Bearing failure diagnosis system

A fault diagnosis system and bearing technology, applied in the field of sensors, can solve problems such as lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0097] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

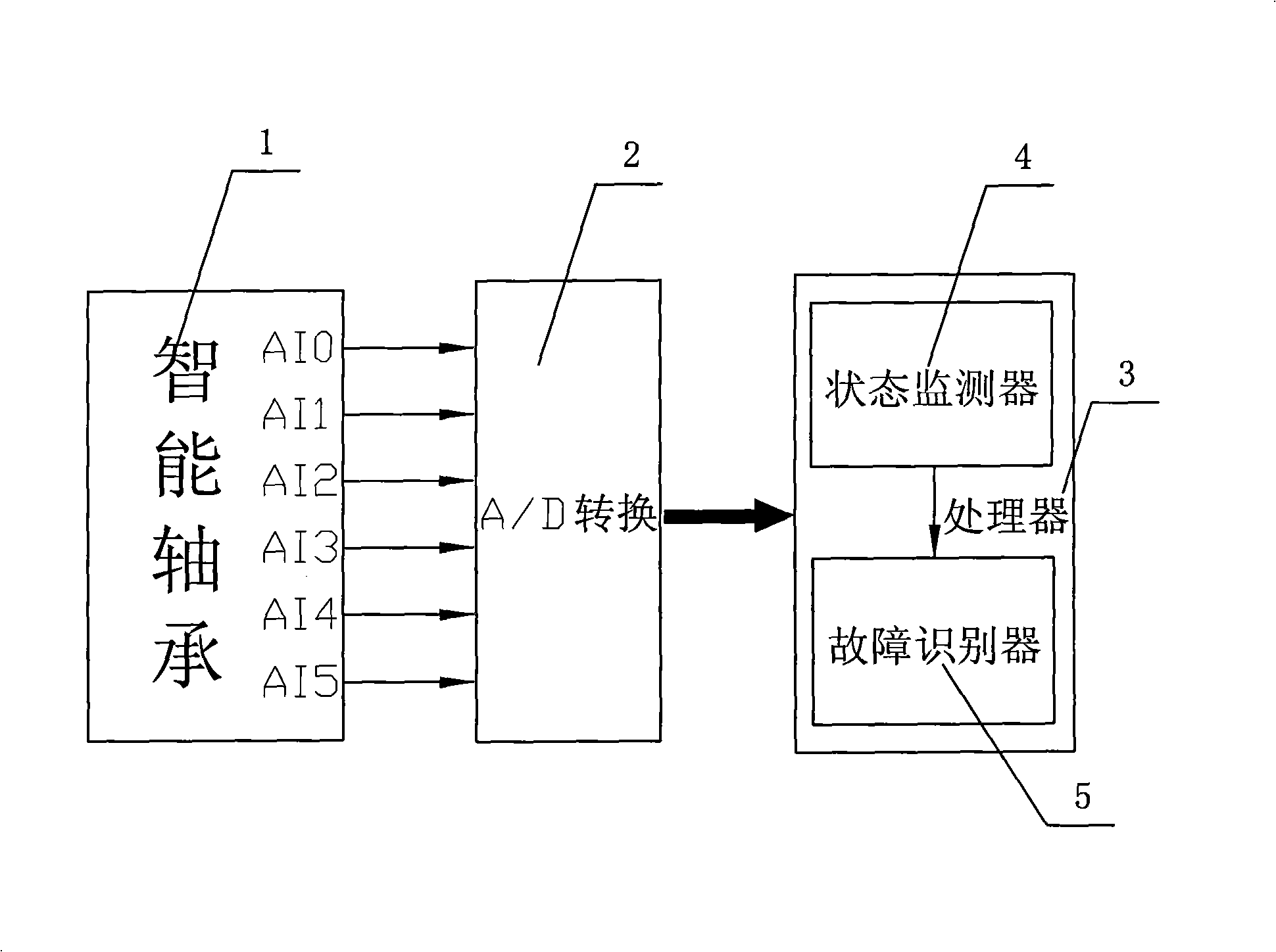

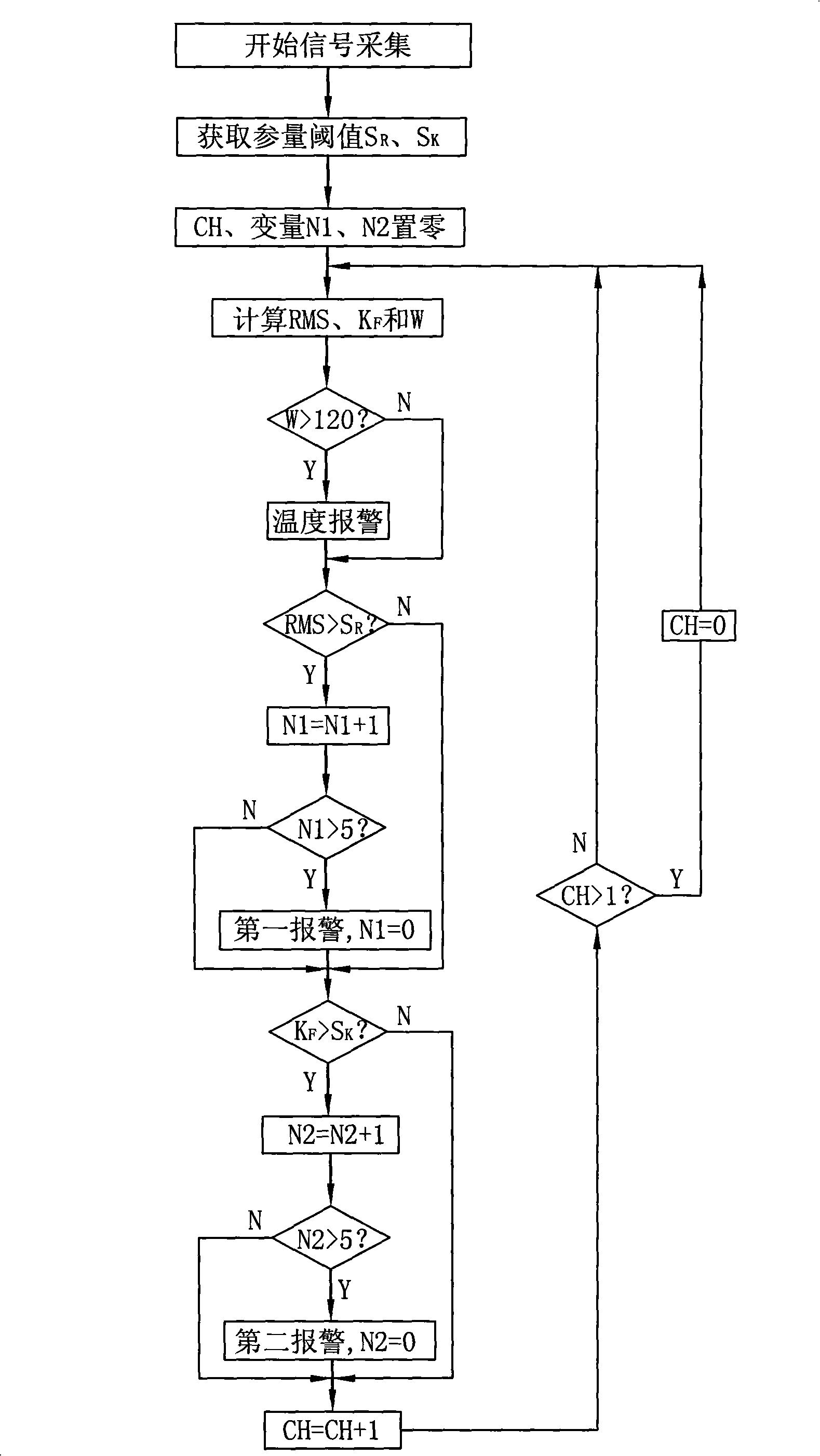

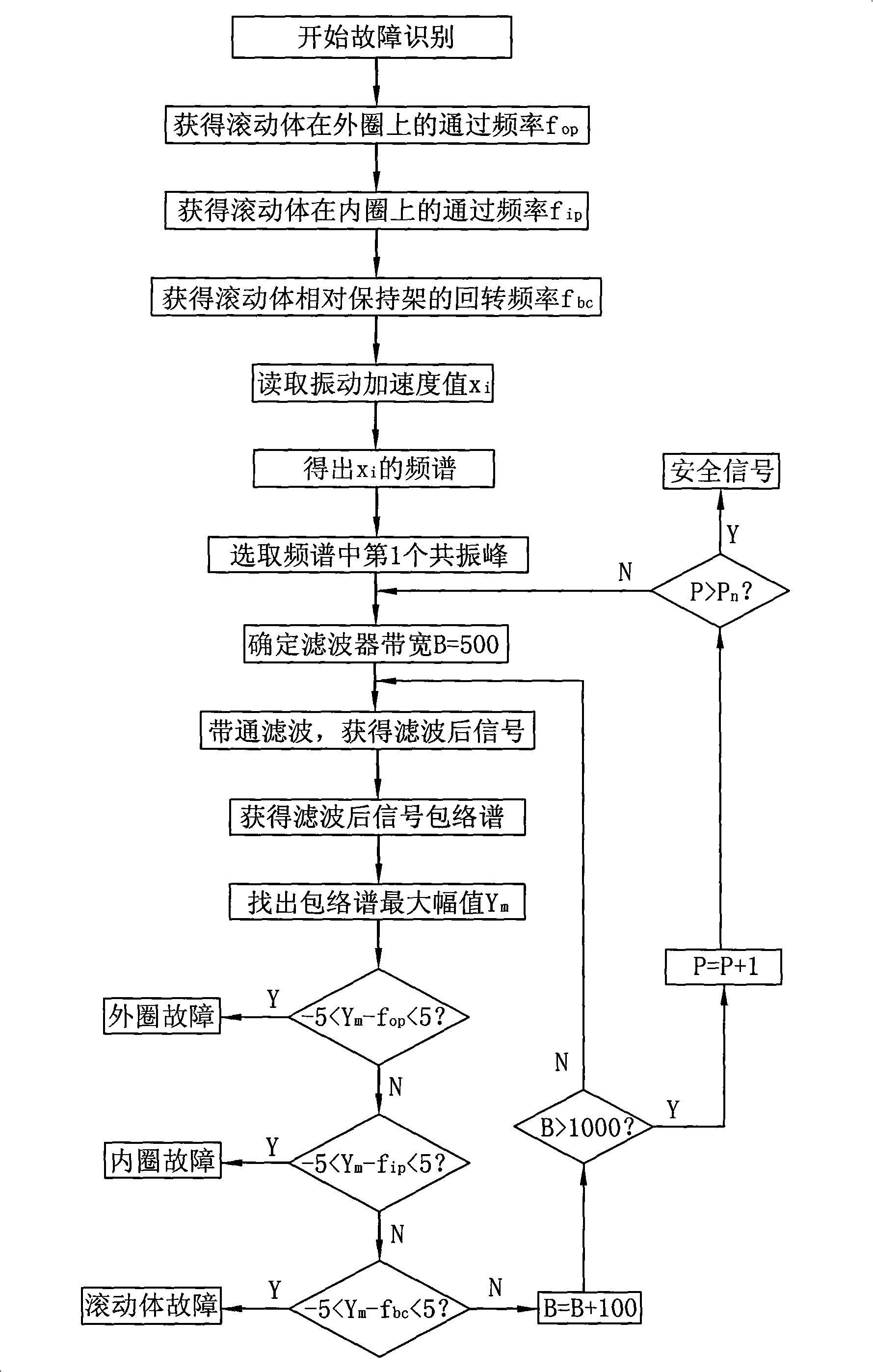

[0098] Such as figure 1As shown, a bearing fault diagnosis system is composed of an intelligent bearing 1, an A / D conversion module 2, a processor, a state monitor and a fault identifier, wherein the intelligent bearing 1 is provided with six output ports, wherein the first and second The output ports AI0 and AI1 each output a set of vibration acceleration signals, the third and fourth output ports AI2 and AI3 each output a set of speed signals, and the fifth and sixth output ports AI4 and AI5 each output a set of temperature signals. The intelligent bearing The six groups of signals output by 1 are sent to the input port of A / D conversion module 2, and the A / D conversion module 2 converts the six groups of signals into digital signals, and the six groups of digital signals output by A / D conversion module 2 are sent to the processor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com