Method for producing easy-tear type polypropylene packaging film

A manufacturing method and technology of polypropylene film, applied in the field of plastic packaging, can solve the problems of poor tearing effect, high cost, and difficulty in tearing out cracks, and achieve the effects of reduced tear strength, regular tearing and easy tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Present embodiment is a kind of manufacture method of easy-tear type polypropylene packaging film, has the following steps:

[0024] ①Primary stretching: take the polypropylene film that meets the hygienic requirements as the raw material, and perform unidirectional directional stretching on it, specifically, pass the polypropylene film through the surface of the heating roller with hot oil, and heat it to 130±3°C Stretching is carried out, and the stretching ratio is 3 to obtain a film material after directional stretching;

[0025] ②One-time cooling: cooling the directional stretched film material, specifically, making the directional stretched film material pass through the surface of the cooling roller with running water, so that its temperature is suddenly cooled to 25±3°C.

[0026] The film material obtained after a cooling treatment is detected, its thickness is 70 μm, the elongation at break in the stretching direction is 125%, the elongation at break in the uns...

Embodiment 2 to Embodiment 6

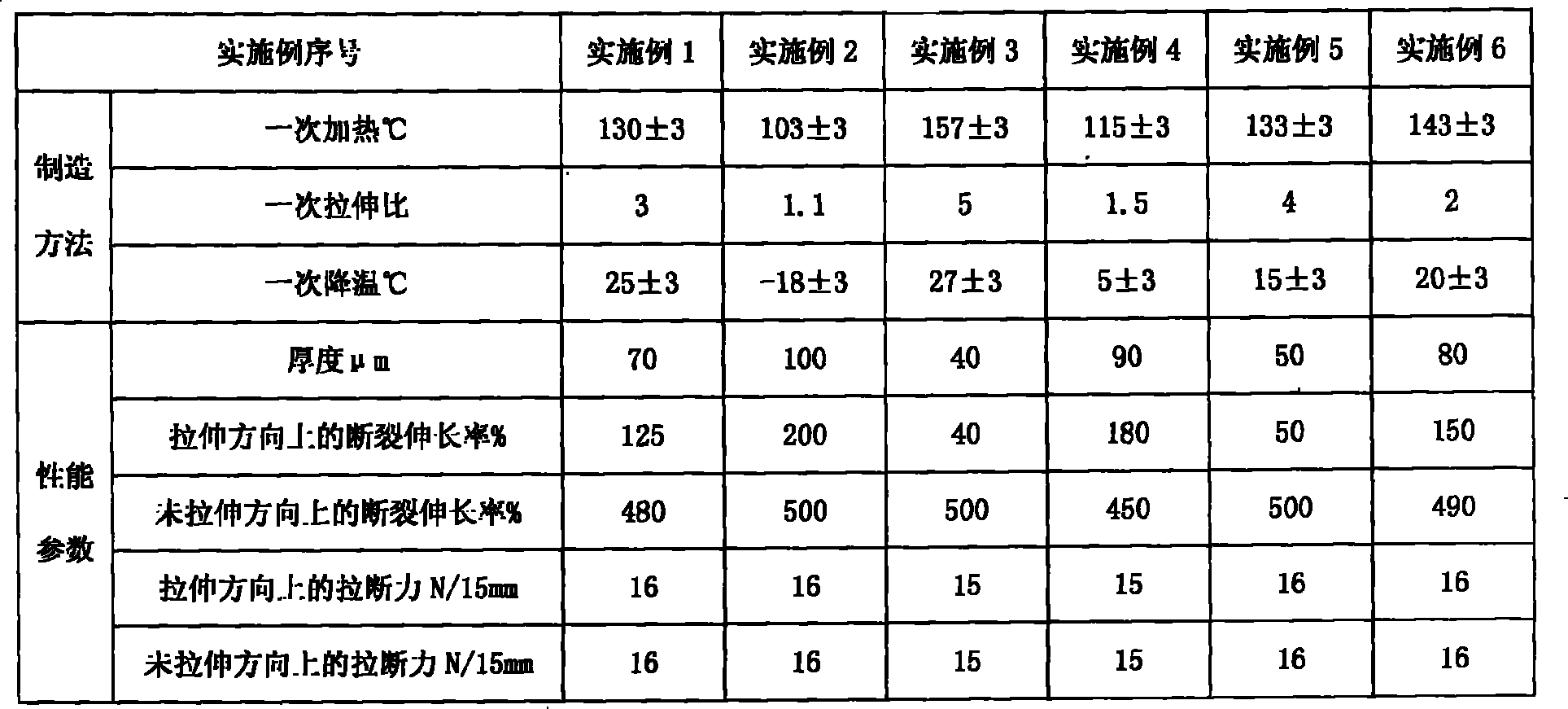

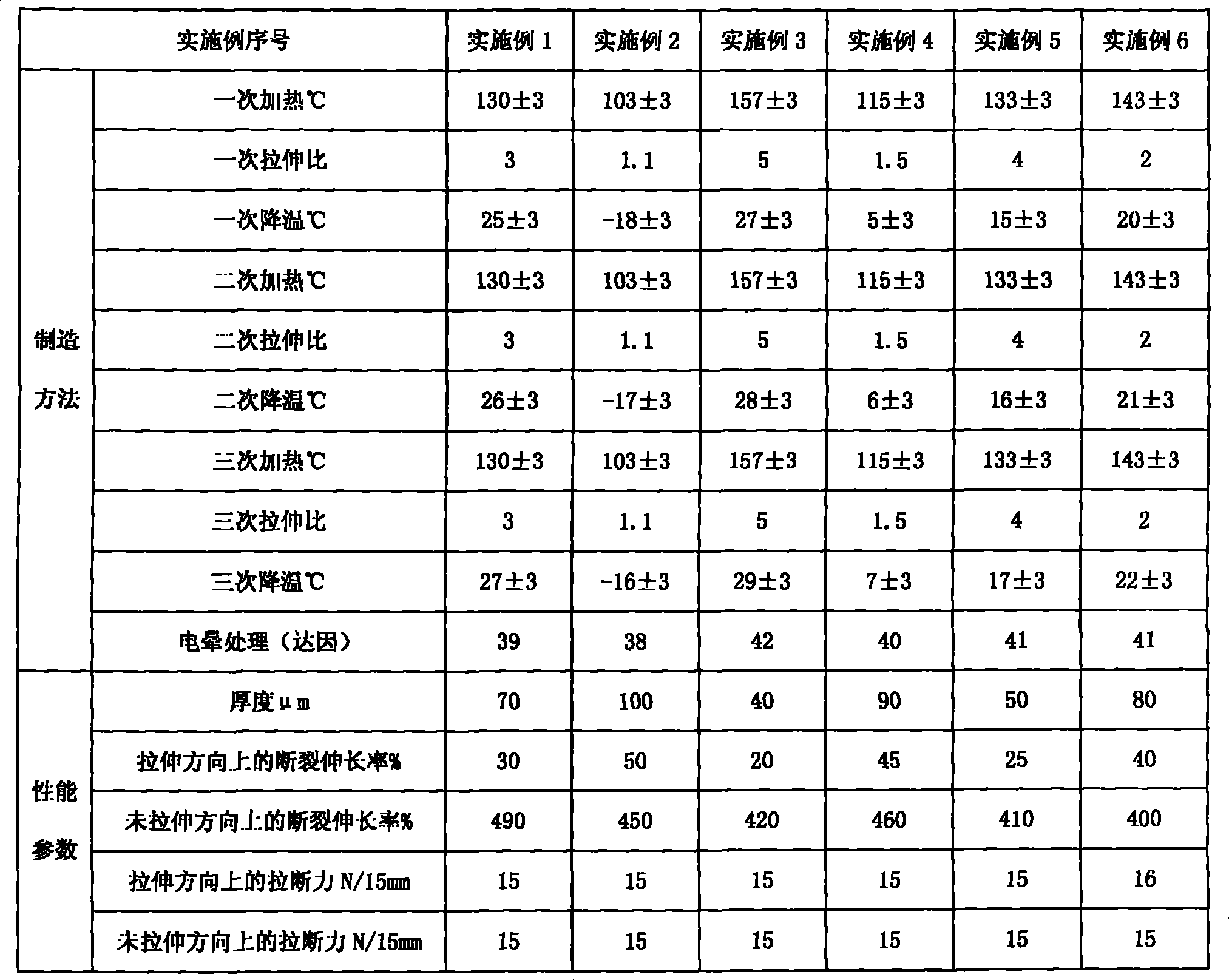

[0028] Embodiment 2 to embodiment 6 are basically the same as embodiment 1, and the difference is: each embodiment in embodiment 2 to embodiment 6 detects the easy-to-tear type polypropylene packaging film obtained at last, and its various properties The parameters are: the temperature at which the polypropylene film is heated is different, and the stretching ratio is also slightly different. In addition, the temperature at which it is quenched is also different. See Table 1 for specific parameters.

[0029] Table 1

[0030]

[0031] The tearing test was carried out on the polypropylene packaging film finally obtained in the above-mentioned Examples 1 to 6, and the tear was basically linear along the stretching direction, and it was an easy-to-tear polypropylene packaging film.

Embodiment 7

[0033] Present embodiment is a kind of manufacture method of easy-tear type polypropylene packaging film, has the following steps:

[0034] ①Primary stretching: take the polypropylene film that meets the hygienic requirements as the raw material, and perform unidirectional directional stretching on it, specifically, pass the polypropylene film through the surface of the heating roller with hot oil, and heat it to 130±3°C Stretching is carried out, and the stretching ratio is 3 to obtain a film material after directional stretching;

[0035] ②One-time cooling: cooling the directional stretched film material, specifically, making the directional stretched film material pass through the surface of the cooling roller with running water, so that its temperature is suddenly cooled to 25±3°C.

[0036] ③Secondary Stretching: Stretch it in one direction. Specifically, pass the polypropylene film through the surface of a heating roller with hot oil, heat it to 130±3°C and then stretch i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Breaking force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com