KL bean vegetable gum type environment-protective slurry and preparation thereof

A technology of bitter bean and plant glue, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., and can solve the problems of high price and insufficient supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] Present embodiment 1 bitter bean plant gum type environmental protection mud, comprises following components:

[0118] Bitter bean vegetable gum 6g

[0119] 0.2 grams of hydrolyzed polyacrylamide with a molecular weight of 12 million

[0121] 1000ml of water.

[0122] The preparation method of the present embodiment 1 bitter bean vegetable gum type environmental protection mud is proportioning ingredients, adding bitter common bean vegetable gum and hydrolyzed polyacrylamide to water at the same time, adding sodium hydroxide after stirring for 30 minutes, and stirring for another 15 minutes, that is Form bitter bean plant glue type environmental protection mud.

[0123] The above-mentioned bitter bean vegetable gum is prepared by the following method:

[0124] 1) Cleaning: remove stones, clods, grass sticks and other impurities in the seeds of the bitter bean plant,

[0125] 2) Embryo extraction: remove the seed coat and cotyledons t...

Embodiment 2

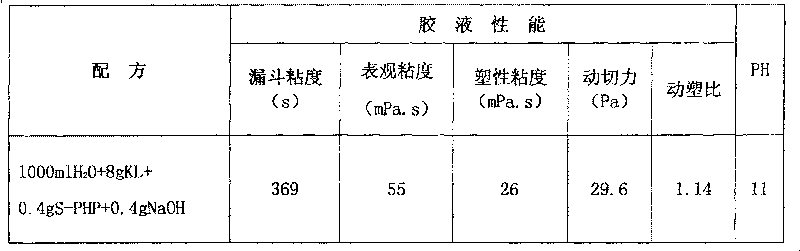

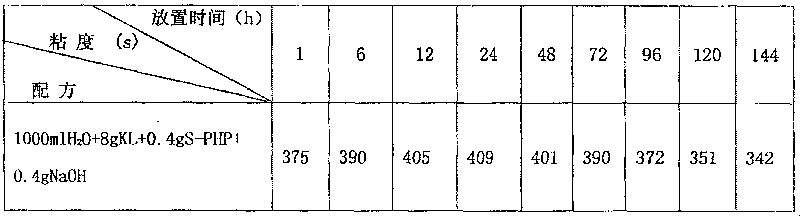

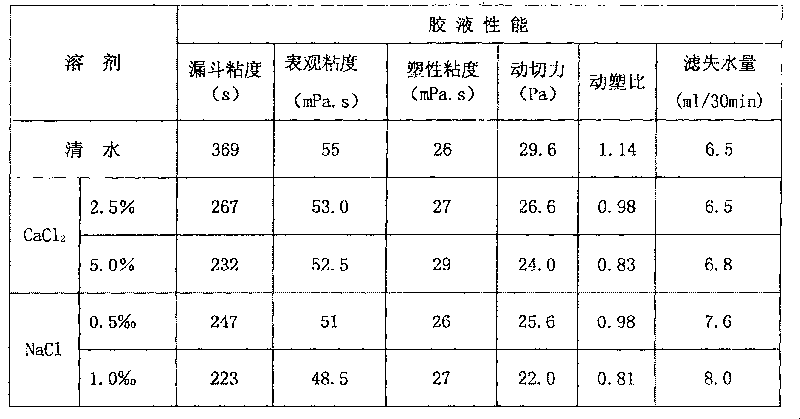

[0128] Present embodiment 2 bitter bean plant gum type environmental protection mud is characterized in that comprising following components:

[0129] Bitter Bean Vegetable Gum 8g

[0130] 0.4 grams of hydrolyzed polyacrylamide with a molecular weight of 18 million

[0131] Sodium hydroxide 0.4 g

[0132] 1000ml of water.

[0133] The preparation method of the present embodiment 2 bitter bean plant glue type environmental protection mud is to proportion the ingredients, add bitter bean plant glue into the water, stir while adding, stir for 30 minutes and wait for it to completely dissolve, then add the hydrolyzed polyacrylamide In the glue solution, continue to stir for 30 minutes, then add sodium hydroxide, and stir for 15 minutes to form a bitter bean plant glue-type environmentally friendly mud.

[0134] The preparation method of the present embodiment 2 bitter bean vegetable gum is the same as that of embodiment 1.

Embodiment 3

[0136] Present embodiment 3 bitter bean vegetable gum type environmental protection mud, comprises following components:

[0137] Bitter Bean Vegetable Gum 12g

[0138] 0.6 grams of hydrolyzed polyacrylamide with a molecular weight of 18 million

[0139] Sodium hydroxide 0.6 g

[0140] 1000ml of water.

[0141] In Example 3, the preparation method of the bitter bean plant gum type environmental protection mud is the same as that in Example 2.

[0142] The preparation method of the bitter bean vegetable gum of the present embodiment 3 is the same as that of the embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com