Small electric valve for shock-absorbing protecting torsion force

An electric valve and torque technology, applied in valve details, valve devices, engine components, etc., can solve the problems of actuator damage, equipment or system loss, valve leakage rate, etc., and achieve small opening torque, high pressure bearing characteristics, The effect of high pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

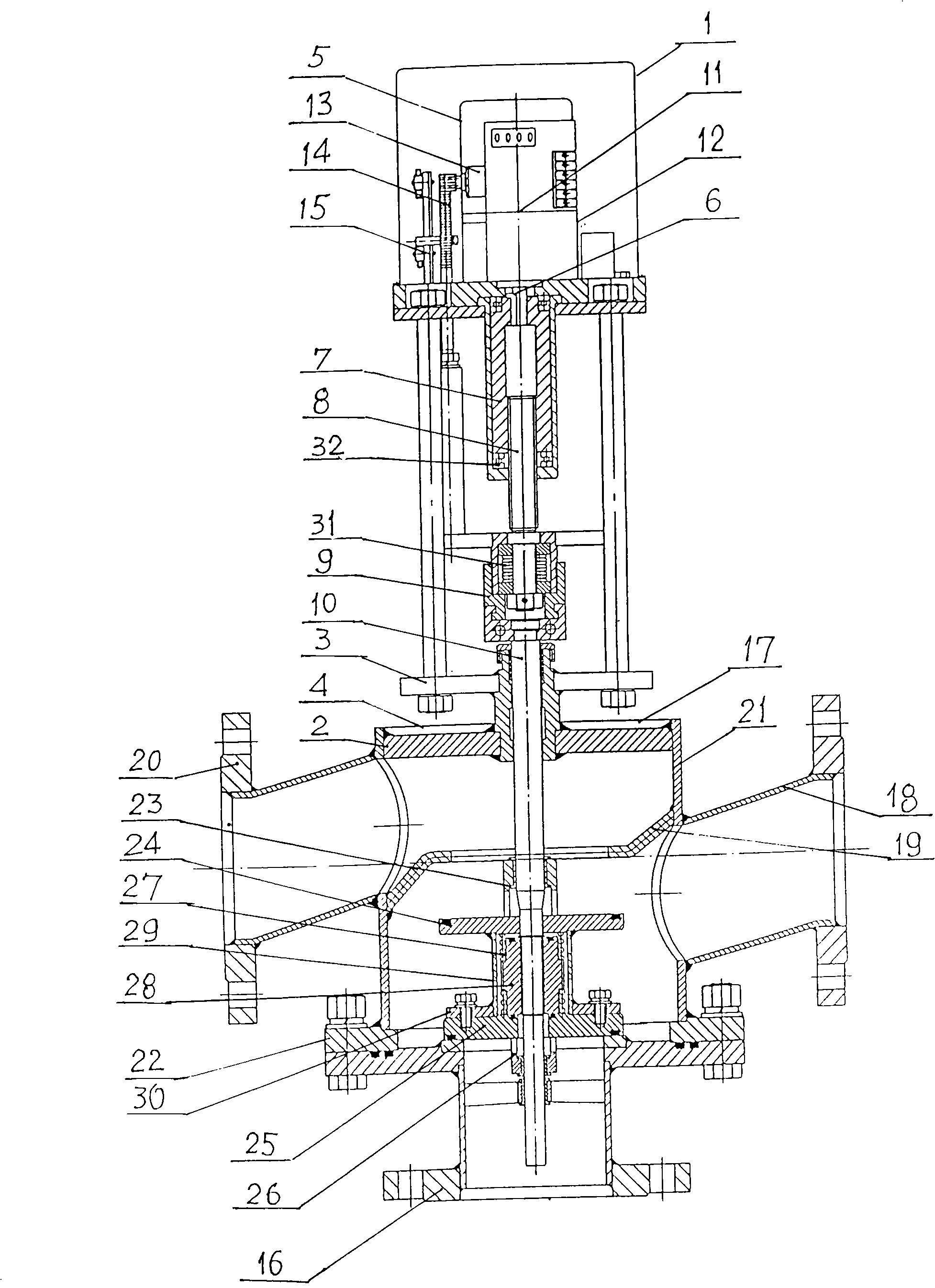

[0017] see figure 1 , the present invention is composed of two parts, the actuator 1 and the valve body 2. The actuator 1 is installed and fixed on the valve seat 4 on the top of the valve body through the lower bracket plate 3. The nut 7 is connected, and the two ends of the transmission nut 7 are equipped with plane thrust ball bearings 32, the torque is greatly reduced, the opening is easy and labor-saving, and the hand can be twisted, while the traditional technology is impossible to twist by hand, and can only be opened by the oil pump. The transmission nut 7 It also cooperates with the transmission screw 8 with a T-shaped thread to change the rotational motion of the driving motor 5 into the up and down movement of the transmission screw 8. The transmission screw is connected to the valve shaft 10 through the coupling 9, and the coupling 9 is equipped with an anti-shock and shock absorber. Belleville spring 31, a position signal feedback device, an analog controller 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com