Polypiperazine-amide nanofiltration membrane and preparation method thereof

A technology of polypiperazine amide and nanofiltration membrane, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effect of broadening the selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 is that the piperazine aqueous solution that mass volume concentration is 1% is covered on the polysulfone supporting layer surface of wet state 3 minutes, pours off excess solution then, dries in the air for 6 minutes, then compares with mass volume concentration (g / ml) 0.2% isopar solution of 3,3′,5,5′-bipyrellithyl chloride (isopar purchased from Idemitsu Chemical Co. Ltd., Japan) was contacted on one side for interfacial polymerization reaction for 90 seconds. It was then subjected to the first heat treatment: 5 minutes at 80°C. Then carry out two-step rinsing: the first step is to rinse in 40° C. ethanol weight ratio of 10% aqueous solution for 20 minutes, and the second step is to rinse in 40° C. water for 20 minutes. Finally, the second heat treatment step is performed: treating at 100° C. for 5 minutes to obtain a polypiperazine amide nanofiltration membrane.

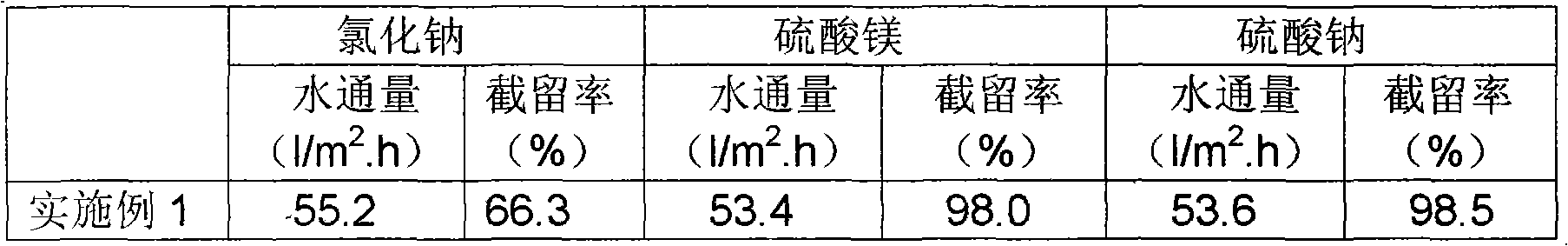

[0025] The test results are:

[0026]

[0027] Examples 2-6. The mass volume concen...

Embodiment 26-29

[0040] Examples 26-29. 3,3',5,5'-biphenyltetrayl chloride was used, and its mass volume concentration was 0.05, 0.1, 0.3, 0.5% respectively, and the rest of the conditions were the same as in Example 1. The test results are:

[0041]

[0042] Examples 30-34. 2,2',4,4'-biphenyltetrayl chloride was used, and its mass volume concentration was 0.05, 0.1, 0.2, 0.3, 0.5% respectively, and the rest of the conditions were the same as in Example 1. The test results are:

[0043]

Embodiment 35-39

[0044] Examples 35-39. 2,2',5,5'-biphenyltetraoyl chloride was used, and its mass volume concentration was 0.05, 0.1, 0.2, 0.3, 0.5% respectively, and the rest of the conditions were the same as in Example 1. The test results are:

[0045]

[0046] Examples 40-44. Adopt the mixture of 3,3',5,5'-biphenyltetrayl chloride and trimesoyl chloride, the total mass volume concentration is 0.2%, and its weight ratio 3,3',5,5'-biphenyltetrayl chloride: Trimellitic trichloride was 10:1, 5:1, 1:1, 1:10, 1:50 respectively, and the remaining conditions were the same as in Example 1. The test results are:

[0047]

[0048]

[0049] Examples 45-49. Adopt the mixture of 2,2',4,4'-bipyrellitic acid chloride and trimesoyl chloride, the total mass volume concentration is 0.2%, its weight ratio 2,2',4,4'-bipyrellitic acid chloride: Trimellitic trichloride was 10:1, 5:1, 1:1, 1:10, 1:50 respectively, and the remaining conditions were the same as in Example 1. The test results are:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass volume concentration | aaaaa | aaaaa |

| Mass volume concentration | aaaaa | aaaaa |

| Volume concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com