Flexible circuit board

A technology of flexible circuit boards and conductive materials, applied in circuit devices, printed circuits, printed circuits, etc., can solve problems such as inability to transmit high-speed differential signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

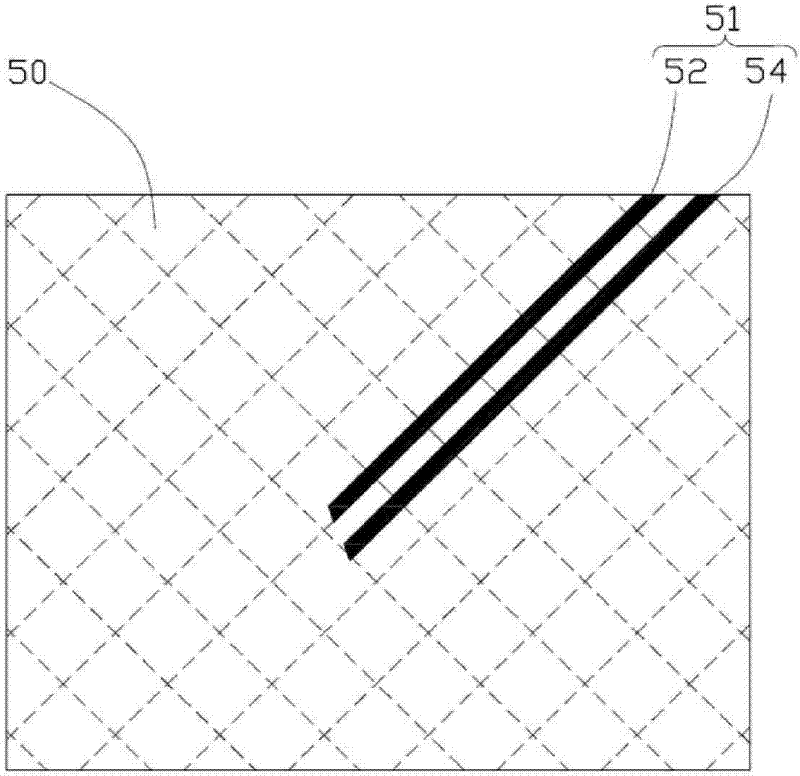

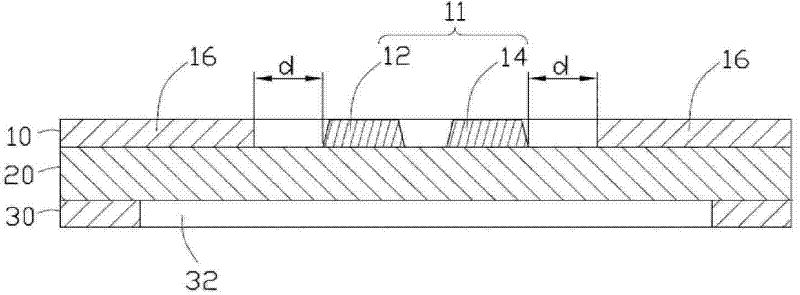

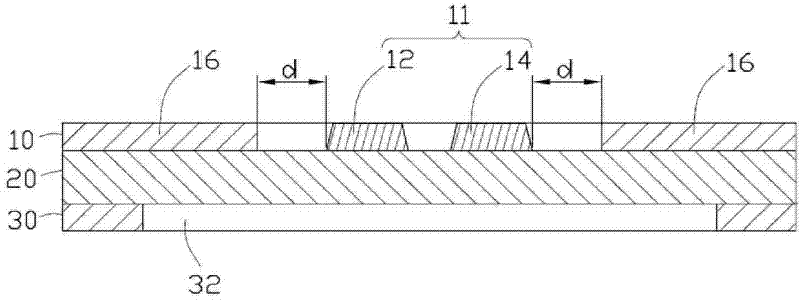

[0011] Please refer to figure 2 A preferred embodiment of the flexible circuit board of the present invention includes a signal layer 10 and a ground layer 30 , and a layer of insulating medium 20 is filled between the signal layer 10 and the ground layer 30 . A differential pair 11 includes two differential transmission lines 12 and 14 and is routed on the signal layer 10 . The part of the ground layer 30 corresponding to the bottom of the differential transmission lines 12 and 14 is hollowed out to avoid the problem of low impedance of the transmission line caused by the distance between the upper differential pair 11 and the lower ground layer 30 being too close. figure 2 The rectangular hollowed out area 32 in the center of the ground layer 30 is the copper skin hollowed out area. On the signal layer 10, a grounding conductive material equal in length to the differential pair 11 is provided in parallel on both sides of the differential pair 11. In this preferred embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com