Double-circulating fluid bed system for chemical chain combustion

A technology of chemical chain combustion and fluidized bed, which is applied to the fuel, fluidized bed combustion equipment, combustion method and other directions of melting state combustion, which can solve the problems of poor controllability and stability, reducing system efficiency and increasing system energy consumption. , to achieve the effect of improving stability, reducing system energy consumption, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

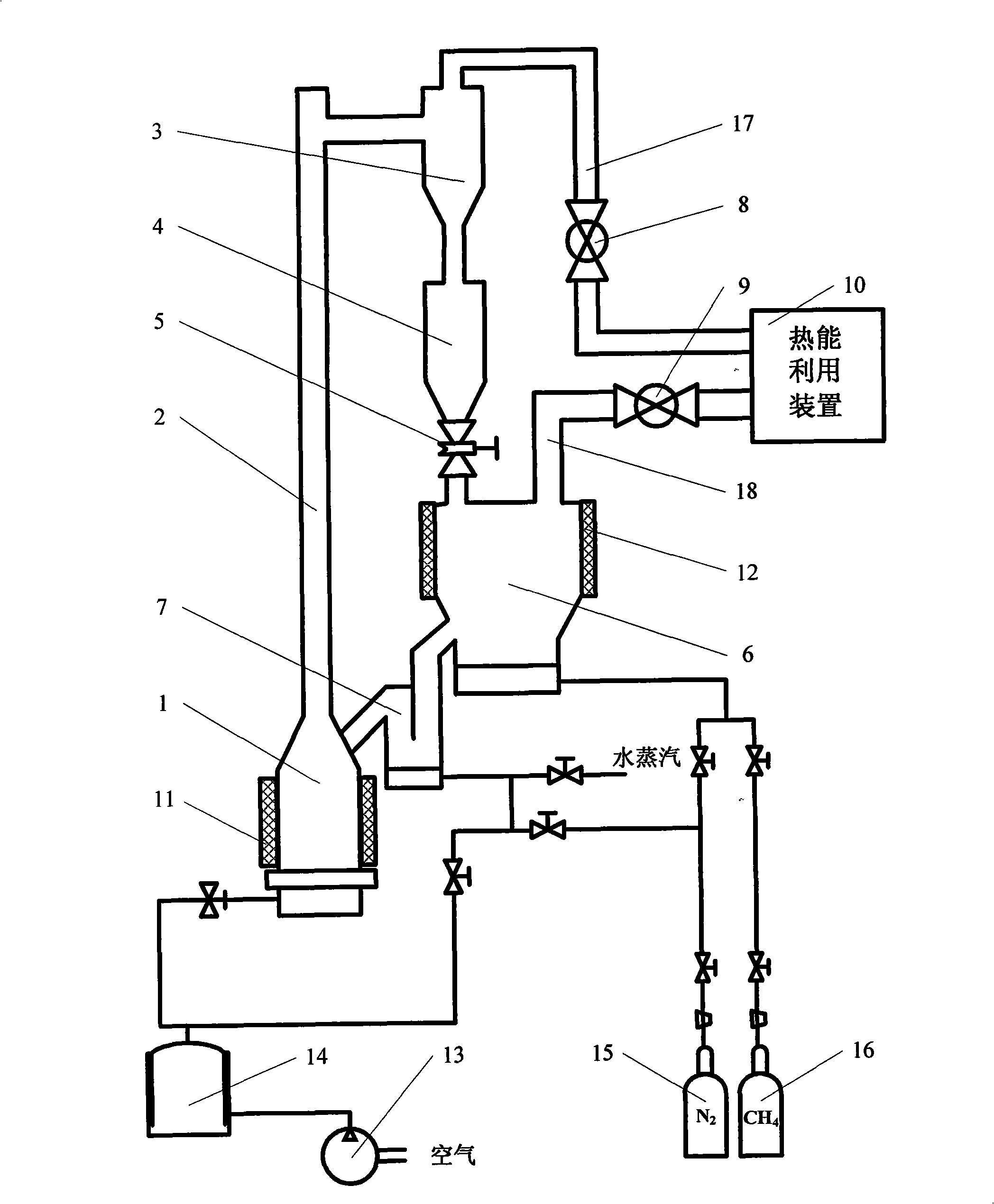

[0011] refer to figure 1 , in the present invention, fast fluidized bed 1, riser 2, cyclone separator 3, oxygen-carrying agent reservoir 4, solid flow control valve 5, bubbling bed 6, flow sealing valve 7 are connected successively, constitute the oxygen-carrying agent circulatory system. In the system, the positions and heights of the cyclone separator 3, the oxygen-carrying agent storage 4, the solid flow control valve 5, the bubbling bed 6, the flow sealing valve 7, and the fast fluidized bed 1 decrease successively.

[0012] The cyclone separator 3 is connected with the thermal energy utilization device 10 through the first exhaust pipe 17, and the first back pressure valve 8 is arranged on the first exhaust pipe 17; the bubbling bed is connected with the thermal energy utilization device 10 through the second exhaust pipe 18 , the second exhaust pipe 18 is provided with a second back pressure valve 9 .

[0013] A first heater 11 is arranged on the periphery of the fast ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com