Internal combustion engine

A technology for internal combustion engines and crankshafts, applied in the field of internal combustion engines, can solve the problems of engine efficiency reduction, loss, and engine work efficiency reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

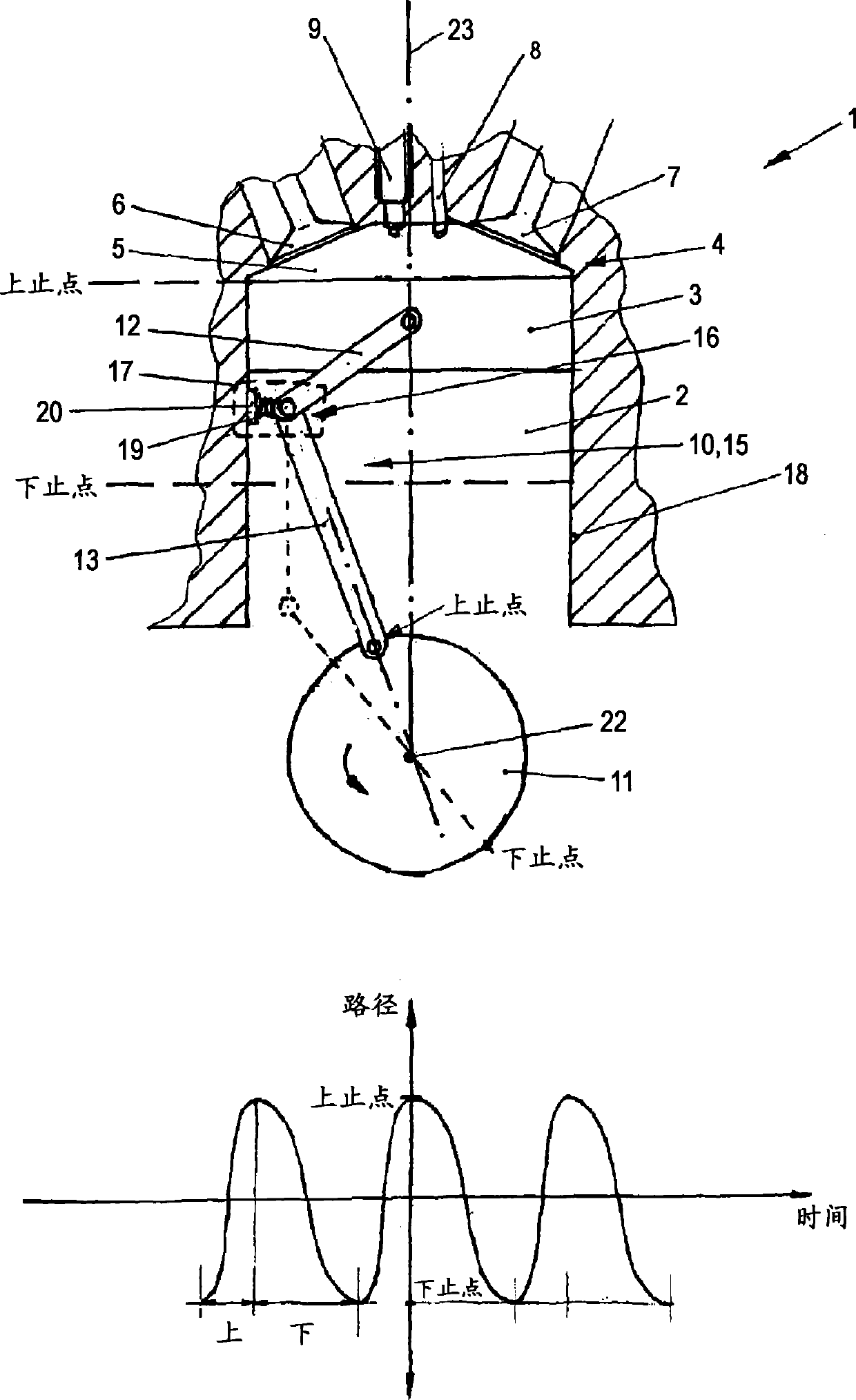

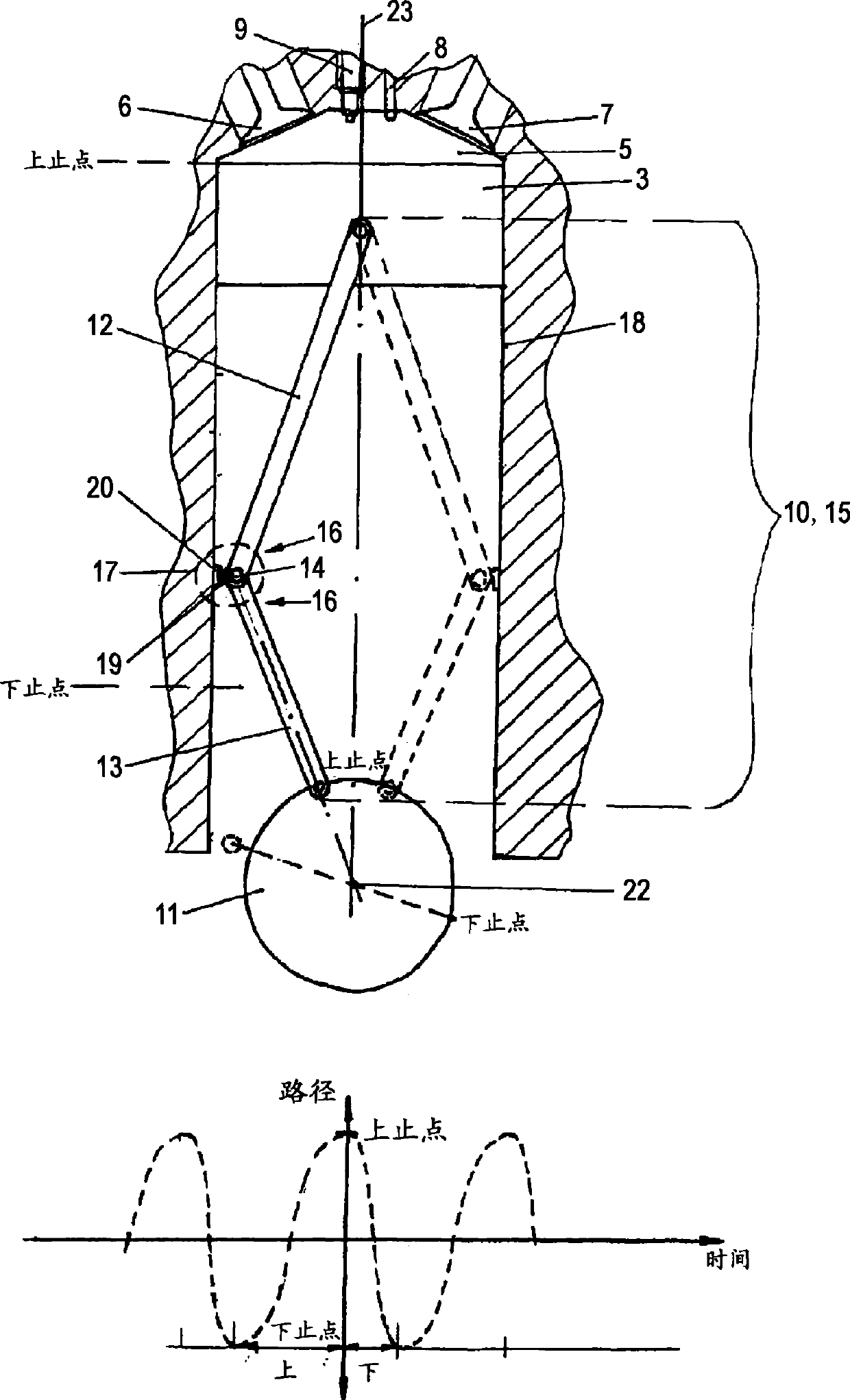

[0023] figure 1 A sectional view of a cylinder 2 of an internal combustion engine 1 in a first embodiment of the invention is shown. A piston 3 that can slide up and down in the cylinder 2 is arranged in the cylinder 2 . The piston 3 and the upper end of the cylinder 2 and the cylinder head 4 form a combustion chamber 5 . The cylinder head 4 is provided with an intake valve 6 and an exhaust valve 7 for introducing air and exhausting exhaust gas, a nozzle 8 for injecting fuel, and a spark plug 9 for igniting a mixture gas.

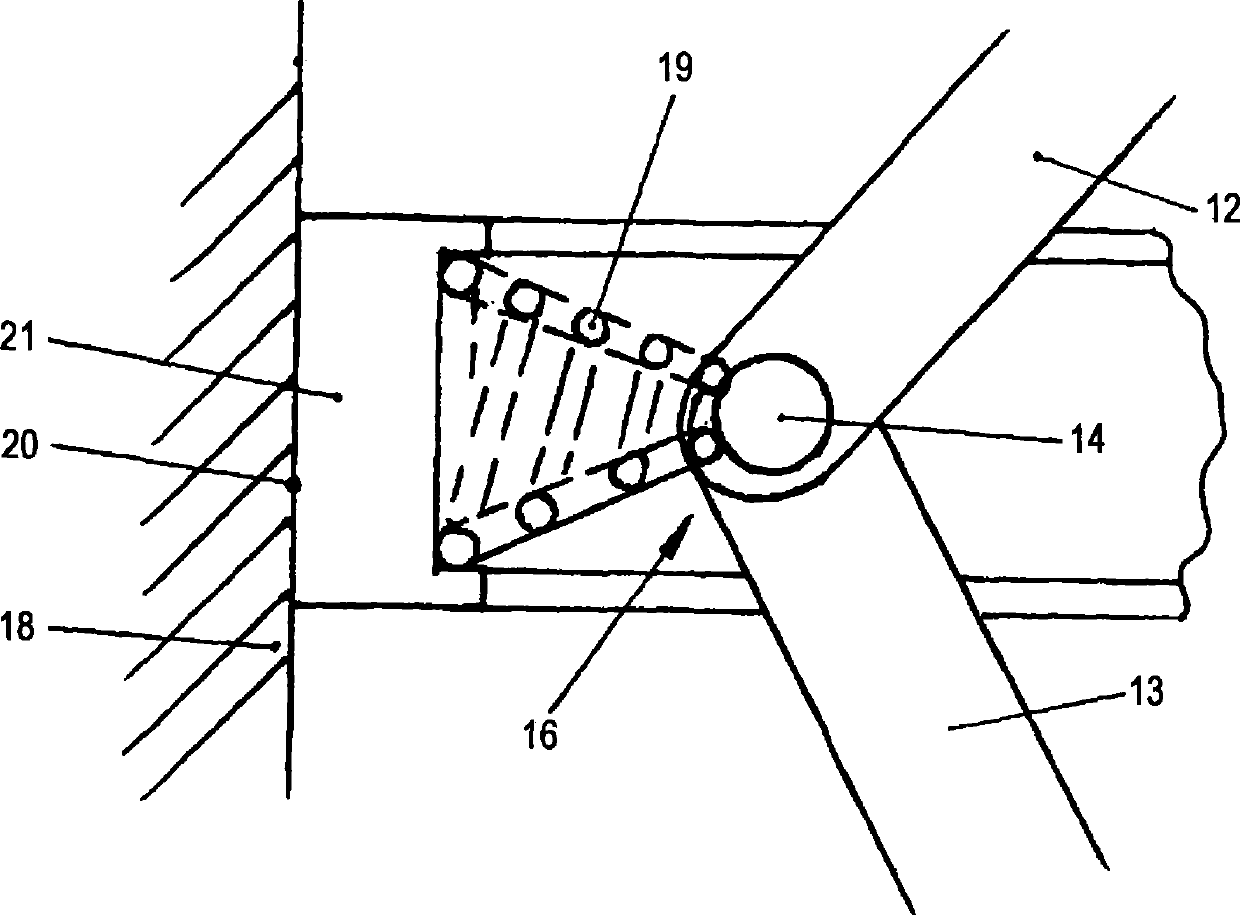

[0024] The piston 3 transmits the load generated by the gas mixture explosion to the crankshaft 11 through the adjusting device 10 . In this specific embodiment, the adjusting device 10 comprises a piston rod assembly 15 having two piston rods 12 , 13 articulated to each other via a rotating shaft 14 . The first piston rod 12 in this specific embodiment is hingedly connected with the piston 3 . Alternatively, the rod 12 can also be fixed on or connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com