Liquid crystal display panel and method for producing the same

A liquid crystal display panel, liquid crystal layer technology, applied in liquid crystal materials, chemical instruments and methods, optics and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

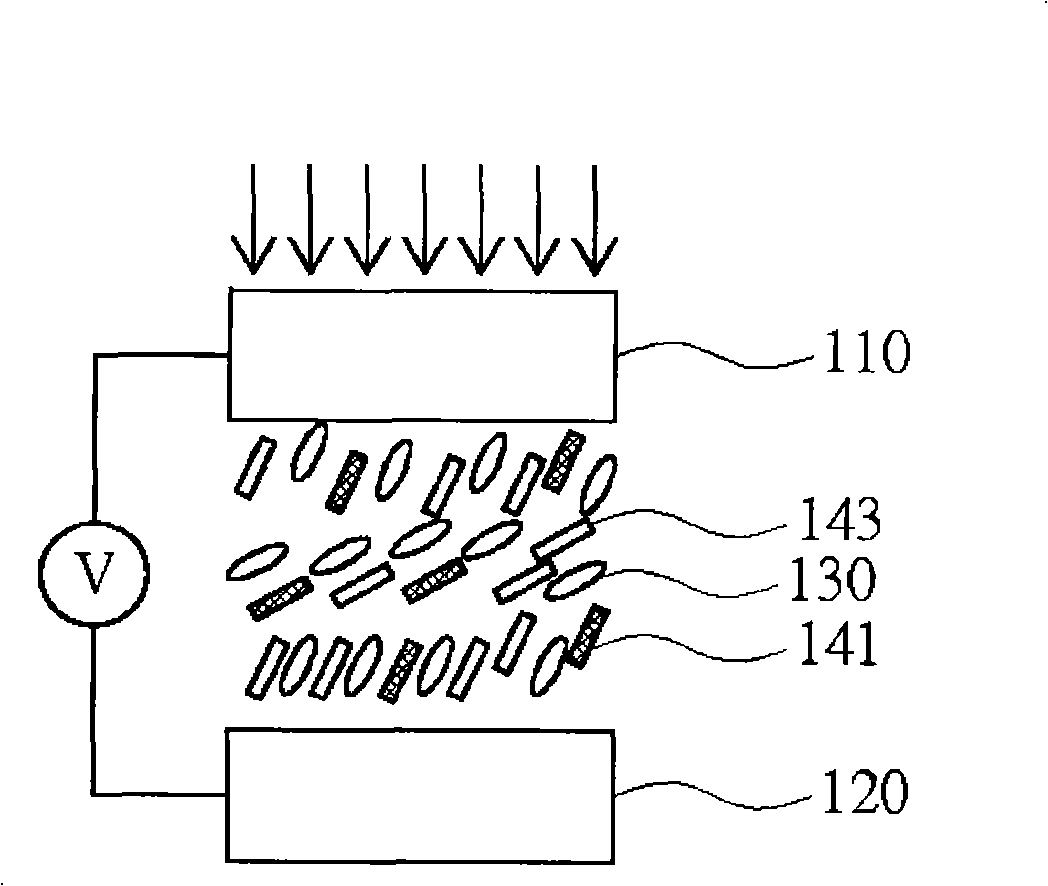

[0019] According to the applicant's preliminary experimental results, the higher the residual amount of photosensitive monomer in the liquid crystal display panel, the more serious the problem of uneven brightness or image retention will be. Accordingly, the applicant believes that the main reason for the uneven brightness of the liquid crystal display panel or image sticking is that the photosensitive monomers in the liquid crystal display panel are not fully polymerized into alignment polymers, and impurities (i.e. photosensitive monomers) are filled in the liquid crystal. The material has a negative impact on the liquid crystal molecular reaction characteristics. Therefore, the present invention mainly proposes a method for manufacturing a liquid crystal display panel, which performs two polymerization reactions, so that the photosensitive monomer can be completely polymerized into an alignment polymer, avoiding residues in the liquid crystal material, and improving uneven b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Absorption wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com