Light stabilizer 298 and manufacturing process thereof

A technology of light stabilizer and manufacturing process, which is applied in the field of light stabilizer and its manufacturing process, can solve the problems of difficult synthesis, easy migration, and affecting the application range, etc., achieve remarkable effect, retain light stability, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

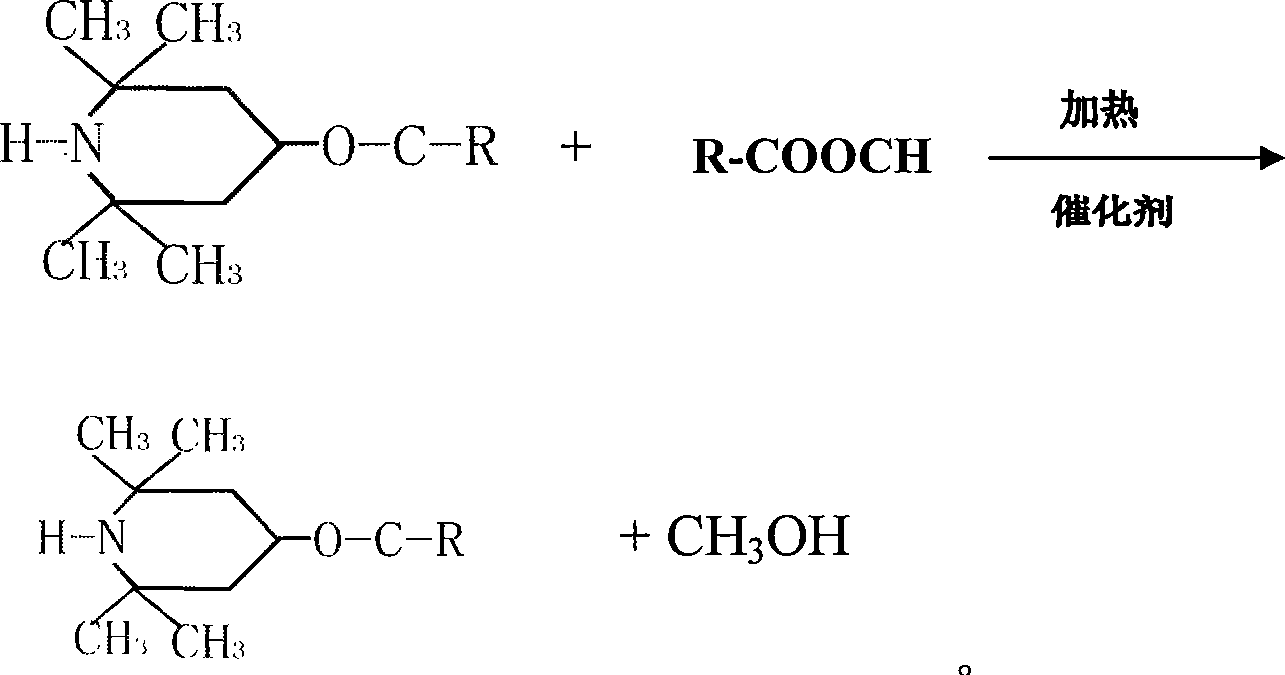

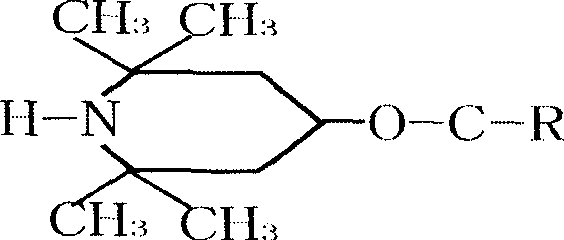

Method used

Image

Examples

Embodiment 1

[0018] Preparation

[0019] (a) In a 500ml reaction flask equipped with a condenser, reflux tube, thermometer, stirrer, dropping funnel and nitrogen inlet, 2,2,6,6-tetramethyl Put piperidinol, 0.3mol (87g) methyl oleate, and 60g solvent petroleum ether into the reactor, start the agitator at 110°C, and start heating the reactor at the same time, first raise the temperature to about 110°C for dehydration, and dehydration is completed. Then add 0.8g of supported tetrabutyl phthalate catalyst, raise the temperature to 120-125°C to reflux for demethanolization reaction, and when the extracted methanol reaches the theoretical amount, take a sample for analysis and if it is qualified, the synthesis is completed.

[0020] (b) post-treatment: cool the material synthesized in (a) and add 5g of activated carbon, reflux for 2 hours, heat filter the loaded tetrabutyl phthalate catalyst and activated carbon with a Buchner funnel at 85-90°C, and filter. Begin to remove petroleum ether with...

Embodiment 2

[0024] (a) In a 500ml reaction flask equipped with a condenser, reflux tube, thermometer, stirrer, dropping funnel and nitrogen inlet, 2,2,6,6-tetramethyl Put piperidinol, 0.3mol (87g) methyl oleate, and 60g solvent petroleum ether into the reactor, start the agitator at 110°C, and start heating the reactor at the same time, first raise the temperature to about 110°C for dehydration, and dehydration is completed. Then add 0.5g of tetrabutyl phthalate catalyst, heat up to 120-125°C and reflux for demethanolization reaction. When the extracted methanol reaches the theoretical amount, take a sample for analysis and if it is qualified, the synthesis is completed.

[0025] (b) Post-treatment: add 100g of water to the synthesized material in (a), wash it once, add 5g of activated carbon, reflux at 105-110°C for dehydration and dehydration, and use a Buchner funnel to filter at 85-95°C to complete the filtration , began to remove petroleum ether with a circulating water vacuum pump u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com