Satellite type gravure press

A gravure printing machine and satellite technology, which is applied in gravure rotary printing machines, printing machines, rotary printing machines, etc., can solve the problems of difficulty in grasping the proportion of antioxidants, increase in production cost of printed matter, and affect printing quality, etc., and achieve power consumption. Low, increased efficiency, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

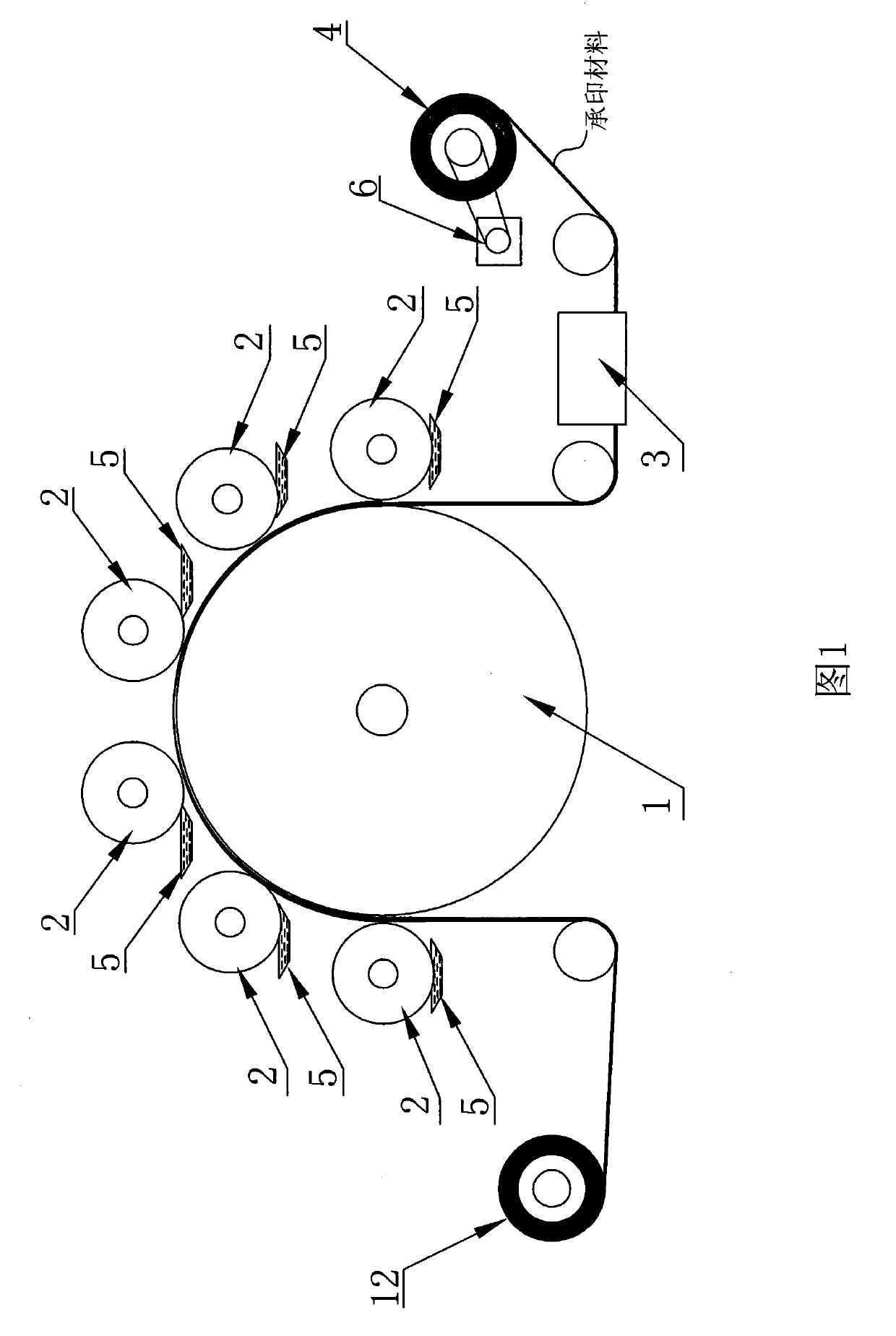

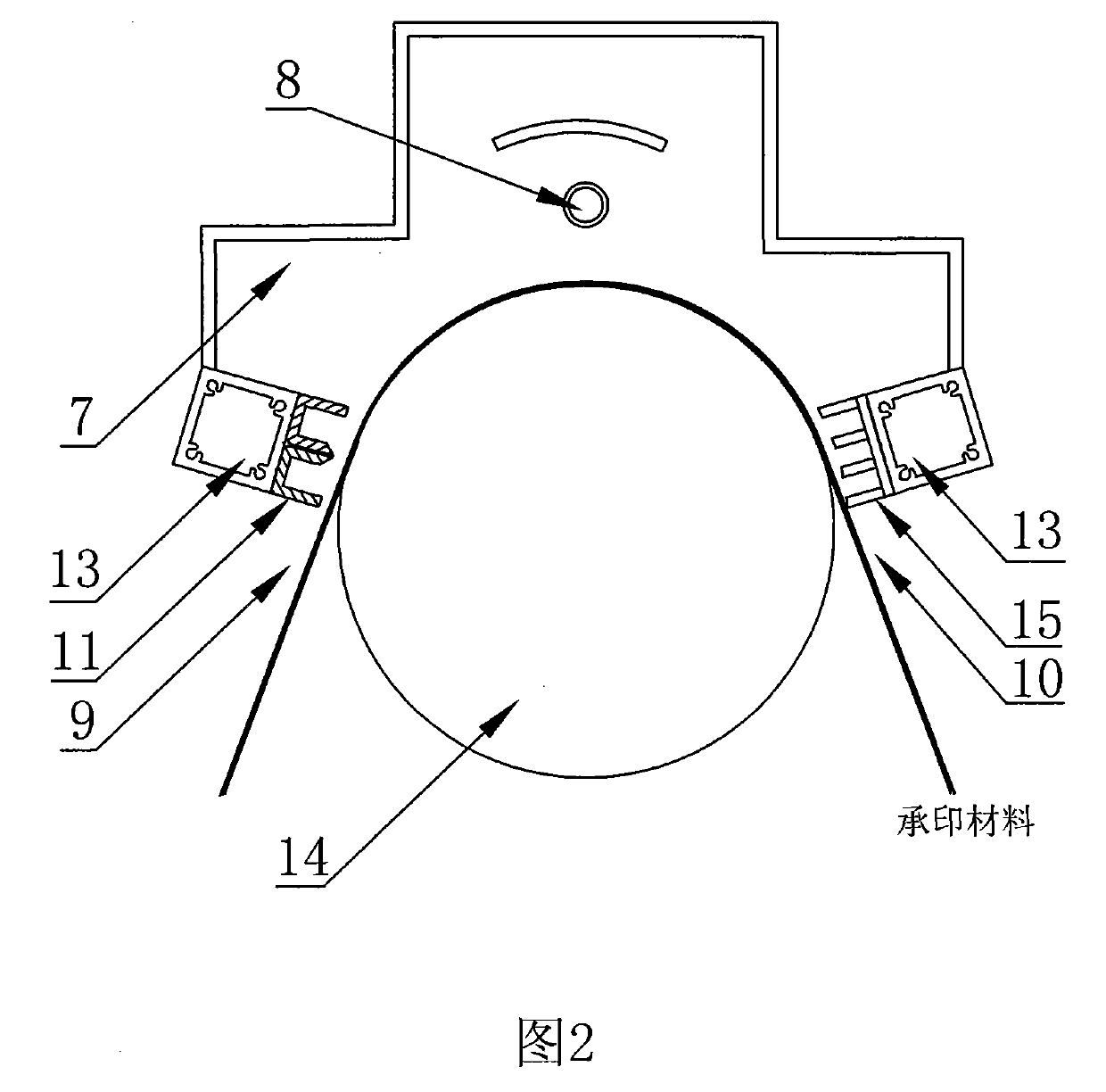

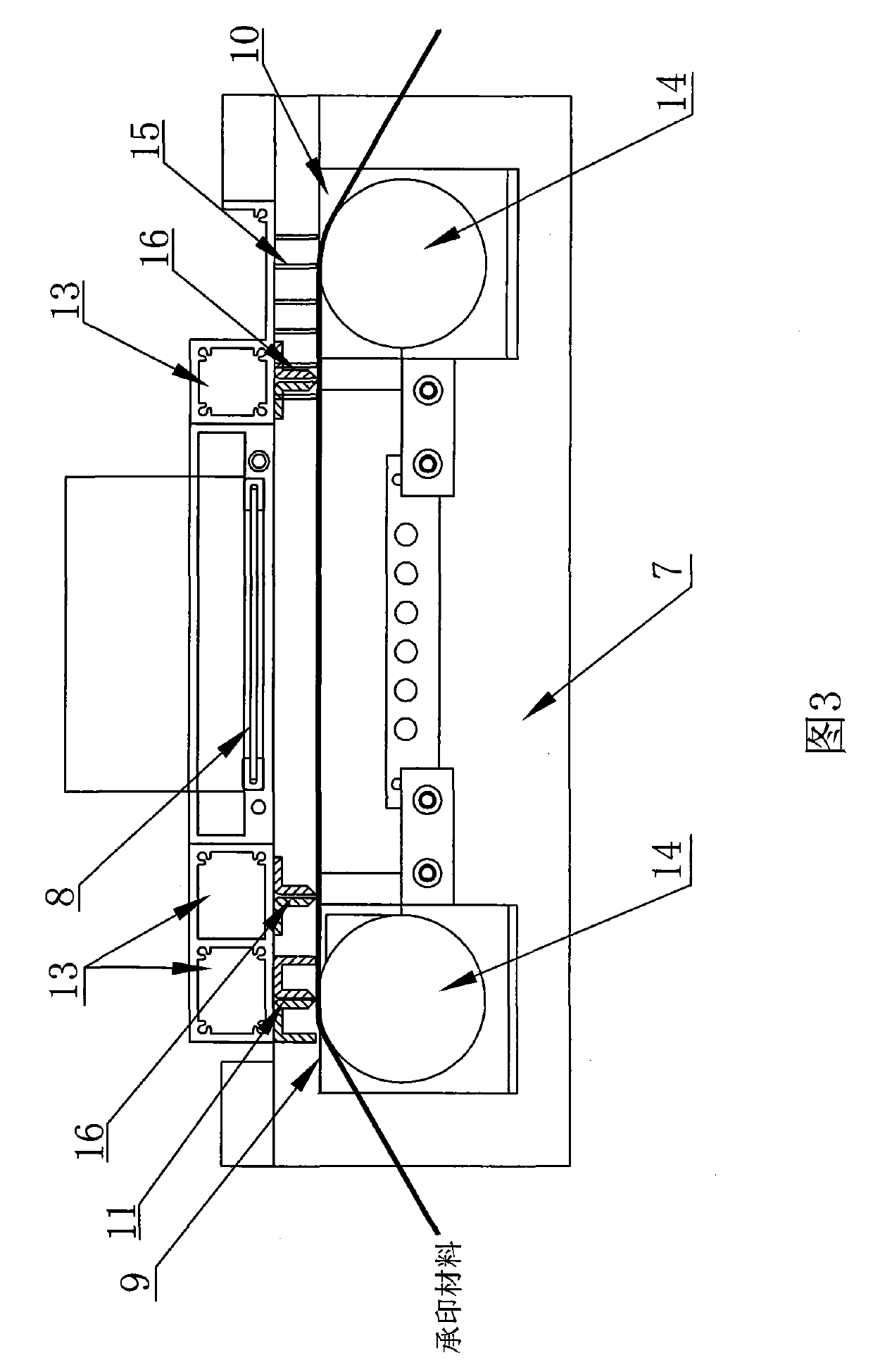

[0013] Referring to Fig. 1, Fig. 2 and Fig. 3, the satellite type gravure printing machine includes an unwinding roller 12, a printing mechanism, a drying mechanism 3 and a winding roller arranged in sequence, wherein the printing mechanism includes a pressure roller 1 and a plate roller 2, The bottom of the version roller 2 is provided with an ink cartridge 5; the winding roller 4 is connected with a power device 6 that drives it to rotate, and is characterized in that two or more version rollers 2 are distributed along the circumference of the pressure roller 1; the drying mechanism 3. It includes a light box 7 filled with oxygen-free protective gas. An ultraviolet lamp tube 8 is installed in the light box 7. The two ends of the light box 7 are provided with an inlet 9 and an outlet 10 for printing materials. 1. An air knife 11 for oxygen clearing treatment, the air knife 11 is provided with an air jet port, and an air stop device 12 is provided at the outlet to prevent outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com