Method for measuring composition of brake tube for railway vehicle

A measurement method and railway vehicle technology, applied in the direction of measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of difficult positioning, low measurement efficiency and measurement accuracy, complicated operation, etc., and achieve simple operation, high measurement accuracy and measurement efficiency , the effect of a reasonable measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

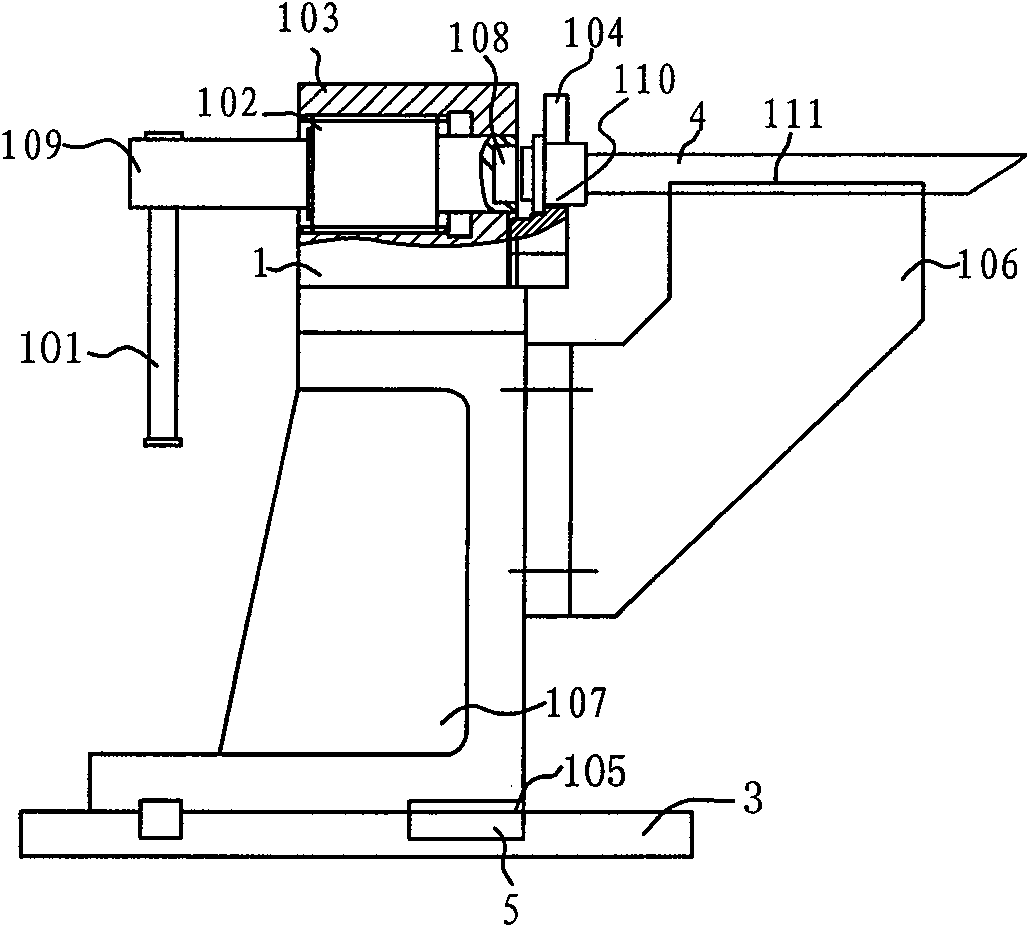

[0033] Referring to Fig. 1 , the screw rod moving measuring head 102 of the moving measuring head 1 used in the present invention is provided with a nut 103 matched by thread, the nut 103 is fixed on the connecting seat 107 of the moving measuring head, and the bottom of the connecting seat 107 of the moving measuring head is provided with The movable head positioning key 105 that can cooperate with the chute 5 on the working platform 3 in clearance. The screw moving measuring head 102 is composed of a screw rod 109 and a sleeve type calliper 108 arranged at the front end of the screw rod 109. An operating handle 101 for easy manipulation can be arranged on the screw rod moving measuring head 102. The inner measuring shape of the sleeve type calliper 108 is consistent with the The shape of the pipe joint ends of the brake pipe composition 4 is corresponding. The outer end of the screw moving measuring head 102 is provided with a pipe joint first positioning seat 104 which has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com