Method for using SBR for quick start of continuous flow double sludge denitrification dephosphorization process

A technology of denitrification phosphorus removal and quick start, which is applied in the direction of aerobic and anaerobic process treatment, and can solve problems such as slow start of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

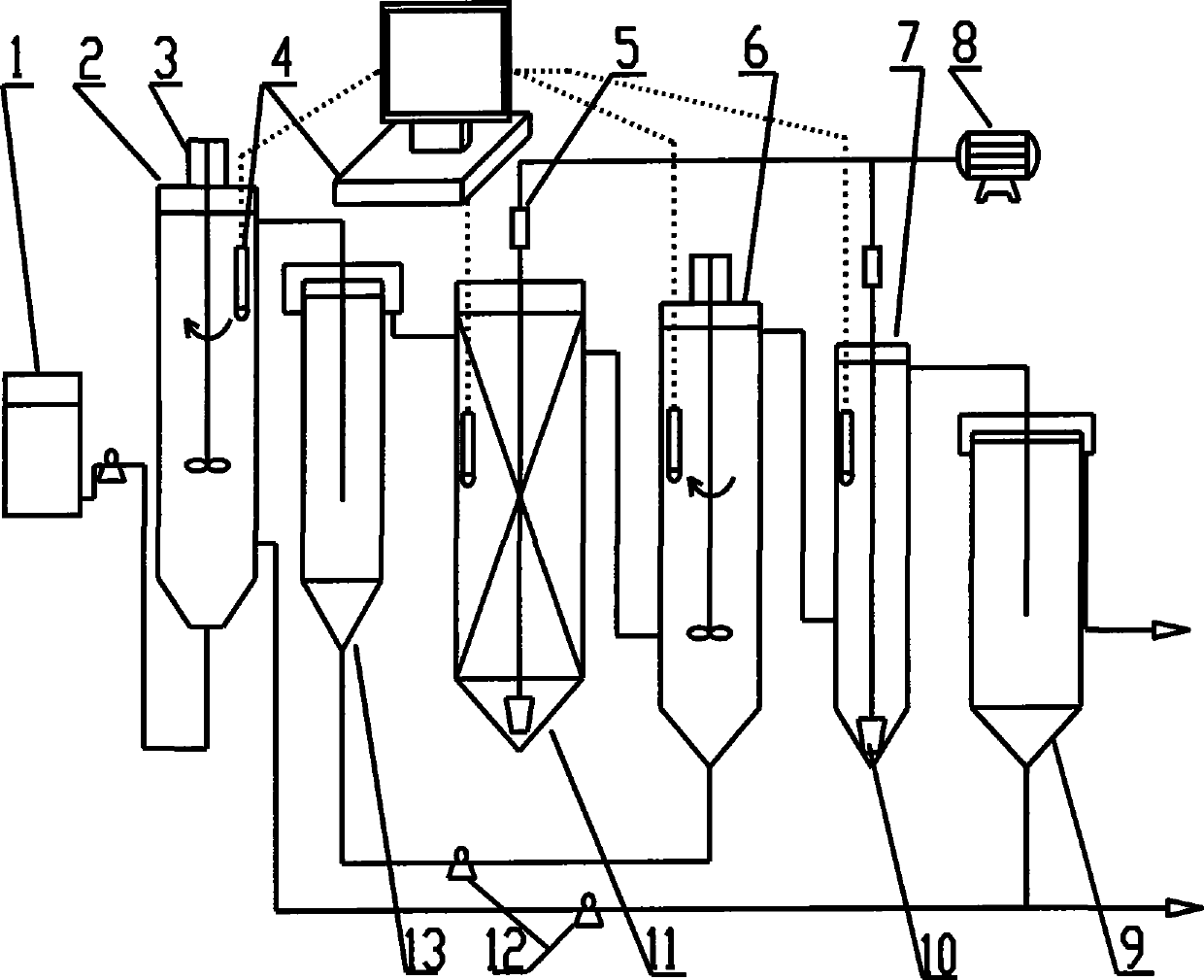

Image

Examples

specific Embodiment approach

[0028] The method of SBR for rapid start-up of continuous-flow double-sludge denitrification and phosphorus removal process can be used to prepare the start-up process of a sewage treatment plant adopting double-sludge denitrification and phosphorus removal process or to study a test device for double-sludge denitrification and phosphorus removal process. Its specific implementation method is:

[0029] First, inoculation of phosphorus removal sludge from a sewage treatment plant is carried out in two stages in an SBR reactor with a suitable volume. In the first stage, A / O (anaerobic / aerobic) mode is adopted for intermittent operation. In the SBR reactor, add seed mud and domestic sewage, anaerobically stir for 4 hours, then aerate for 3 hours, settle and drain for 30 minutes, run 3 cycles a day, and control the DO (dissolved oxygen) of the mixed solution at: 2-5mg / L. When the removal rate of phosphorus reaches more than 85%, it proves that the aerobic phosphorus accumulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com