Permanent magnetic synchronous motor having single electricity port and dual mechanical port of same speed in reversed direction

A permanent magnet synchronous motor, dual-machine technology, applied in electrical components, electromechanical devices, etc., can solve the problems of reduced motor reliability, mechanical volume, weight, maintenance difficulty and cost increase, etc., to improve reliability and improve operating efficiency. , the effect of high torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The motor of the present invention will be described in further detail below in conjunction with the accompanying drawings.

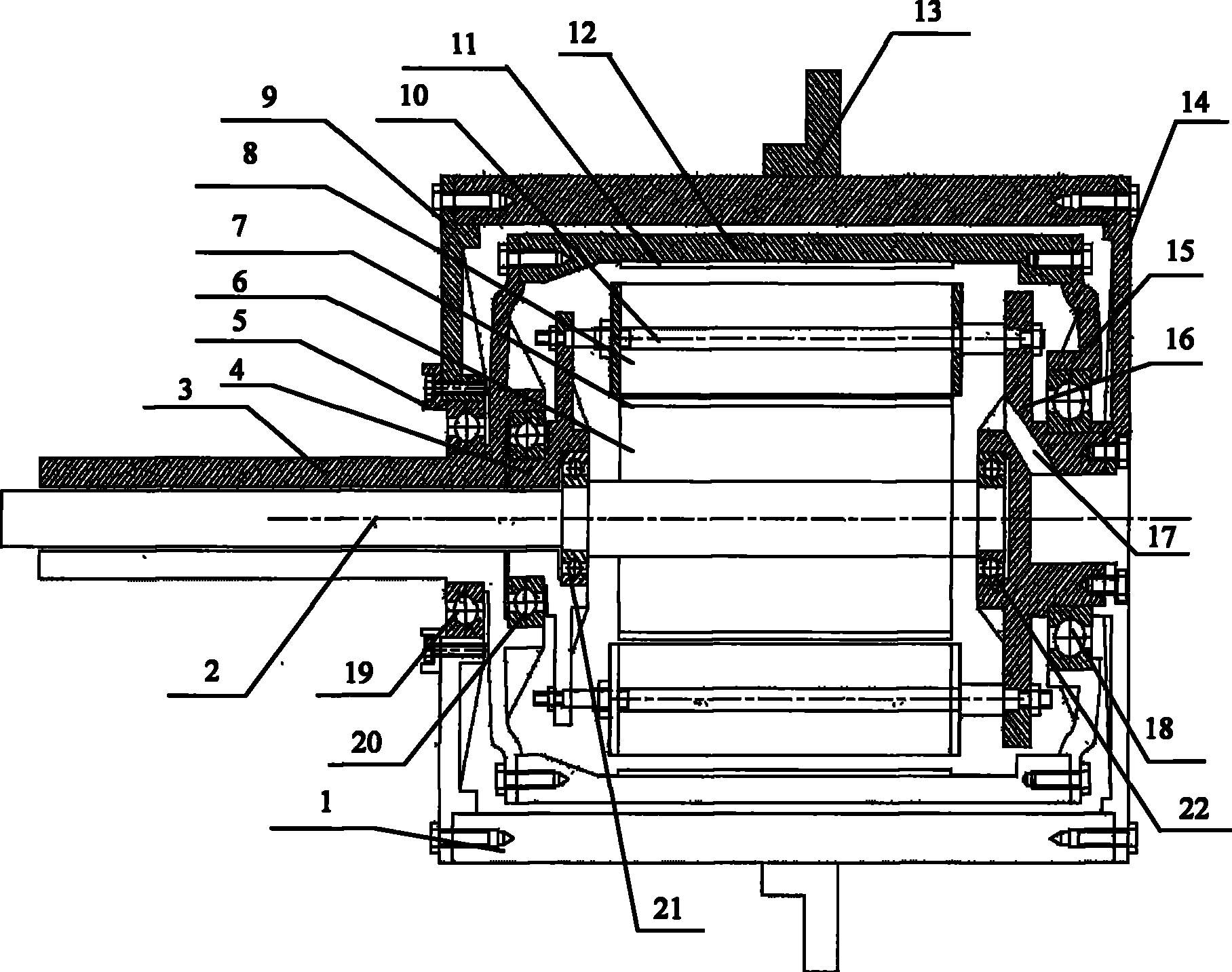

[0019] Such as figure 1 As shown in the schematic diagram of the motor structure of the present invention, the solid shaft 2 and the hollow shaft 3 are concentric, and the left end of the solid shaft 2 is sequentially assembled with the inner shaft front bearing 21, the stator front end cover 4, the outer shaft front bearing 20, and the hollow shaft 3 from the inside to the outside. The casing bearing 19, the casing bearing front end cover 5, the right end of the solid shaft 2 are installed sequentially from the inside to the outside as the inner shaft rear bearing 22, the stator rear end cover 16, the outer shaft rear bearing 18, the outer rotor rear end cover 15, and the casing rear The end cover 14, the middle part of the solid shaft is assembled with the inner permanent magnet rotor 6, the stator 8, the outer permanent magnet rotor 12 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com