Urethane foam molded article, manufacturing method thereof, and magnetic induction foam molding apparatus

A foam molding and manufacturing method technology, applied in the direction of electromagnets, magnetic objects, electrical components, etc., can solve the problem of increased weight of polyurethane foam moldings, increased manufacturing costs, reduced sound absorption properties, heat insulation and cushioning properties and other problems, to achieve the effect of suppressing the leakage of magnetic force lines, less waste of magnetic force, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

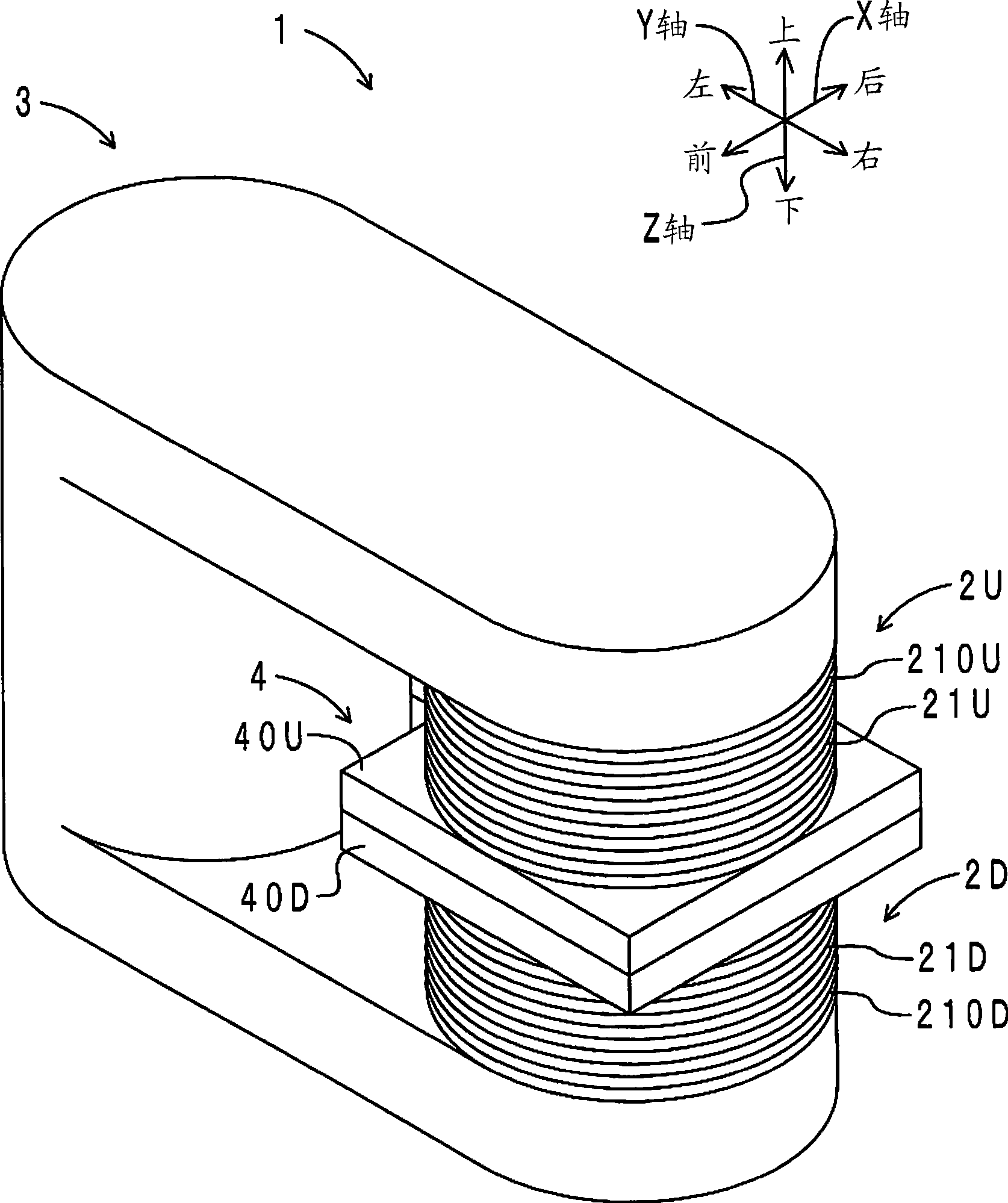

[0114] (1) Manufacture of polyurethane foam moldings

[0115]Three types of polyurethane foam moldings containing magnetic fillers as magnetic bodies were produced. First, foamable polyurethane resin raw materials were prepared as follows. 100 parts by mass of polyether polyol ("S-0248" manufactured by Sumika Bayer Urethane Co Ltd, average molecular weight 6,000, functional group number 3, OH value 28 mgKOH / g) as a polyol component was used as a crosslinked 2 parts by mass of diethylene glycol (manufactured by Mitsubishi Chemical Corporation) as an agent, 2 parts by mass of water as a foaming agent, 1 part by mass of a tetraethylenediamine-based catalyst (manufactured by Kao Corporation "No. 31"), and silicone 0.5 parts by mass of a foam stabilizer ("SZ-1313" manufactured by Japan Unika Co., Ltd.) was mixed to prepare a pre-blended polyol. Diphenylmethane diisocyanate (MDI) (“NE1320B” manufactured by BASFINOAC Polyuretan Co., Ltd., NCO=44.8 wt %) was added and mixed as a pol...

Embodiment B

[0129] (1) Manufacture of polyurethane foam moldings

[0130] Two types of polyurethane foam moldings having skin layers on one or both ends of the foam body were produced. First, a foamed polyurethane resin raw material was prepared in the same manner as in (Example A) (1) above. In addition, in this example, 2 parts by mass of a carbon-based pigment ("FT-1576" manufactured by Dainichi Seika Co., Ltd.) was mixed with the premixed polyol.

[0131] Next, MR fluid ("E-600" manufactured by Sigma Hai Chemical Co., Ltd.) was mixed with the prepared foamable polyurethane resin raw material to prepare a mixed material. 29.2 parts by mass of MR fluid were mixed with 100 parts by mass of foamed polyurethane resin raw materials obtained by mixing polyether polyol as a polyol component and MDI as a polyisocyanate component.

[0132] Afterwards, in the same manner as above-mentioned (Example A) (1), the mixed material is injected into an aluminum foaming mold (refer to the aforementione...

Embodiment C

[0148] (1) Manufacture of polyurethane foam moldings

[0149] A polyurethane foam molded article having a magnetic body oriented in a spike-like direction from one end surface to the outside and inside was produced. First, MR fluid ("E-600" manufactured by Sigma Hai Chemical Co., Ltd.) was prepared as a fluid containing a magnetic substance. Next, a foamed polyurethane resin raw material was prepared in the same manner as in the above (Example A) (1).

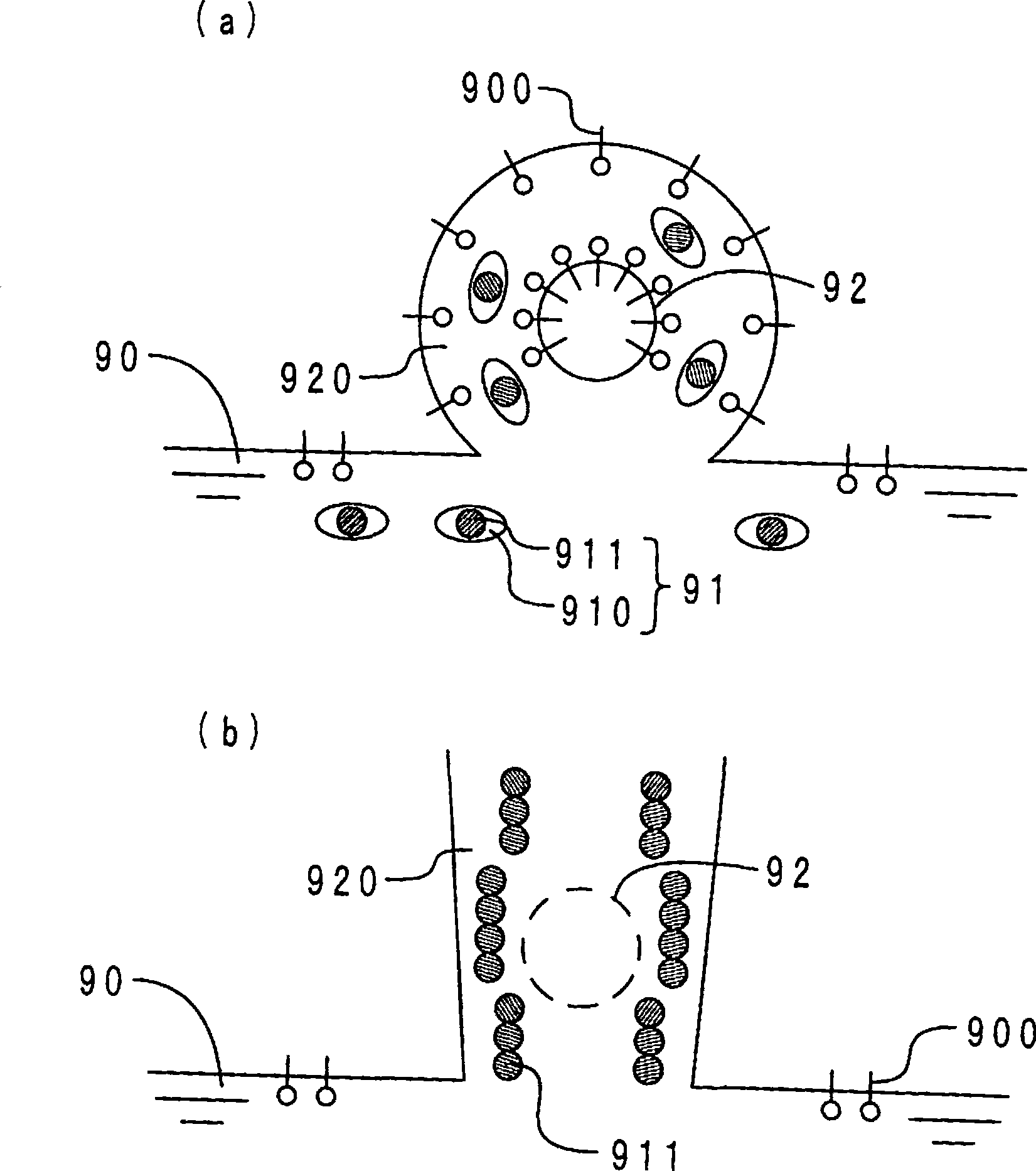

[0150] Next, the MR fluid is injected into the same aluminum foaming mold as the above (Example A) (1) (refer to the aforementioned image 3 , Figure 4) in the mold cavity (cylindrical shape with a diameter of 100mm×thickness of 20mm). The MR fluid fills up approximately as much as the bottom surface of the cavity hides. The thickness of the MR fluid is about 1mm. Next, inject the prepared foaming polyurethane resin raw material on the MR fluid and seal the mold. After that, set the foaming mold on the aforementioned ima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com