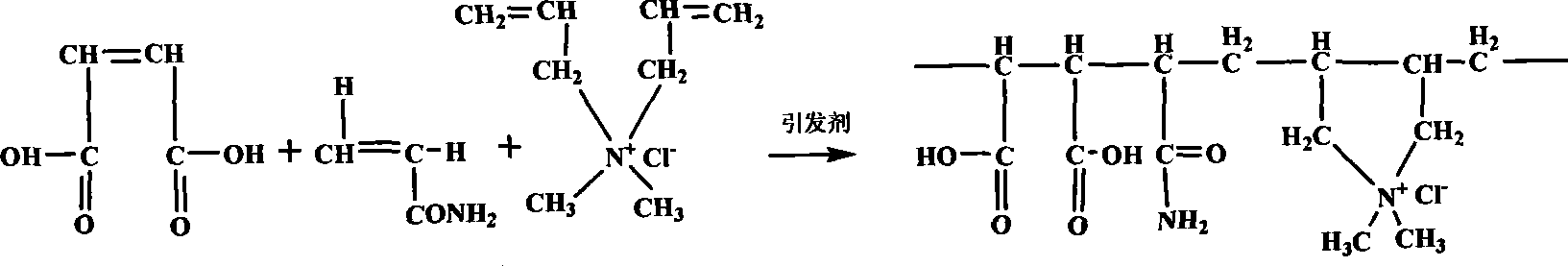

Method for preparing nano amphoteric polyacrylamide additives

A polyacrylamide and amphoteric technology, applied in the field of polymer chemical synthesis, can solve the problems of physical properties and structural damage, poor strength, difficult water filtration, etc., and achieve easy continuous industrial production, controllable particle size, and simple experimental equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

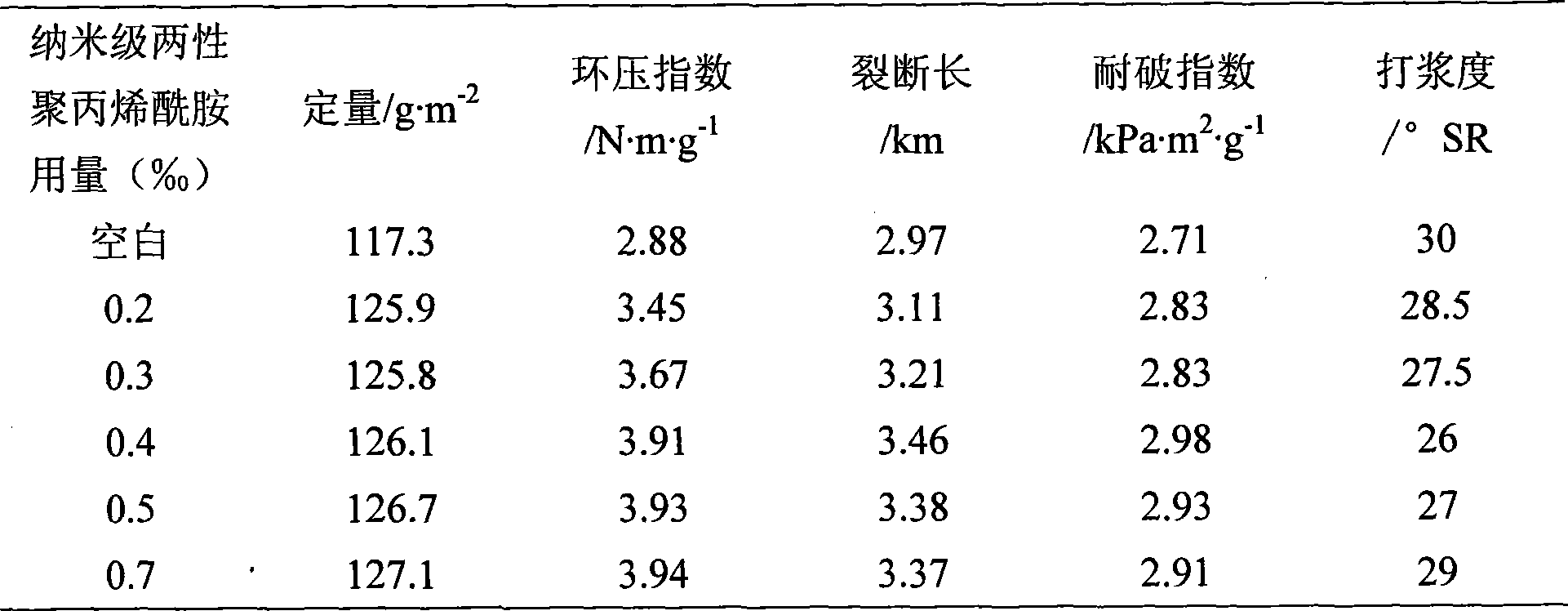

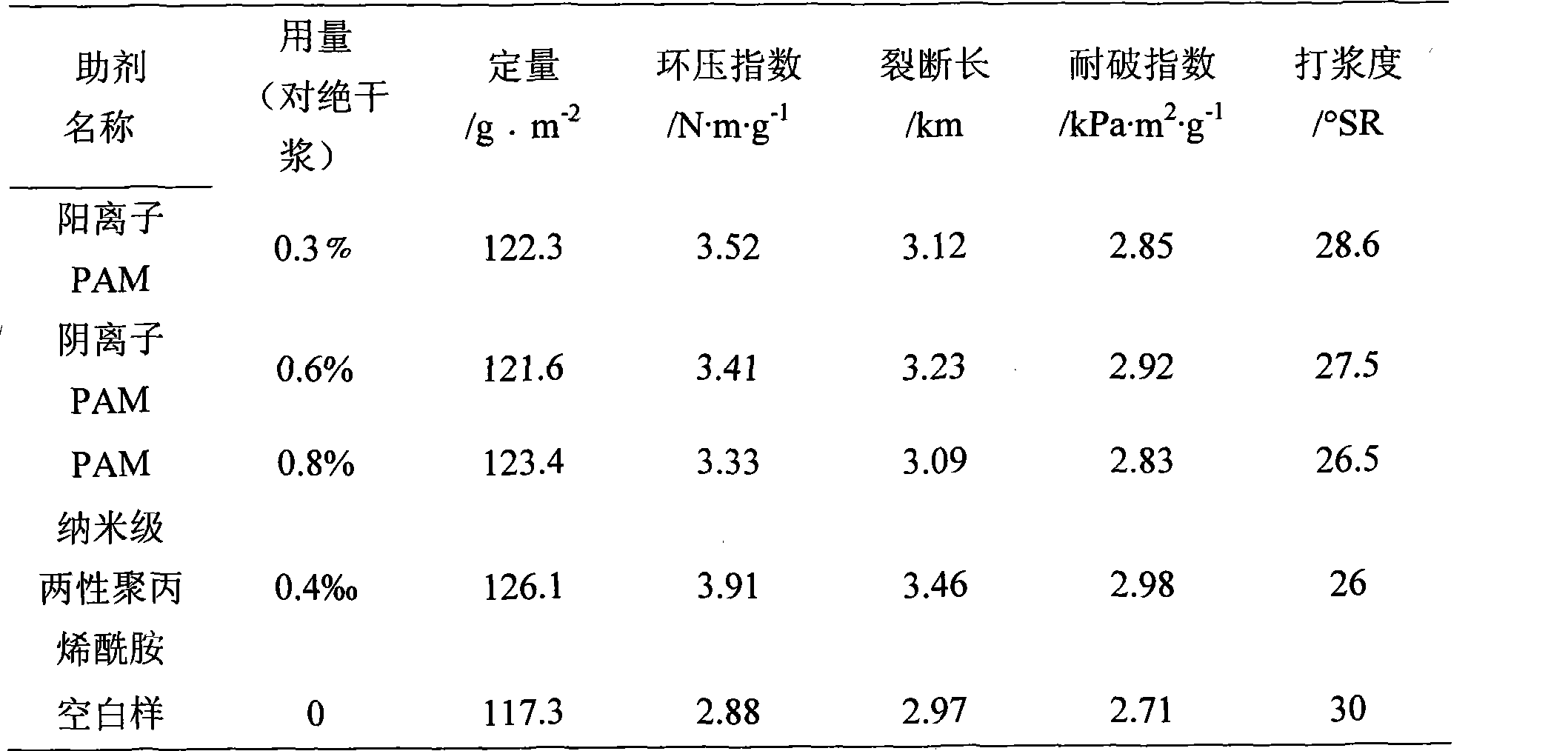

Examples

Embodiment 1

[0025] AM, MA and DMDAAC three kinds of monomers are AM according to molar ratio in beaker: MA: DMDAAC=50:30:20, be configured into 100g aqueous solution, concentration is 50% quality, adjust pH value to 6.0 with ammonia water, and in Add 1.5 g of reducing agent sodium bisulfite to the aqueous solution.

[0026] In a four-necked flask equipped with a stirrer, a reflux condenser, a nitrogen pipe and a thermometer, add a composite emulsifier composed of 16g Span80 and 24gTween60, 6.7g n-butanol and 200g isooctane, and the stirring speed is 150r / min, stirring and emulsifying 30min, while passing nitrogen.

[0027] Add the solution in the beaker dropwise to the four-necked flask within 20 minutes, heat it to the reaction temperature of 50°C, add 1.5 g of the oxidant potassium persulfate dropwise to the four-necked flask at a controlled time of 30 minutes, and 2 Polymerization was initiated under the protection of , sealed and reacted for 3h, and 8g of anhydrous sodium acetate w...

Embodiment 2

[0030] AM, MA and DMDAAC three kinds of monomers are AM according to molar ratio in beaker: MA: DMDAAC=50:30:20, be configured into 100g aqueous solution, concentration is 55% quality, adjust pH value to 7.0 with ammonia water, and in Add 2g of reducing agent sodium bisulfite to the aqueous solution.

[0031] Add the compound emulsifier that 22.5g Span80 and 52.5g Tween60 make up, 10.7g n-butanol and 300 isooctane in the four-necked flask that agitator, reflux condenser, nitrogen pipe and thermometer are equipped, stirring speed is 300r / min , stirred and emulsified for 20 minutes, and nitrogen gas was introduced at the same time.

[0032]Add the solution in the beaker dropwise to the four-neck flask for a controlled time of 15 minutes, continue to stir and feed in N 2 , heated to a reaction temperature of 40°C, and added dropwise 2g of oxidant potassium persulfate to a four-neck flask for 25 minutes under control, and 2 Polymerization was initiated under the protection of , ...

Embodiment 3

[0035] AM, MA and DMDAAC three kinds of monomers are AM according to molar ratio in beaker: MA: DMDAAC=50:30:20, be configured into 100g aqueous solution, concentration is 55% quality, adjust pH value to 7.0 with ammonia water, and in Add 3g of reducing agent sodium bisulfite to the aqueous solution.

[0036] Add a compound emulsifier composed of 15g Span80 and 15gTween60, 6g n-butanol and 100 isooctane into a four-necked flask equipped with a stirrer, a reflux condenser, a nitrogen pipe and a thermometer, and stir and emulsify for 25min at a stirring speed of 200r / min , while feeding nitrogen.

[0037] Add the solution in the beaker dropwise to the four-neck flask for a controlled time of 25 minutes, continue to stir and feed in N 2 , heated to a reaction temperature of 60°C, and added dropwise 3g of oxidant potassium persulfate into a four-neck flask for 35min under control, and 2 Polymerization was initiated under the protection of , sealed and reacted for 4h, and 3g of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com