Upper back-up roll extractor of cluster roll

A roll changing device and a technology for supporting rolls, which are applied to the field of roll changing devices for supporting rolls on a multi-roll mill, can solve problems such as long roll changing time, and achieve the effects of reducing roll changing time, improving production work rate, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation of the backup roll changing device for a multi-roll rolling mill of the present invention will be further described below in conjunction with the accompanying drawings.

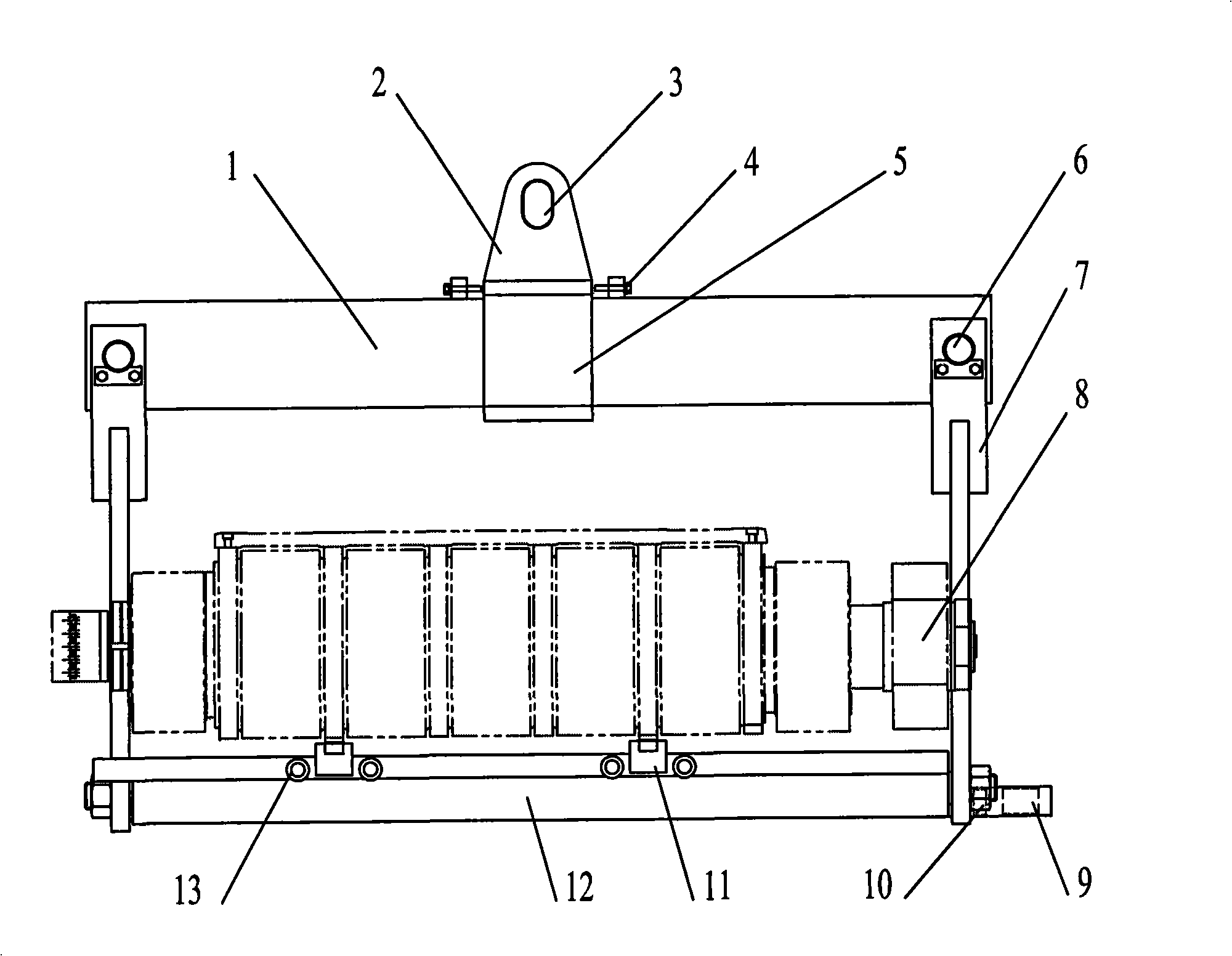

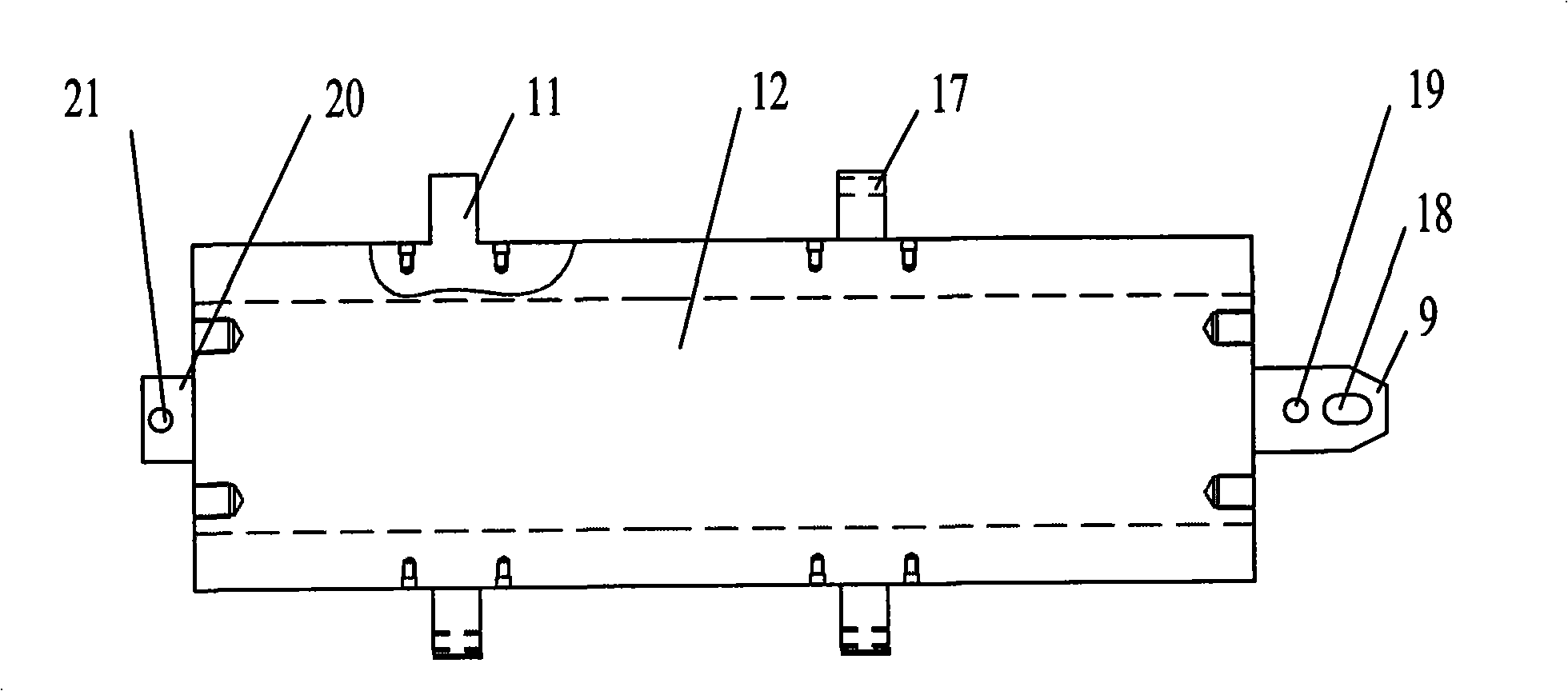

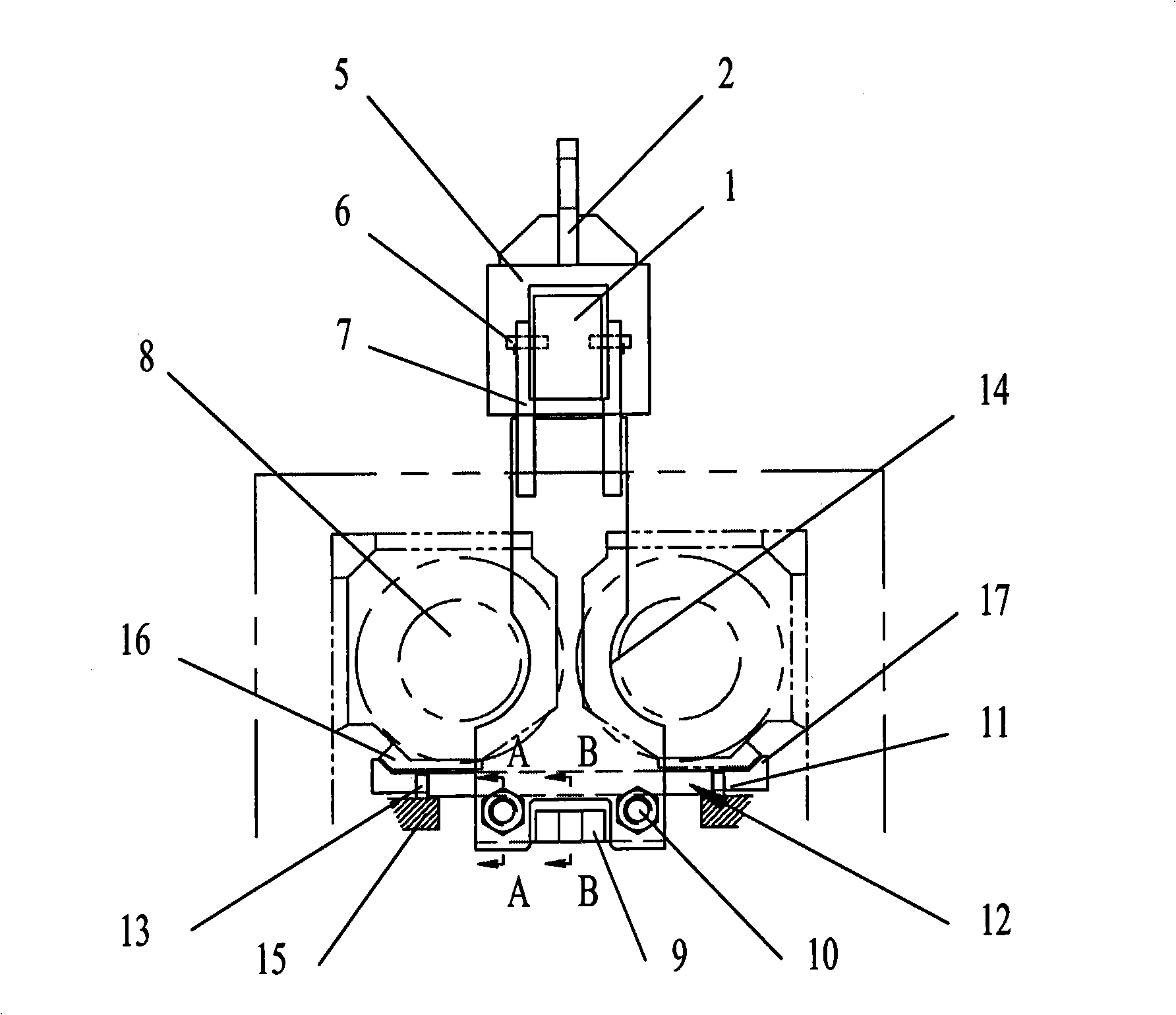

[0026] see figure 1 , 2 and 3, the support roll changing device for a multi-roll rolling mill according to the present invention, comprising a roll changing bracket and a hanger for hanging the roll changing bracket. Wherein: the hanger includes a beam 1, a lifting lug 2 set on the beam 1 and a swingable hanger 7 connected to both ends of the beam 1 through a pin shaft 6, and the two sides of the lifting lug 2 on the beam 1 are provided with limited Position bolts 4; the roller changing bracket includes a vehicle frame 12 and a roller 13 installed on the vehicle frame 12, the vehicle frame 12 includes a main body frame and at least one end has an upward direction on opposite sides of the main body frame. The side guide plate 11 of protrusion 17 preferably makes the space f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com