Preparation of flame-retardant polyester for preparing industrial yarn

A flame-retardant polyester and manufacturing industry technology, which is applied in the field of preparation of flame-retardant polyester to achieve the effect of decreasing and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0028] 1. Esterification process:

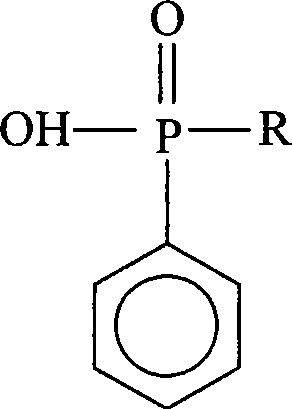

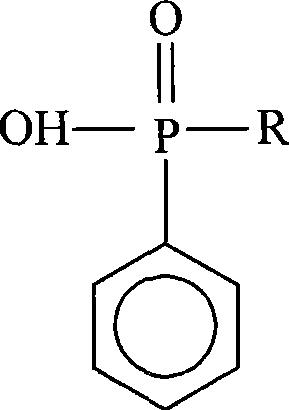

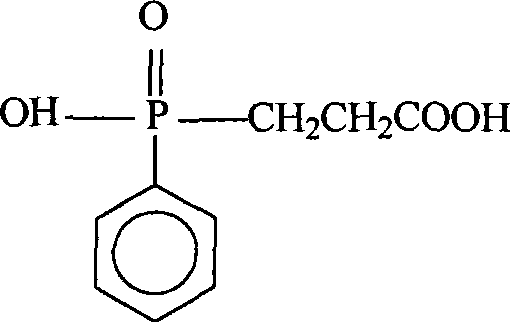

[0029] The monomer terephthalic acid, ethylene glycol, pentaerythritol and the reactive flame retardant undergo esterification reaction, and the reactive flame retardant is a compound with the following structural formula:

[0030]

[0031] The feeding ratio of raw materials is controlled respectively as follows:

[0032] In molar ratio, terephthalic acid: ethylene glycol=100:110~200;

[0033]In terms of weight ratio, terephthalic acid: pentaerythritol=100:0.01~0.12, specific data and content of pentaerythritol in flame-retardant polyester products are shown in Table 1;

[0034] In terms of weight ratio, terephthalic acid: reactive flame retardant = 100: 1.40-7.50, see Table 1 for specific data and flame retardant content in flame-retardant polyester products.

[0035] The way of adding nano-kaolin is selected before the esterification reaction. When the raw materials are beaten and mixed before the esterification reaction, the require...

Embodiment 5~8

[0042] The method of adding nano-kaolin is changed to adding before the polycondensation reaction. Firstly, nano-kaolin particles are beaten and mixed with ethylene glycol to prepare a slurry with a concentration of 20-45 wt%, and then added to the reaction system through the oligomer pipeline. All the other are with embodiment 1~4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com