Tube-type ozone generator

An ozone generator and tube-type technology, applied in the field of tube-type ozone generators, can solve the problems of unreasonable connection structure, poor discharge effect, short service life, etc., and achieve the effects of improved anti-seismic ability, guaranteed performance and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

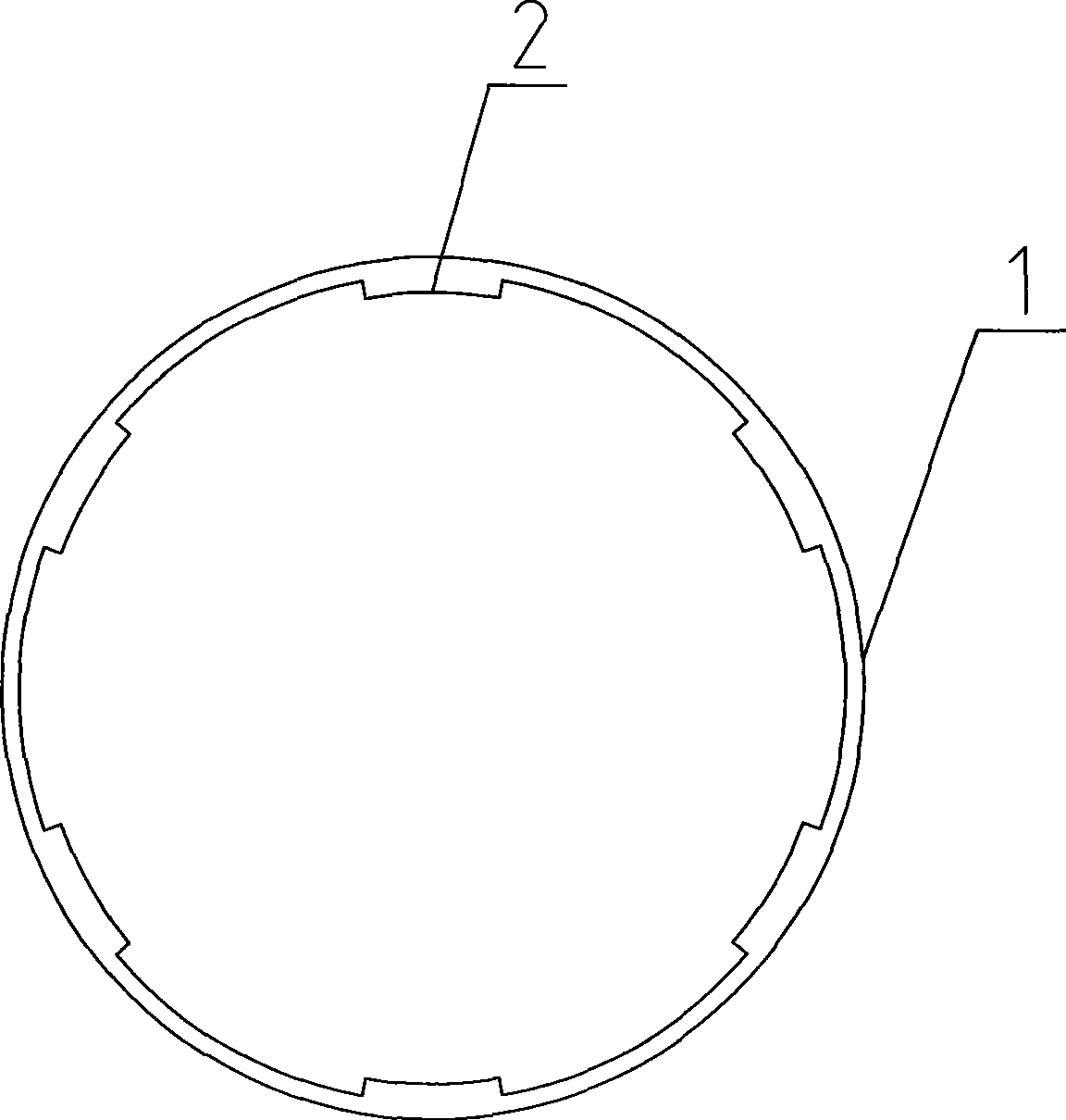

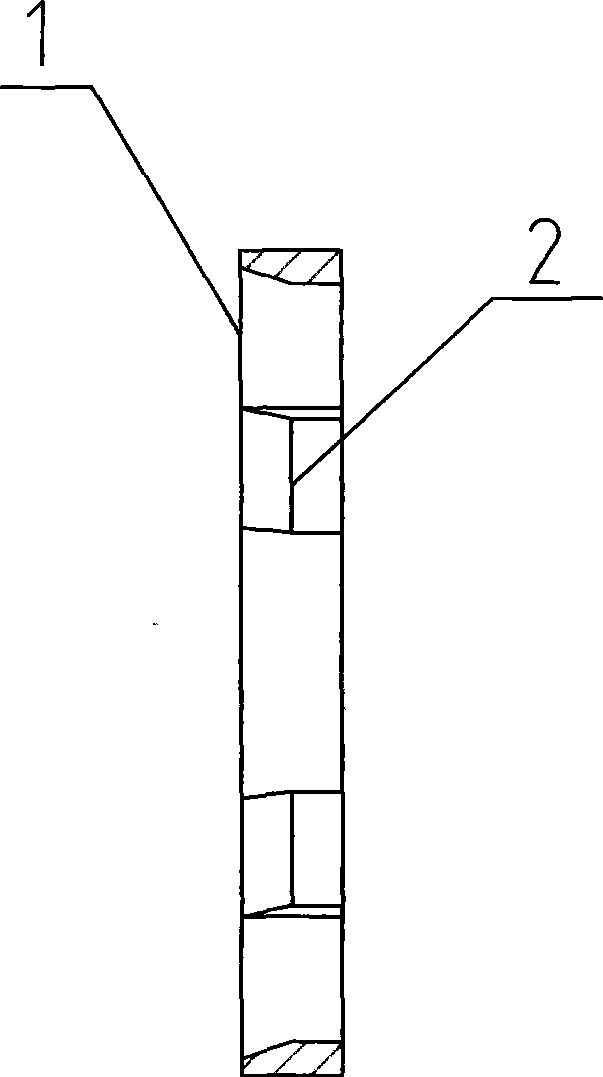

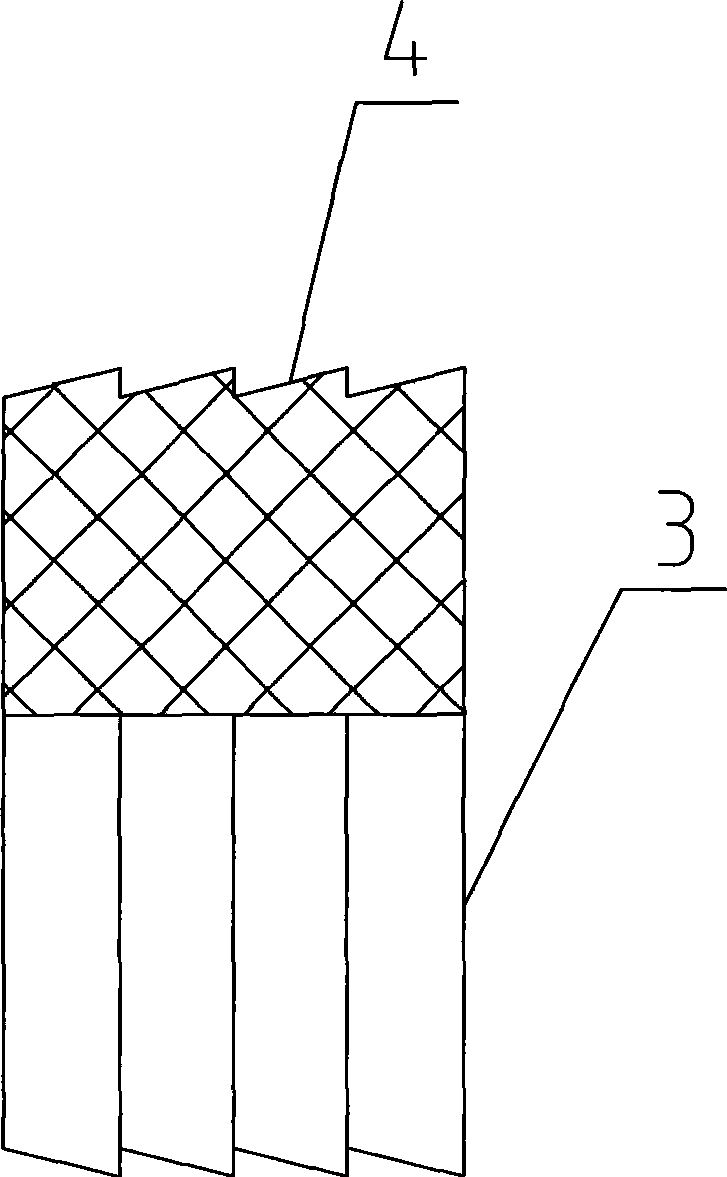

[0013] Such as Figure 1 to Figure 4 The specific embodiment of the present invention shown is a tubular structure ozone generator, comprising a metal outer tube 6 and a glass inner tube 5, a six-sided support is arranged between the metal outer tube 6 and the glass inner tube 5 Ring 1, the inner surface of the six-sided support ring 1 is provided with six contacts 2, and the contacts 2 are in contact with the glass inner tube 5. Both ends of the glass inner tube 5 are provided with sealing plugs 3 . The end of the sealing plug 3 is a structure of three truncated cones 4 arranged vertically, and the sharp edge of the truncated cones 4 is chamfered and the fillet radius is ≤0.2. In addition, the six-sided support ring 1 and the sealing plug 3 are made of ozone-resistant silicon rubber.

[0014] When installing, first install the sealing plug 3 on both sides of the inner glass tube 5, then heat the glass tube to discharge the air in the glass tube, and then set the six-sided s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com