Unidirectional double-layer cable curtain wall

A curtain wall, double-layer technology, applied in the field of simplified cable-structured glass curtain wall, can solve the problems of large deformation of the cable net structure, affecting the normal use, insufficient strength of the steel cable, etc. , ideal architectural effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

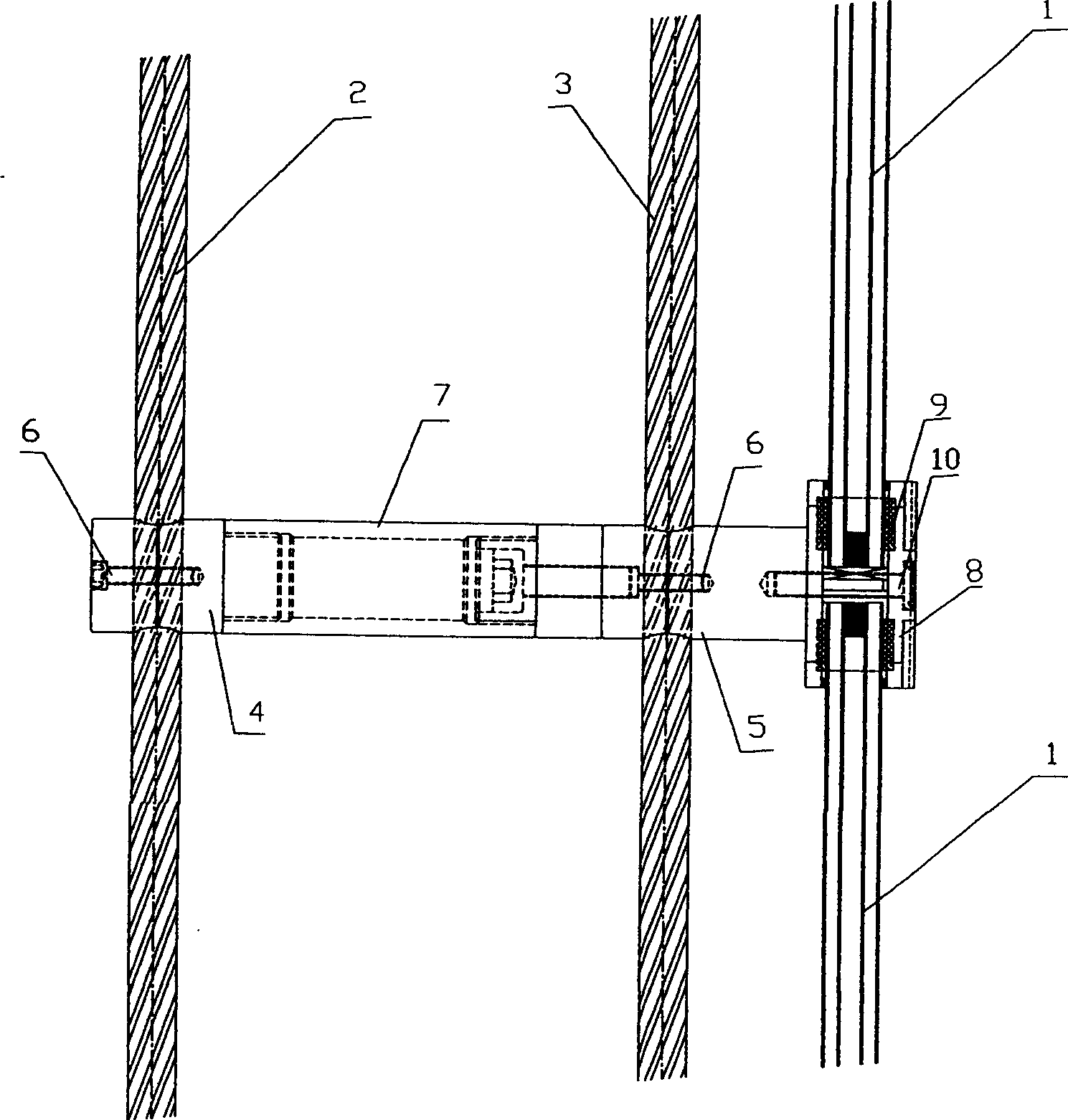

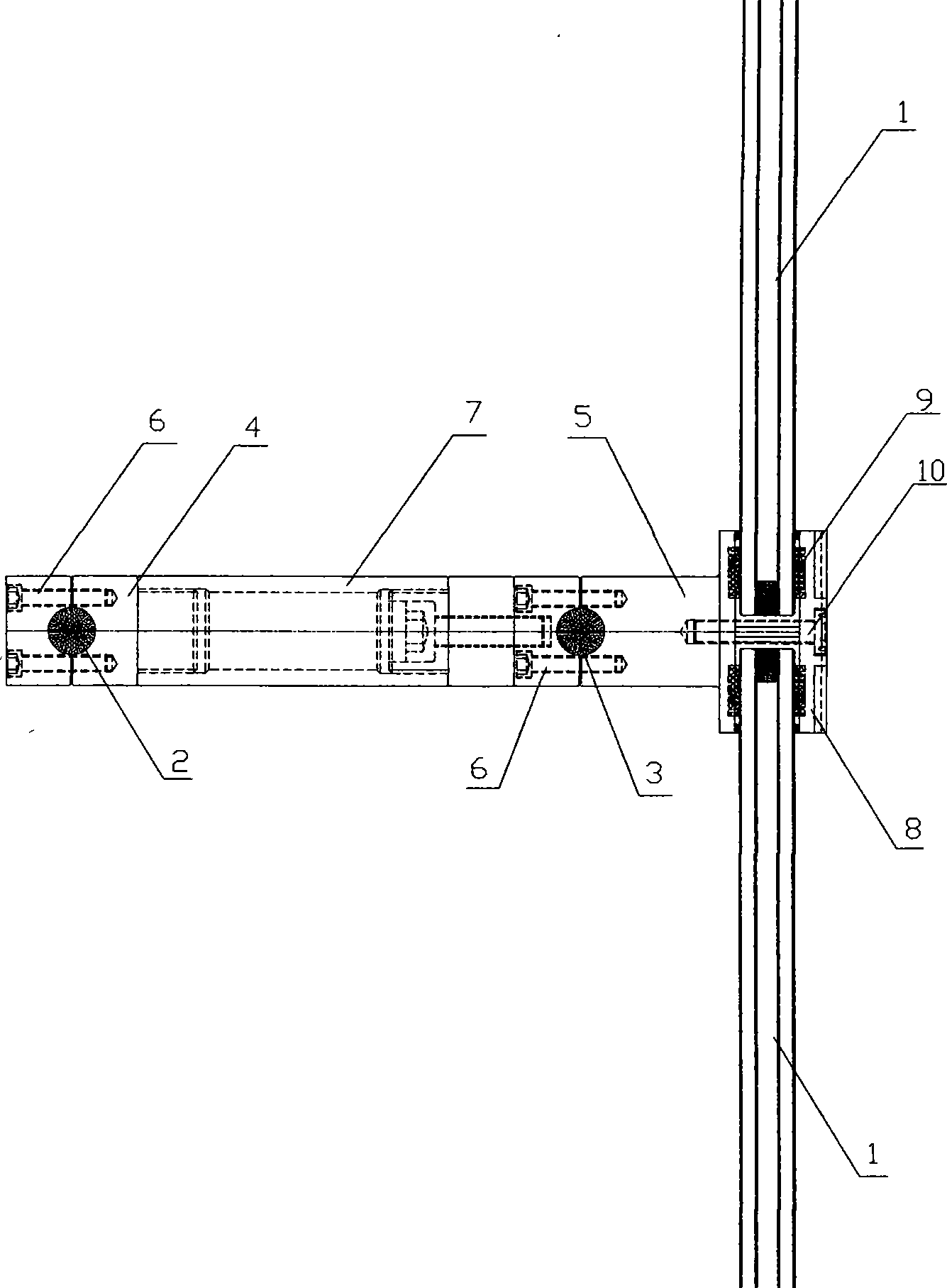

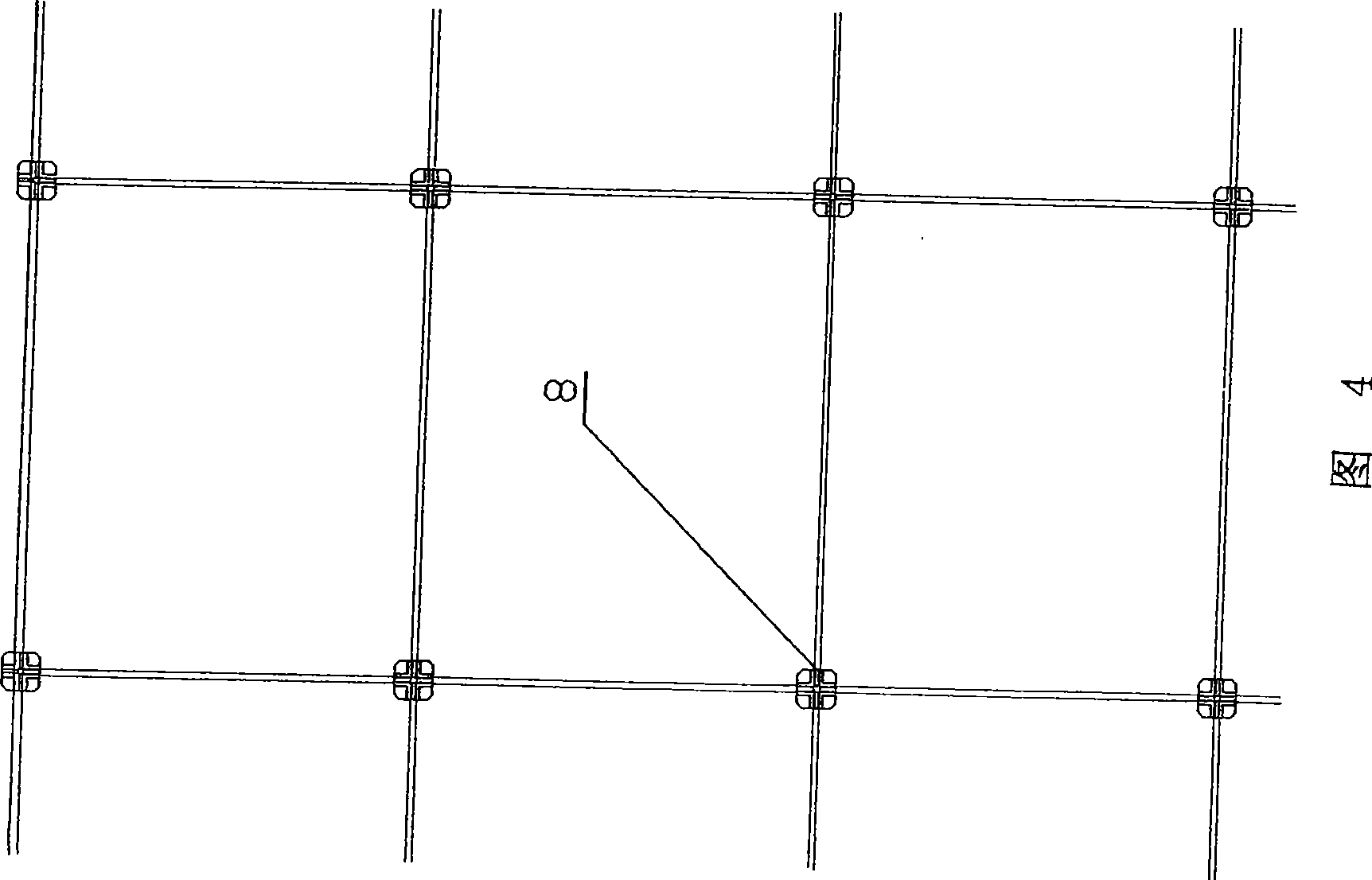

[0012] refer to figure 1 with figure 2 , the present invention adopts a unidirectional double-layer cable curtain wall: on the inside or outside of the glass curtain wall composed of glass panels 1, a group of longitudinal steel cables tensioned from top to bottom are arranged along the horizontal direction of the curtain wall, The longitudinal steel stay cables can be stainless steel stay cables, and each set of steel stay cables includes an outer steel stay cable 2 and an inner steel stay cable 3 . The two ends of the outer steel cable 2 and the inner steel cable 3 are respectively fixed on the upper and lower fixed structures. The fixed structure is a truss or a steel frame or a concrete structure or a main building structure or a ground embedded part (a general basic equipment for a curtain wall building, located in figure 1 The upper and lower positions in the middle are not drawn in the figure). The geometric plane formed between the outer steel cables 2 and the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com