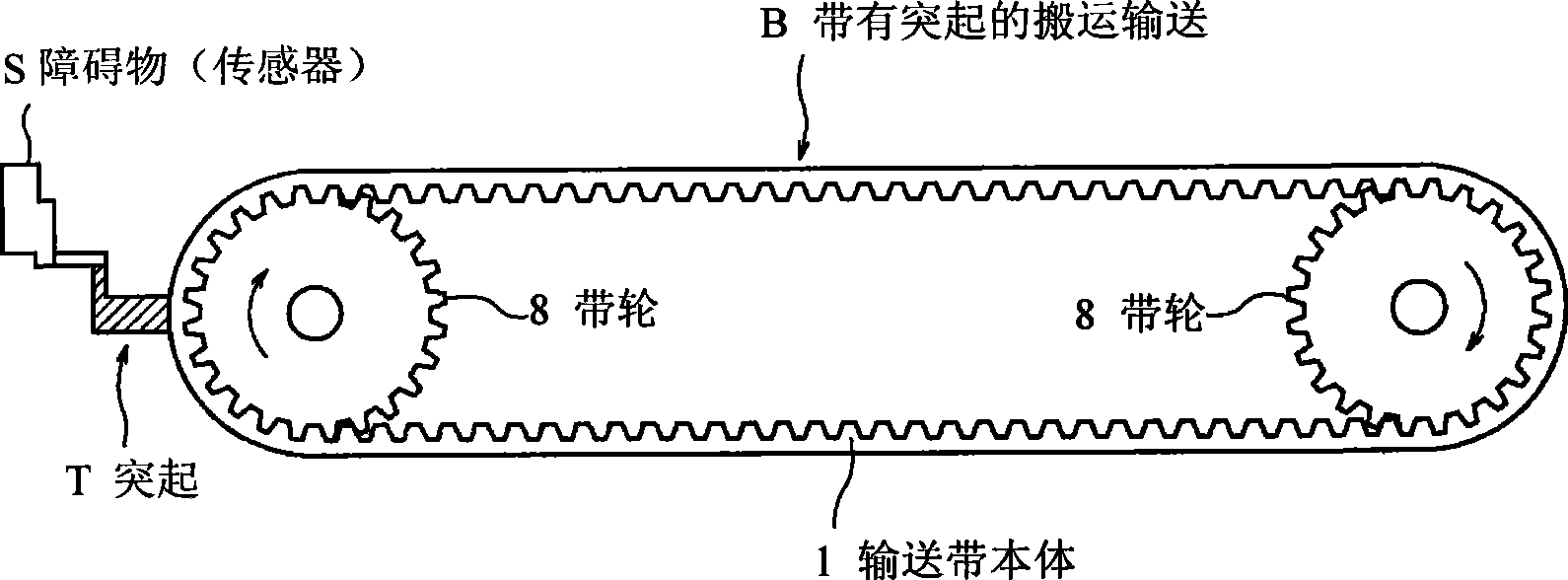

Belt with projection

A conveyor belt and support technology, applied in the field of conveying conveyor belts, can solve the problem of not being able to convey the direction, and achieve the effects of reducing the risk, increasing the bonding strength, and increasing the rotational resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2

[0178]

[0179] Figure 7 Among (a) to (d), examples of Example 1 are shown.

[0180] This embodiment is an example of piercing and inserting the U-shaped needle-shaped body relative to the convex support portion along the length direction of the conveyor belt. The pricking operation uses a pliers-shaped clamp to hold the U-shaped curved part to keep the state stable and complete the pricking operation reliably at the specified position.

[0181] In this example, a metal U-shaped needle 12 (figure (b)) made of a wire 11 (figure (a)) with a width of 0.5 mm and a thickness of 0.3 mm was bent to an inner width of 2 mm and a leg length of 5 mm. As the wire, for example, a staple (JIS G6035) wire of a stapler can be used. When the front end is made into an acute angle, the piercing property can be improved.

[0182] This U-shaped needle-shaped body 12 is pierced and inserted into the convex support member 4 (figure (c)). The insertion position is centered on the central part ...

Embodiment 2

[0185] Figure 7 (e) shows an example of Embodiment 2.

[0186] This embodiment is an example in which the front end side of the U-shaped needle-like body protruding through the piercing is bent to intersect the two ends in the first embodiment to provide an intersecting portion 13 . Bending can also bend both sides, or bend one side, or twist. In this example, the bent portion, that is, the leg length may also be lengthened.

Embodiment 3

[0201] It is opened in the central part of the convex support part 4 along the length direction of the conveyor belt The through-hole 15 is an example in which one needle-shaped body 14 is stabbed and inserted in other parts.

[0202] In this example, as a result of the fall recovery test, similar to the examples 1 and 2, the recovery property was confirmed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com