Gloves demolding technique

A demoulding and glove technology, applied in gloves, clothing, clothing, etc., can solve the problems of uneven surface of gloves and easy mixing of gloves, and achieve the effect of saving demoulding space, prolonging cooling time, and saving use cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

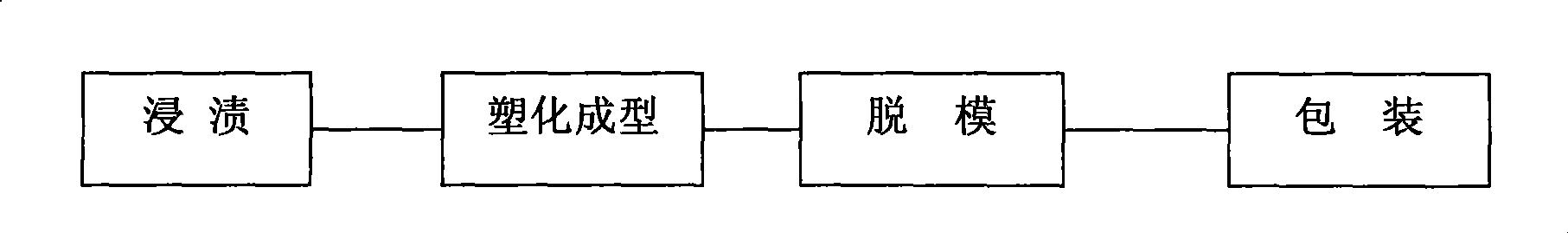

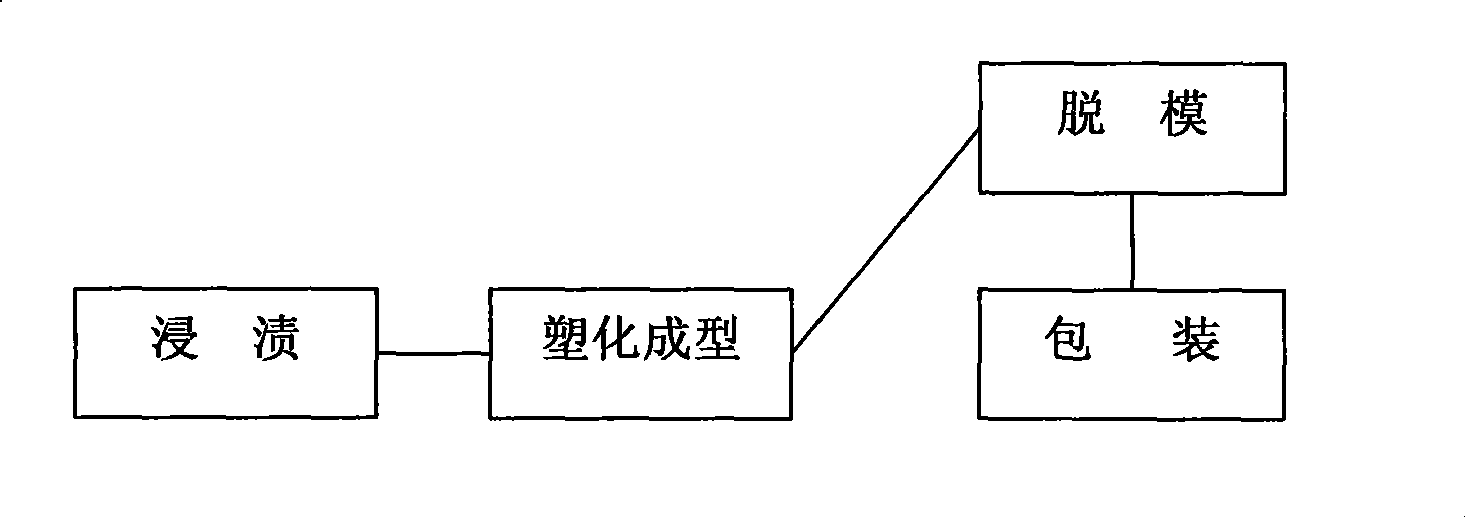

[0013] figure 2 It is the best embodiment of the present invention. Production line process such as figure 2 Shown, impregnation, plastic molding, demoulding, packaging.

[0014] Such as figure 2 As shown, the design length of the entire glove production line is 128 meters. The original production line process impregnation, plasticization, demoulding, and packaging are all on one floor. Now the demoulding area of the one-story production line is moved up 3 meters through a 45-degree slope Establish a demoulding area on the second floor. The demoulding area is designed to be 9 meters long and 2 meters high. The demoulding area on the second floor and the packaging area on the first floor are designed in a vertical plane. The production lines on the second floor and the first floor are separated by floors. The gloves on the lower floor pass through the openings set on the floors, and the blanking barrels passing through the openings fall directly onto the packaging table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com