Voltage sensitive ceramic and alumina ceramic composite insulation structure and preparation

A technology of alumina ceramics and composite insulation, which is applied in the field of composite insulation structure and preparation of voltage-sensitive ceramics and alumina ceramics, and can solve problems such as poor reliability and unstable material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

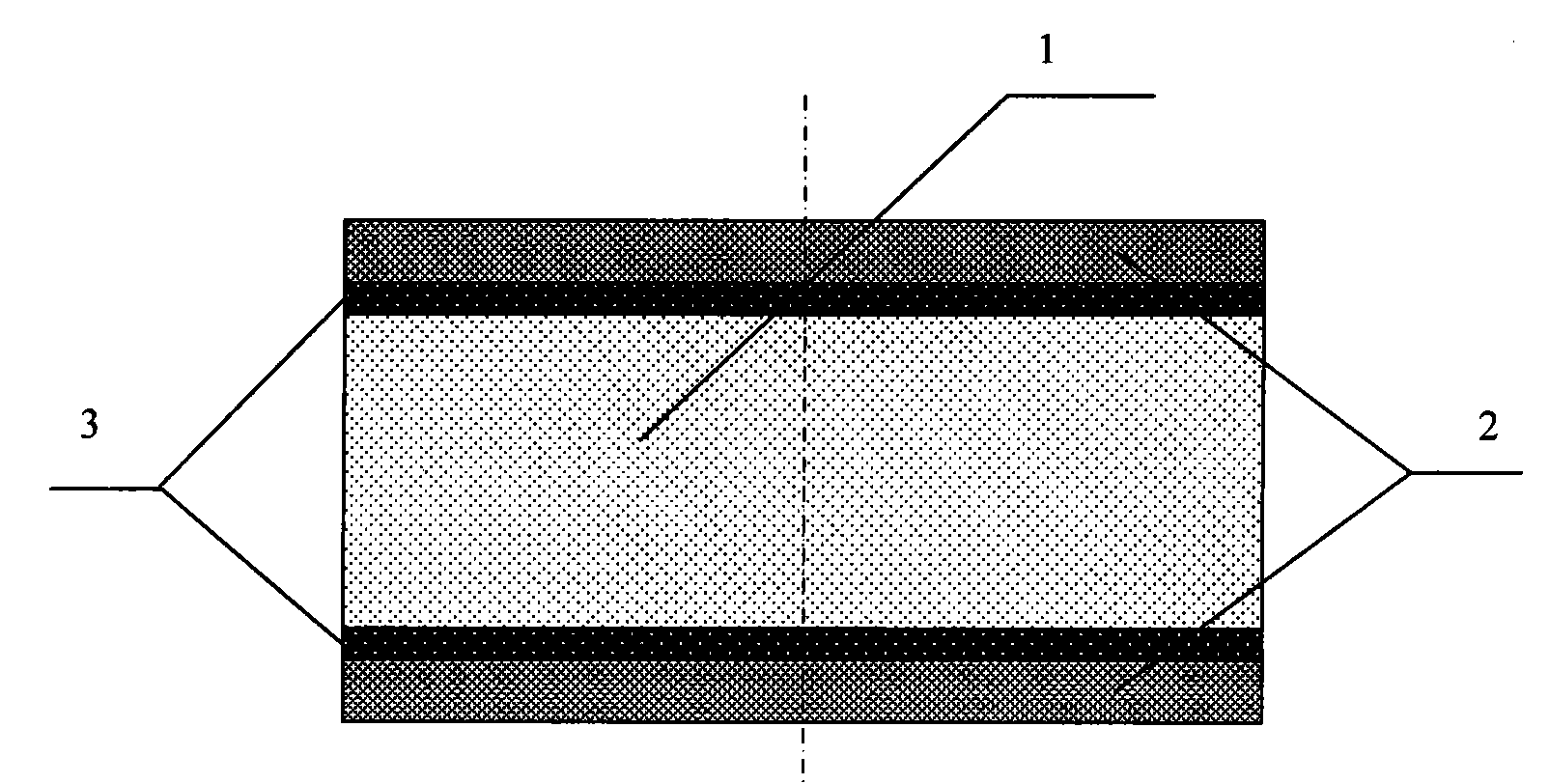

[0021] A method for preparing a composite insulating structure of voltage-sensitive ceramics and alumina ceramics, comprising the following steps:

[0022] 1) The columnar alumina ceramic substrate 1 is prepared by conventional electronic ceramic technology, and its two ends are ground flat; the columnar alumina ceramic substrate 1 can be 75, 85 or 95Al 2 o 3 porcelain body.

[0023] 2) The voltage-sensitive ceramic wafer 2 is made of ZnO ceramics with different potential gradients, and the specific gradients are shown in Table 1:

[0024] Table 1 ZnO ceramic potential gradient

[0025] ZnO ceramics

A

B

C

D

E

F

G

H

I

Potential gradient (V)

60

145

200

300

400

450

490

530

550

[0026] 3) Bond the above-mentioned voltage-sensitive ceramic disc 2 with epoxy adhesive on both ends of the columnar alumina ceramic substrate 1; the thickness of the voltage-sensitive ceramic disc 2 is 1mm; the thickness of t...

Embodiment 2

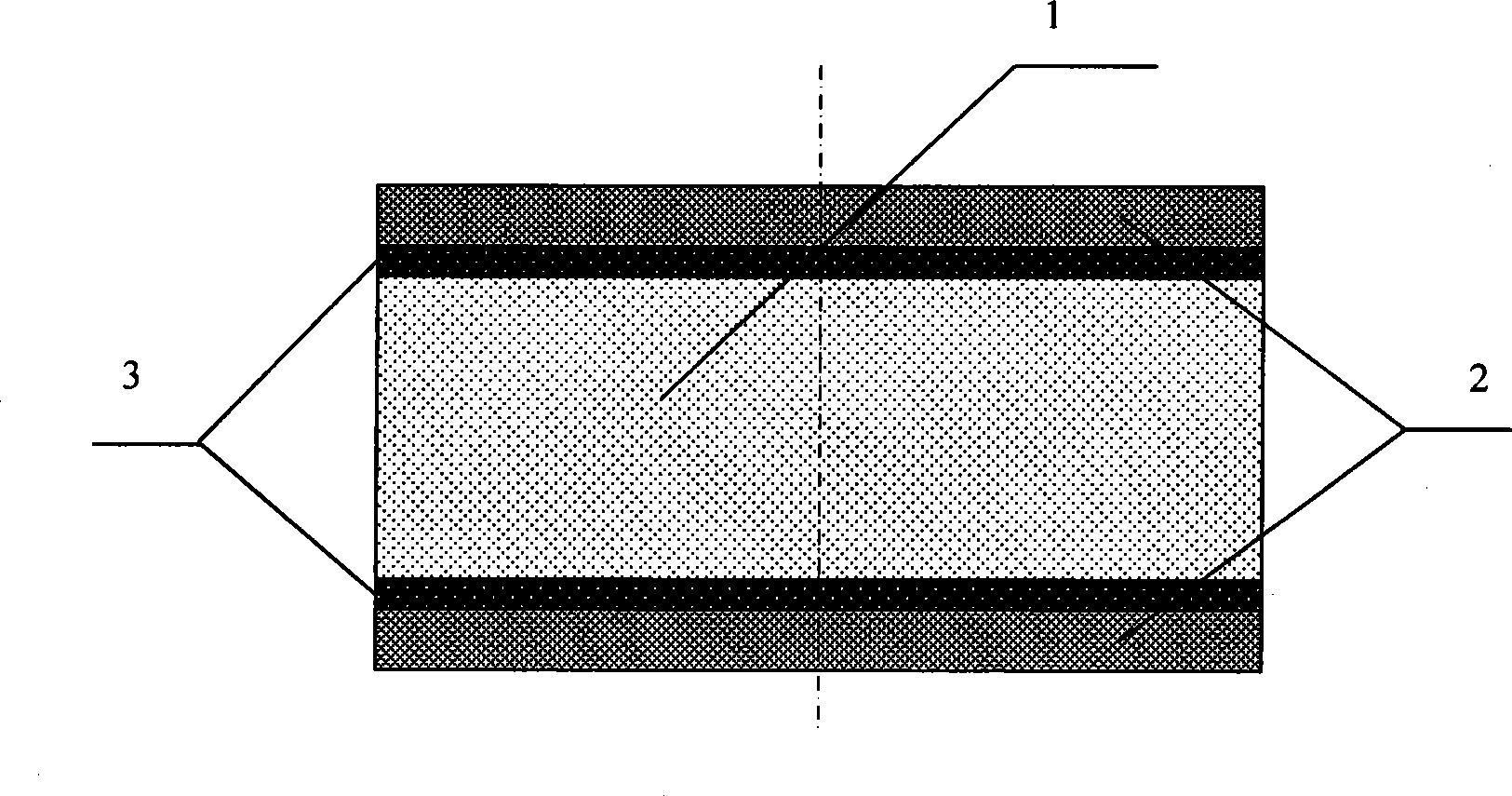

[0029] Step 1), step 2) are with embodiment one;

[0030] 3) Bonding the voltage-sensitive ceramic disc 2 with a low-temperature glass adhesive on both ends of the cylindrical alumina ceramic substrate 1;

[0031] 4) Put the columnar alumina ceramic substrate bonded with the voltage-sensitive ceramic disc into a high-temperature furnace and heat to 500° C. for sintering so that the pressure-sensitive ceramic sheet and the alumina ceramic substrate are connected together.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com