Metal solder pad welding method

A welding method and metal pad technology, applied in the field of metal pad welding, can solve the problems that the welding temperature affects the reliability of product quality, the reliability of welding products is low, and the ideal efficiency cannot be achieved, so as to solve the problem of difficult alignment accuracy control, The effect of eliminating hidden dangers of quality and reducing the influence of uncontrollable human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The features and advantages of the present invention will be described in detail with reference to the accompanying drawings.

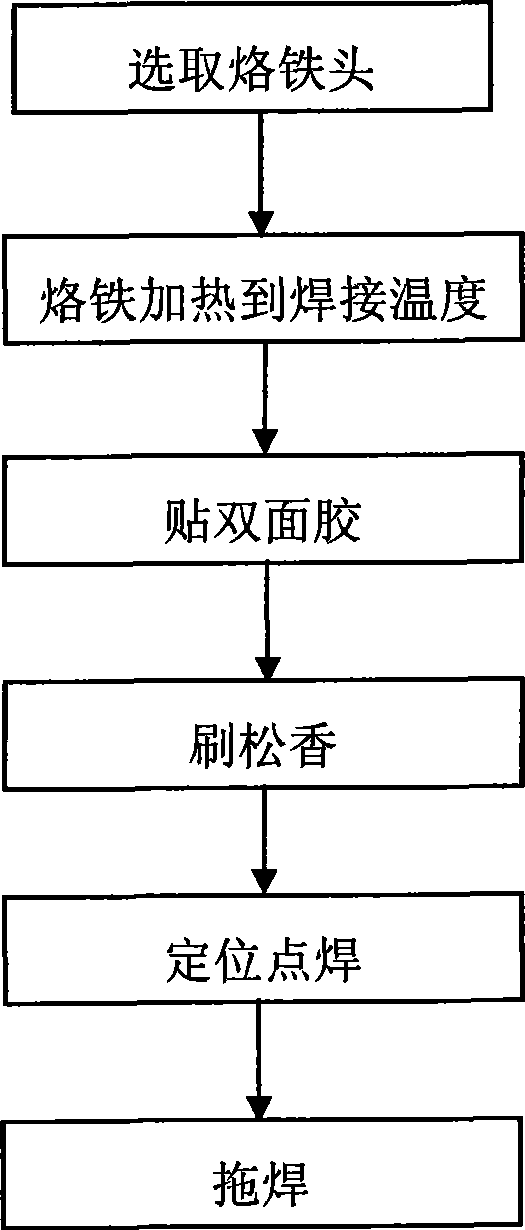

[0054] Please refer to figure 1 , the welding process of the present embodiment is implemented according to the following steps:

[0055] 1. Select the tip of the soldering iron

[0056] This embodiment adopts a reheating soldering iron with adjustable temperature and extremely fast reheating speed. The selection of the tip of the soldering iron depends on the length of the metal pad used in the soldering, as shown in the following table:

[0057] a. The horseshoe-shaped soldering iron is about 1.1-1.5:1 in ratio of the diameter of the outer circle of the soldering iron head to the size of the metal pad;

[0058] b. The ratio of the oblique soldering iron tip to the pad contact position and the metal pad is about 0.4~1.1:1;

[0059] c. The ratio of the length of the outer end of the soldering iron tip to the size of the metal pad is about ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com