Method for testing fluorescent powder coated film characteristic by tricolor lamp

A characteristic testing, phosphor technology, applied in the direction of fluorescence/phosphorescence, material excitation analysis, etc., to achieve the effect of eliminating hidden dangers and improving the quality of the factory products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

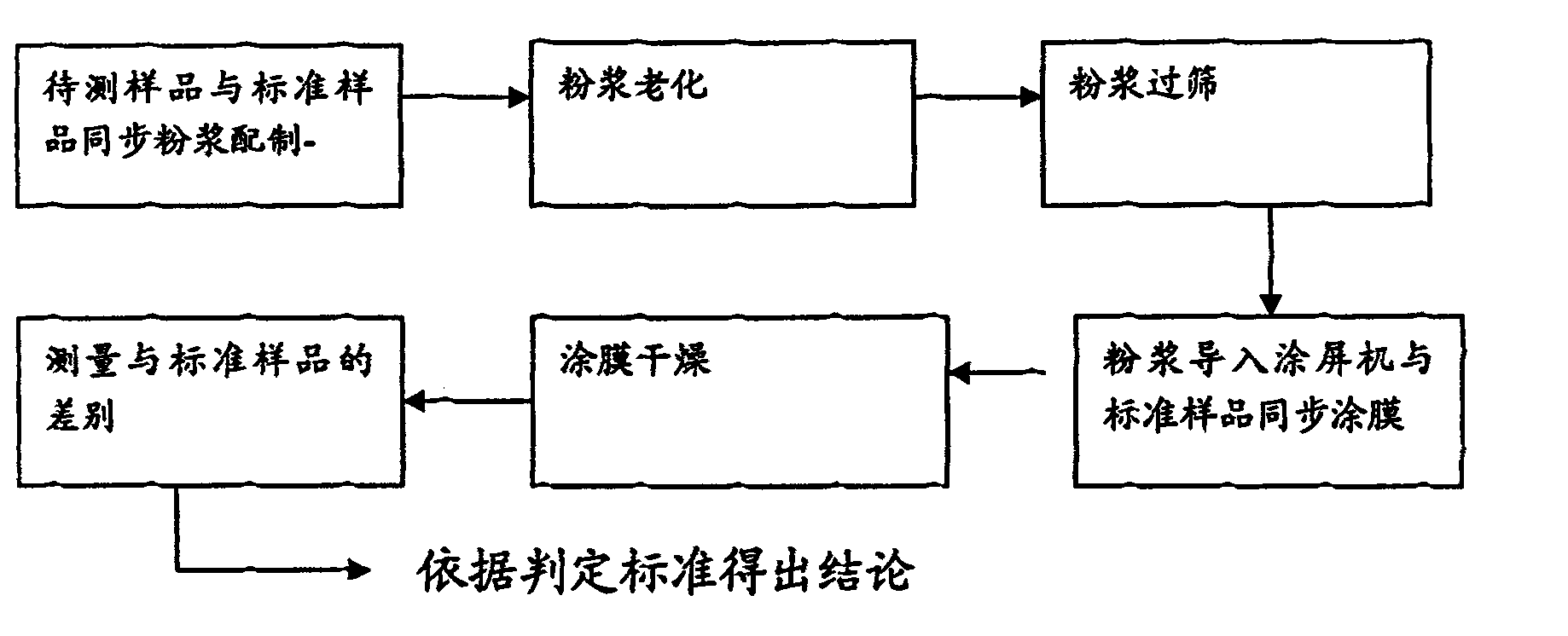

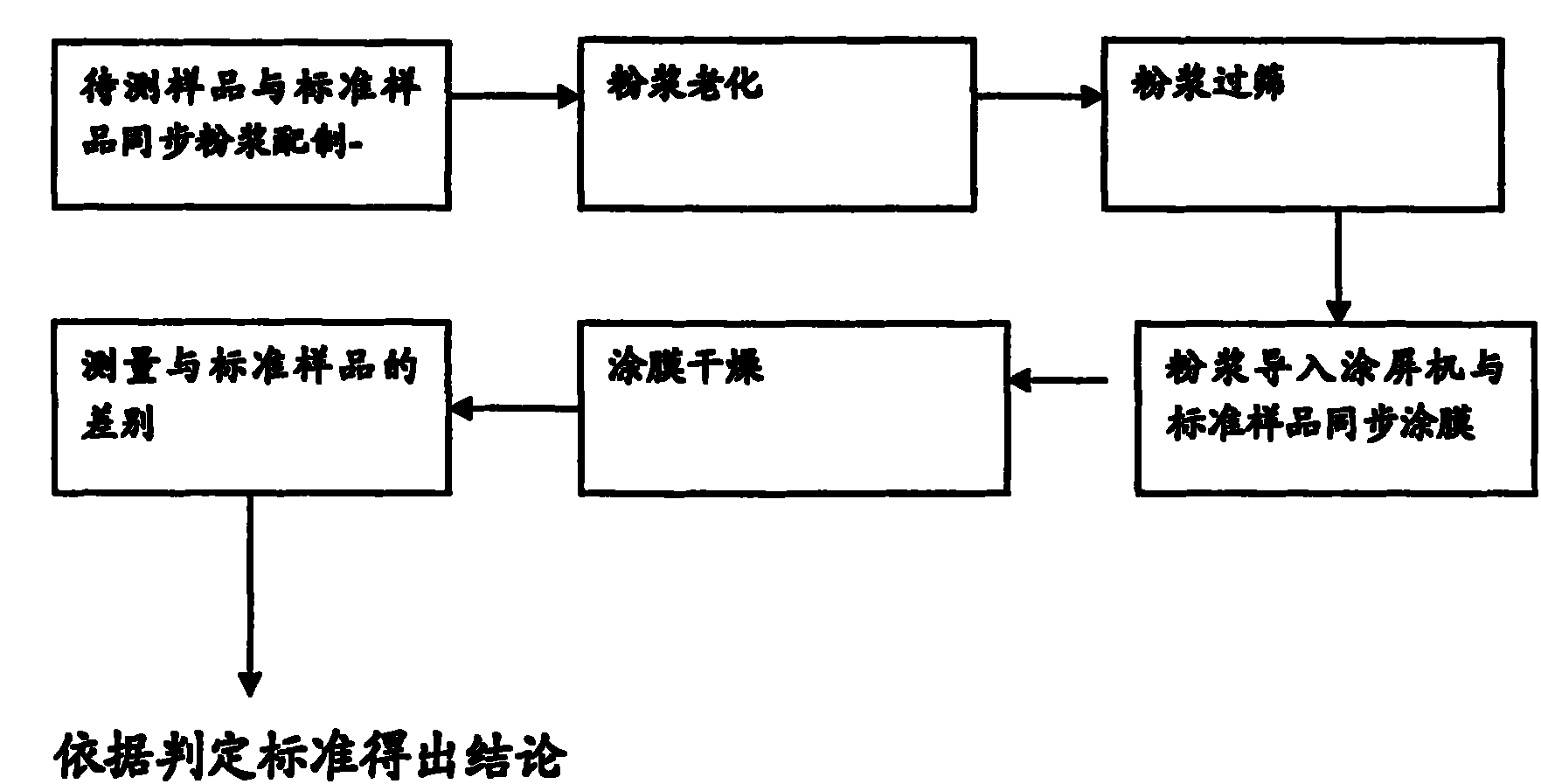

Method used

Image

Examples

Embodiment 1

[0024] First, select the phosphor powder that meets the quality standards as the standard phosphor powder for comparison with the phosphor powder to be tested, and then prepare the powder slurry to be tested and the standard powder slurry respectively according to the following steps:

[0025] Mix 13g of the fluorescent powder sample to be tested, 55g of pure water and 20g of PVA (8.5% concentration), and then add 0.5ml of dispersant (1% polypropylene glycol TW-20) and 0.5ml of defoamer (1% Pluronic L-92), stir evenly to make the slurry to be tested;

[0026] The standard fluorescent powder sample of 13g, the pure water of 55g and the PVA (concentration is 8.5%) of 20g are mixed, then add the dispersant of 0.5ml (1% polypropylene glycol TW-20) and the defoamer of 0.5ml ( 1% Pluronic L-92), stir evenly to make a standard slurry;

[0027] Put the prepared slurry to be tested and the standard slurry prepared above into a 400ml bottle roller machine respectively, control the rota...

Embodiment 2

[0031] First, select the phosphor powder that meets the quality standards as the standard phosphor powder for comparison with the phosphor powder to be tested, and then prepare the powder slurry to be tested and the standard powder slurry respectively according to the following steps:

[0032] 25g of the fluorescent powder sample to be tested, 100g of pure water and 30g of PVA (concentration of 8.5%) were mixed, then 1ml of dispersant (1% polypropylene glycol TW-20) and 1ml of defoamer (1ml) were added thereto % Pluronic L-92), stir and make the powder slurry to be tested;

[0033] 25g of standard fluorescent powder samples, 100g of pure water and 30g of PVA (concentration of 8.5%) were mixed, and then 1ml of dispersant (1% polypropylene glycol TW-20) and defoamer (1% Prop Ronic L-92), stir evenly to make a standard slurry;

[0034] Put the prepared slurry to be tested and the standard slurry prepared above into a 500ml bottle roller machine respectively, control the rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com