Directly-drive ball top type loudspeaker

A loudspeaker, the most direct technology, applied in the field of structural improvement of dome speakers, can solve the problems of difficult sound film processing, high-frequency response degradation, and sensitivity drop, so as to improve high-frequency response characteristics, reduce vibration quality, and eliminate weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

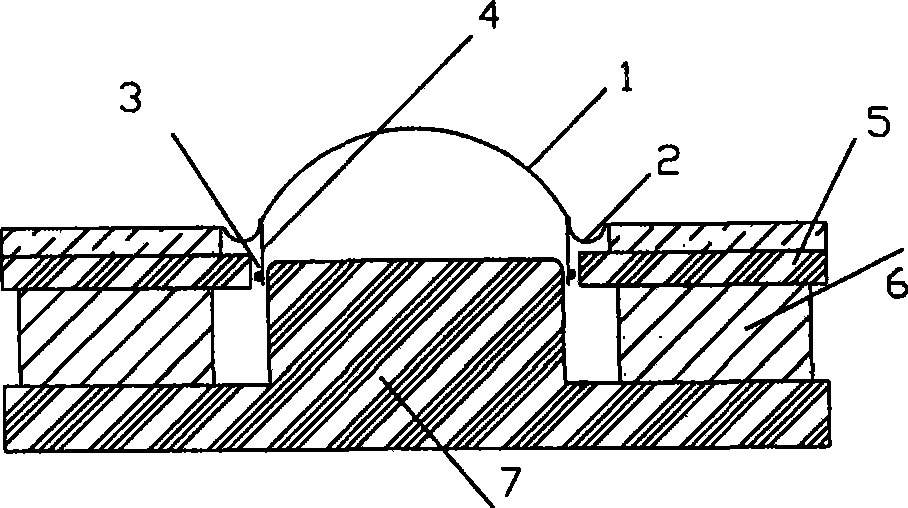

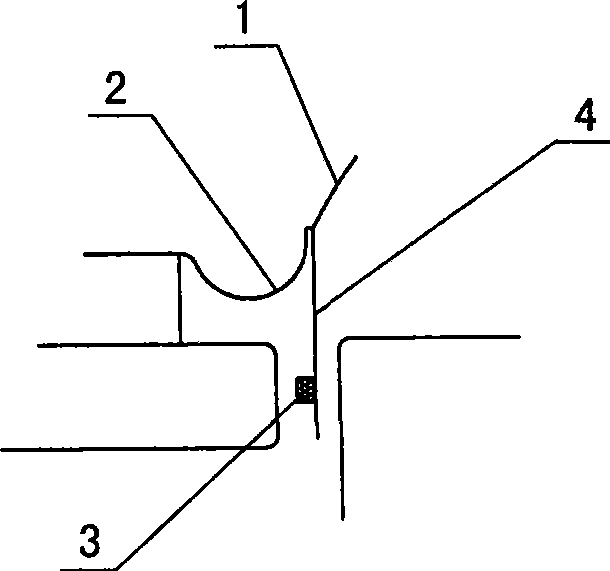

[0031] The structure of this direct drive dome loudspeaker embodiment is as follows image 3 As shown, it includes the magnetic circuit structure of the loudspeaker composed of T-shaped iron parts 7, annular permanent magnet steel 6, and annular magnetic conductive sheet 5. It has a convex dome-shaped sound membrane 1 and its connected concave fold ring 2. A wire-wound voice coil 3 is directly formed on the sound membrane surface at the junction of the top sound membrane 1 and the concave fold ring 2 (such as Figure 4 As shown), the convex dome sound membrane 1 is to use the same 28-core silk (or fabric) dome sound membrane of the traditional dome speaker, in which a convex dome is in the middle, and the outside is anti-concave The semicircular ring 2 is made of cloth and heat-pressed after resin treatment. The diameter of the connection between the convex ball top sound film 1 and the concave fold ring 2 is about 28mm, and there is a corner at this place, where a 0.06mm dia...

Embodiment 2

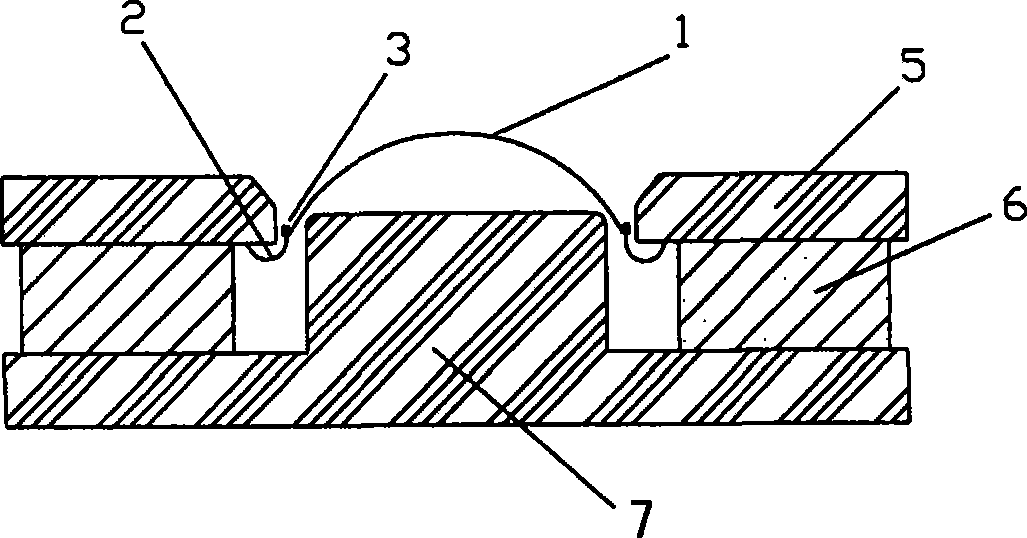

[0033] The magnetic circuit structure of the embodiment of the direct drive dome speaker is basically the same as that of Embodiment 1, and has the substantially same convex dome-shaped sound membrane 1 and its connected concave folding ring 2, where the convex dome sound membrane 1 and the A wire-wound voice coil 3 is directly formed on the surface of the sound membrane at the junction of the concave fold ring 2, and the wire-wound voice coil 3 is braided into five enameled wires with a diameter of 0.06 mm on the fabric dome sound membrane 1 to form a braided Wirewound voice coils (such as Figure 7 shown).

Embodiment 3

[0035] The structure of this direct drive dome loudspeaker embodiment is as follows Figure 8 As shown, it includes a magnetic circuit structure composed of a magnetic pole plate 9 and two magnetic steels (upper magnetic steel 8 and lower magnetic steel 10). Combined, a magnetic circuit for the loudspeaker is formed with radial magnetic fields converging near the sides of the pole plates. An iron flat plate 11 is arranged below the lower magnetic steel to strengthen the magnetic field and reduce magnetic leakage. It also has a convex dome-shaped sound film 1 and its connected concave fold ring 2. The sound film surface at the junction of the convex dome sound film 1 and the concave fold ring 2 is fixed with a wire-wound voice coil 3. The wire-wound voice coil 3. Fix it directly at this place with a pre-wound coil. The convex dome sound film 1 is to use the same 28-core silk (or fabric) dome sound film of the traditional dome speaker, in the middle of which is A convex dome, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com