Hammer leaf type drum sieve pulverizing machine

A trommel screen and pulverizer technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of low pulverization efficiency, poor micro pulverization effect, motor power loss, etc., to improve the screening ability, improve pulverization efficiency, Guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

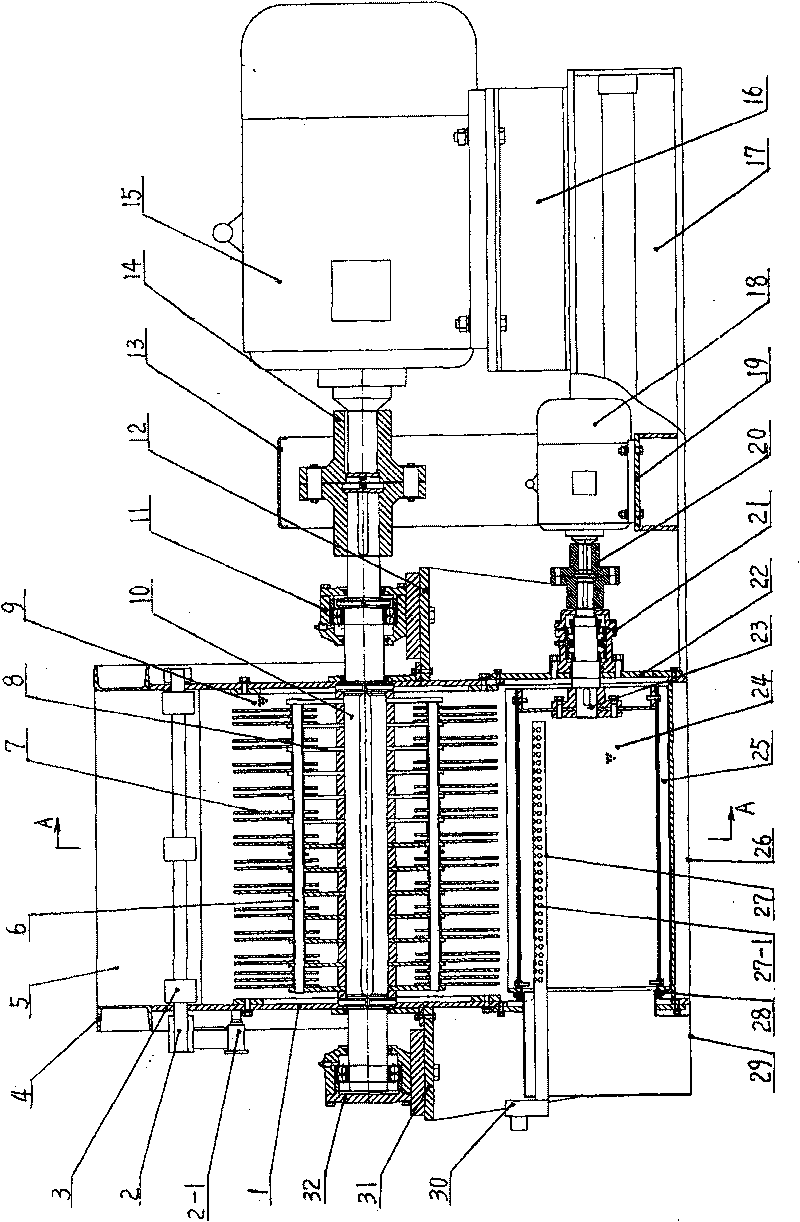

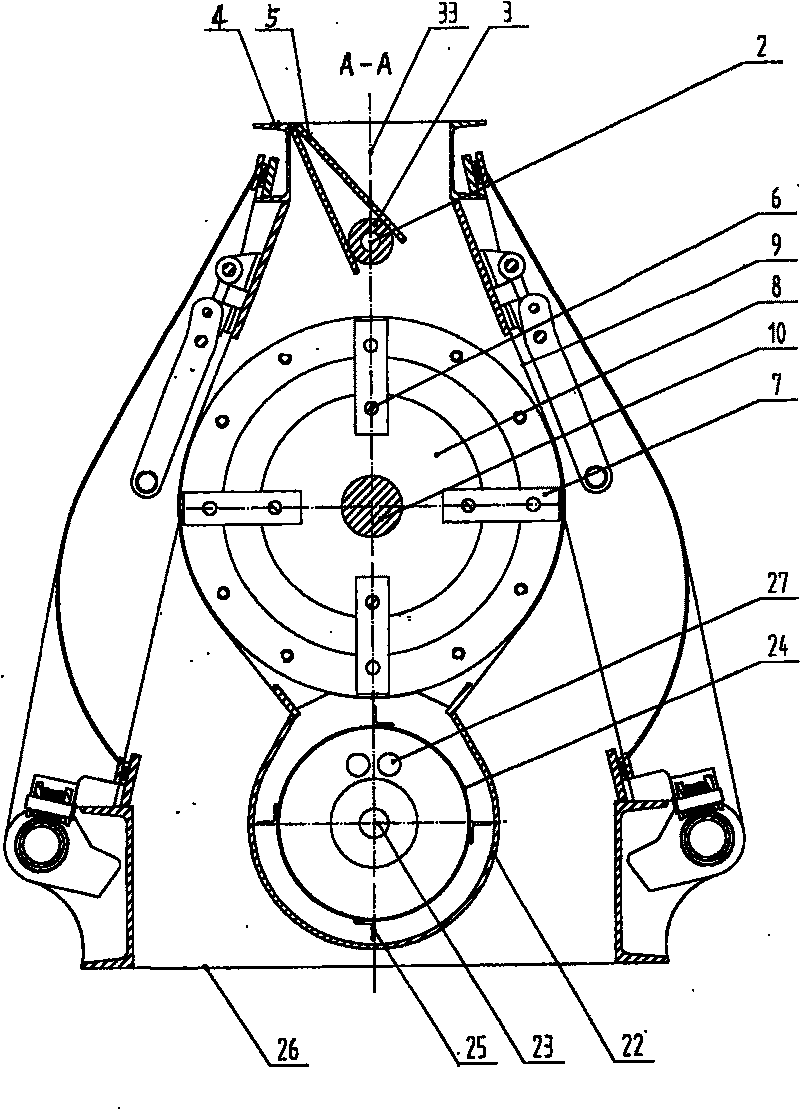

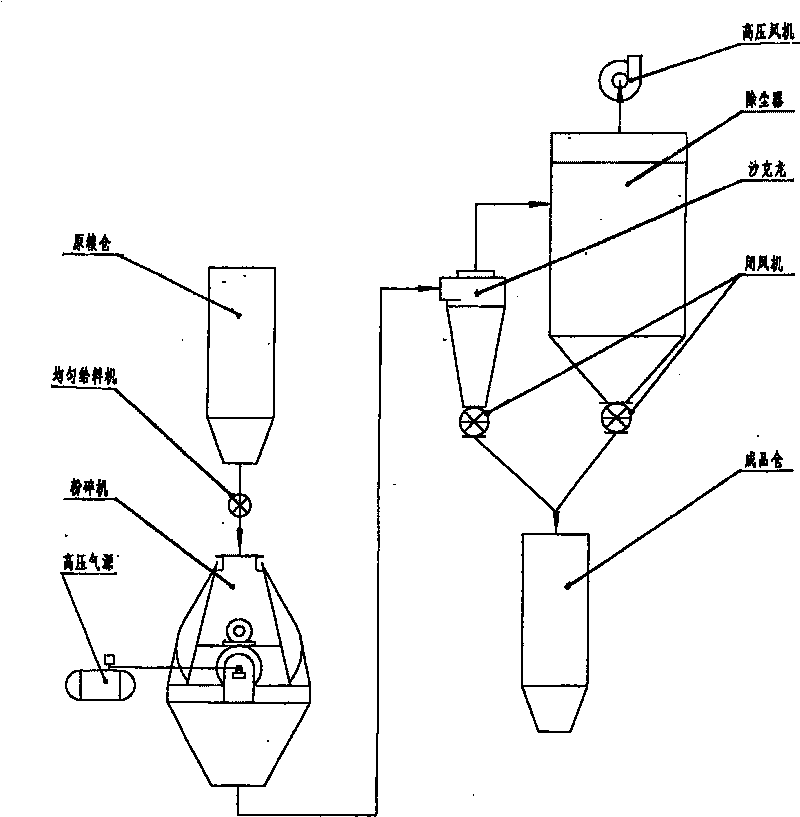

[0011] Examples, see attached figure 1 , 2 , a main motor seat 16 is fixed on the right end surface of the base 17 of the hammer-type trommel mill and its crushing method, the main motor seat 15 is fixed above the main motor seat 16, and the main motor 15 shaft is connected to the pulverizer main shaft 10 with a coupler-14, Dress cover 13 above shaft coupling one 14. Bearing block 3 32 and bearing block 11 at the left and right ends of the pulverizer main shaft 10 are fixed on the bearing block 3 support 31 and bearing seat 1 support 12, and the rotor 8 is fixed on the circumferential surface of the pulverizer main shaft 10, and the blades of the rotor 8 Several hammer shafts 6 are fixed in the middle, and several hammers 7 are fixed on the hammer shafts 6; a pulverizer sieve 9 is fixed on the outer pulverizer shell of the hammer 7, and the pulverizer rotor 8 is installed on the lower end belt. In the open drop-shaped casing 1. The upper end of the pulverizer shell 1 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com