On-line real-time optical fiber grating fire monitoring system

A fiber grating and monitoring system technology, which is applied to electric fire alarms, measuring devices, measuring heat, etc., can solve the problems of inability to predict the temperature change process of disaster prevention sites, expensive demodulators, and limited application range, etc. problem, to achieve the effect of online real-time rapid fire monitoring, fast demodulation speed and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

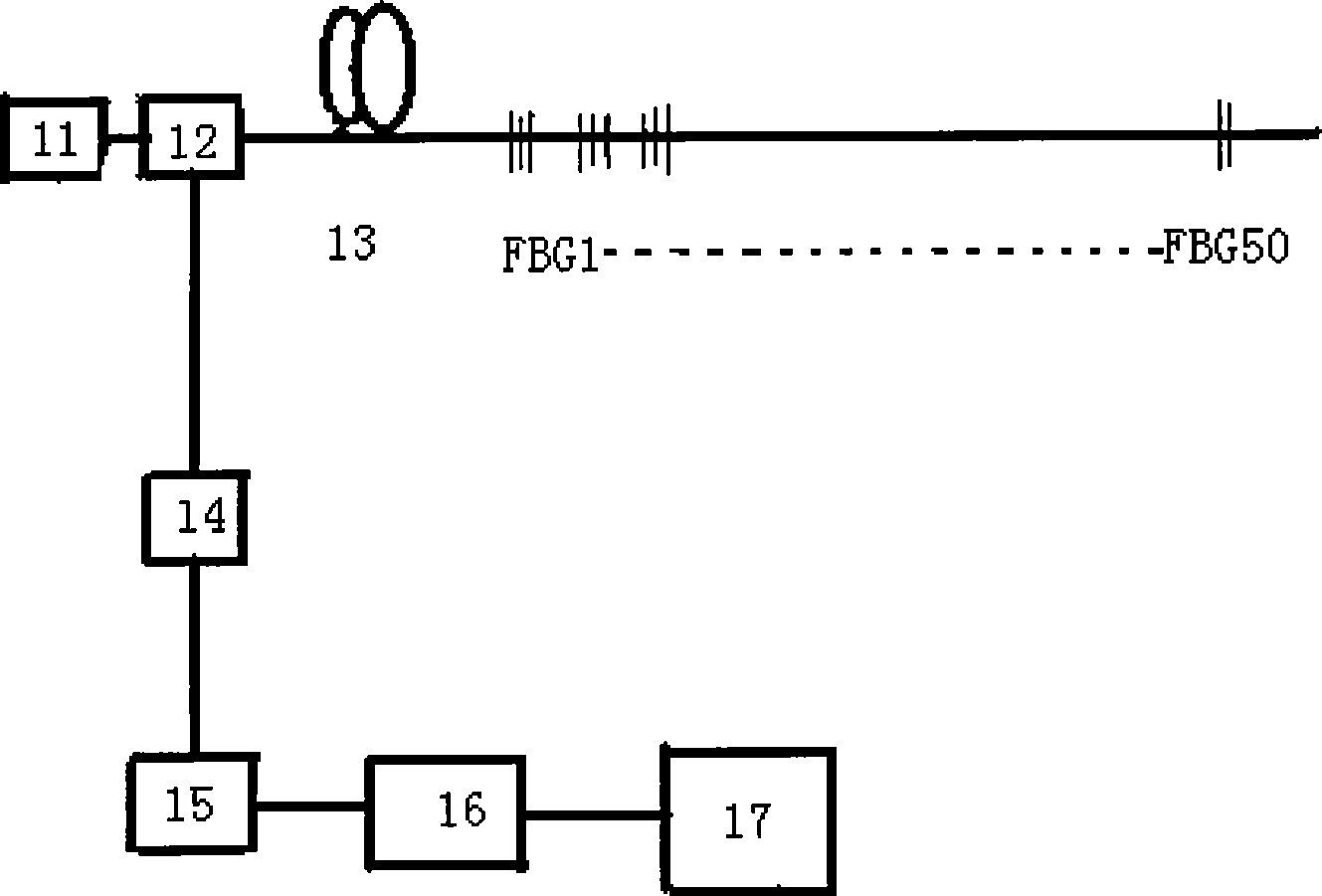

[0012] With reference to Fig. 1, on-line real-time fiber grating fire monitoring system of the present invention comprises laser diode 11, optical fiber circulator 12 with pigtail, temperature-sensitive optical cable 13, optical fiber coarse wavelength division multiplexing demodulator 14, photodetector 15, digital Signal processor 16 and display or alarm 17, the input end of optical fiber circulator 12 links to each other with the laser diode 11 of band pigtail, and a port of optical fiber circulator 12 links to each other with one end of temperature-sensitive optical cable 13, on temperature-sensitive optical cable 13 It is connected with n fiber grating temperature-sensitive fire detectors (18) of the same wavelength, n is a positive integer, the backscattered light and reflected light generated by the temperature-sensitive optical cable 13 enter through the fiber optic circulator 12, and the fiber grating sensor caused by temperature changes The main wavelength displacement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com