Heat bimetallic strip steel surface printing technique

A thermal bimetal, printing process technology, applied in printing, printing devices, chemical instruments and methods, etc., can solve problems such as disappearance of identification marks, contamination of heat treatment equipment, blurred marks, etc., to achieve the effect of easy observation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

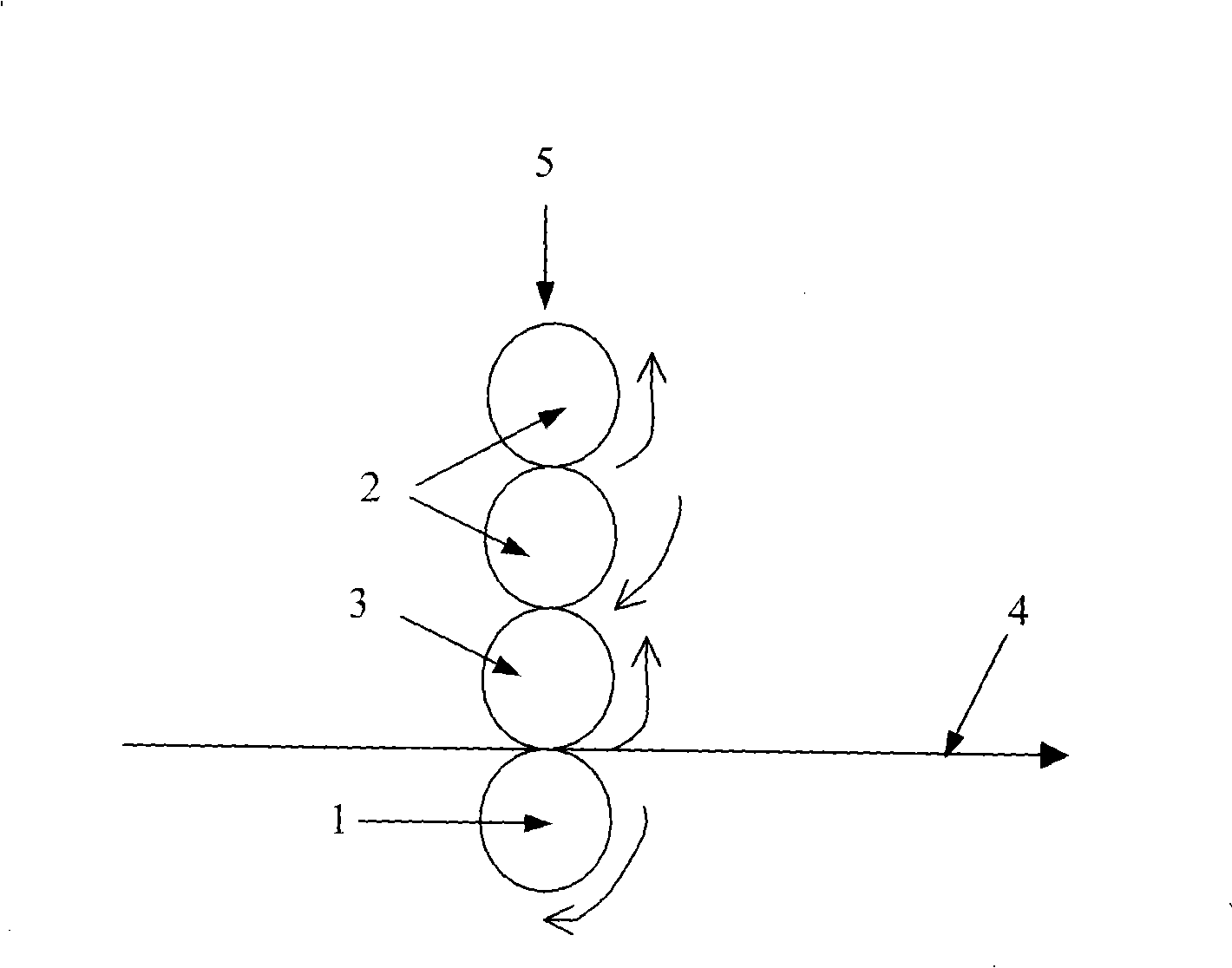

Image

Examples

Example Embodiment

[0032] The present invention adopts the chemical etching etching method to carry out the technical scheme of continuously printing a certain pattern or handwriting on the surface of the strip material:

[0033] Process flow: hot bimetallic cold rolled strip → detergent (40~70℃)→washing (40~70℃)→baking (50~70℃)→printing→neutralizing with lye→water washing (40~70℃) ℃)→baking (50~70℃)→applying anti-rust oil→winding→inspection→warehousing.

[0034] Among them, surface degreasing: it is very important to remove oil stains on the surface during printing production operations. If the oil stains on the surface are not removed, an oil film will form on the surface of the strip to protect the surface of the strip from being corroded or to reduce corrosion, resulting in post-printing The surface of the steel strip has no writing or light writing, and is easily removed by subsequent process friction.

[0035] Solution Preparation: See Table 1.

[0036] When preparing the solution, it sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com