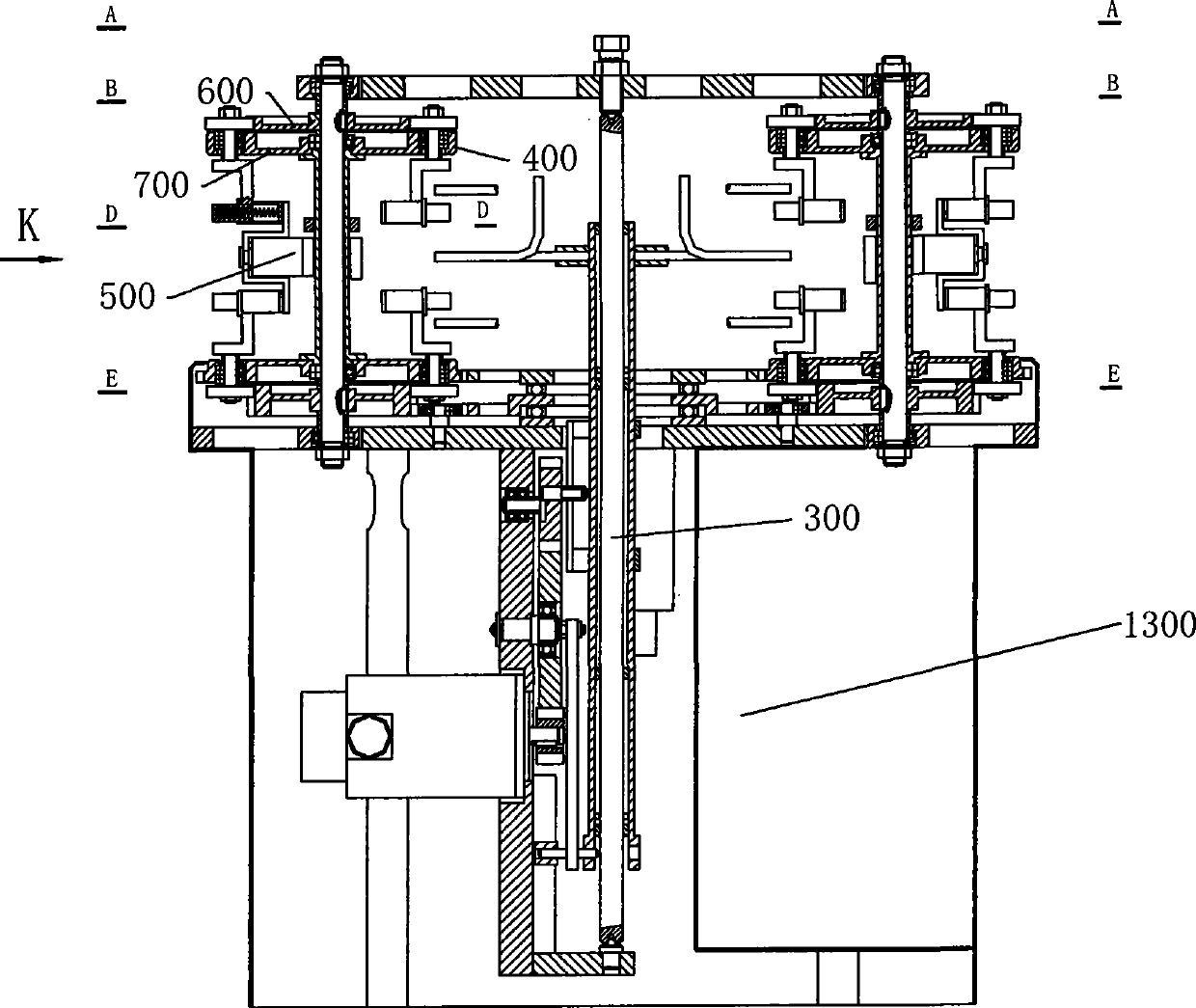

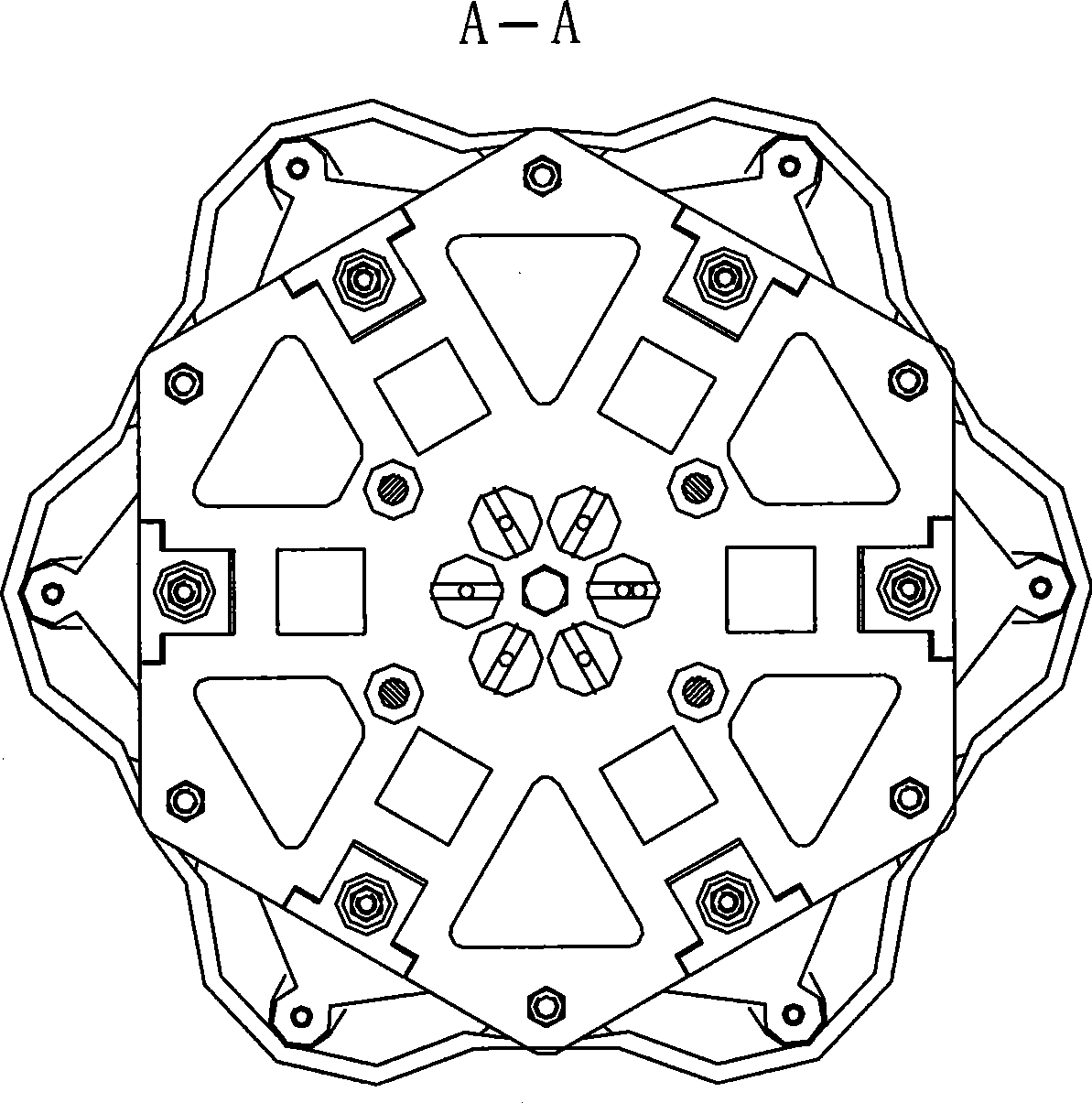

[0064] Embodiment: vertical axis turnover type "8" shape winding and beating machine

[0065] Referring to the accompanying drawings, the vertical axis rotary type "8" shaped winding and beating machine is composed of a vertical axis rotary type winding machine consisting of a pay-off mechanism 100, a winding machine host 200, an automatic control system 1300, and a frame 4 ( figure 1 ), the frame 4 is used to support and connect each component. The automatic control system 1100 includes plc (programmable logic controller), whose outputs control the actions of winding motors, epicyclic motors, indexing motors, shearing cylinders, unloading cylinders and other components.

[0066] Pay-off mechanism 100:

[0067] see figure 1 , the pay-off mechanism 100 is located on the upper part of the whole machine (it can also be placed next to the main machine), including a pay-off bracket 101, six winding reels 102, and six tensioning mechanisms, whose function is to support 6 groups (c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap