Automatic winding device of mechanical clock

A technology for automatic winding and clocks, which is applied in the field of clocks and watches, and can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

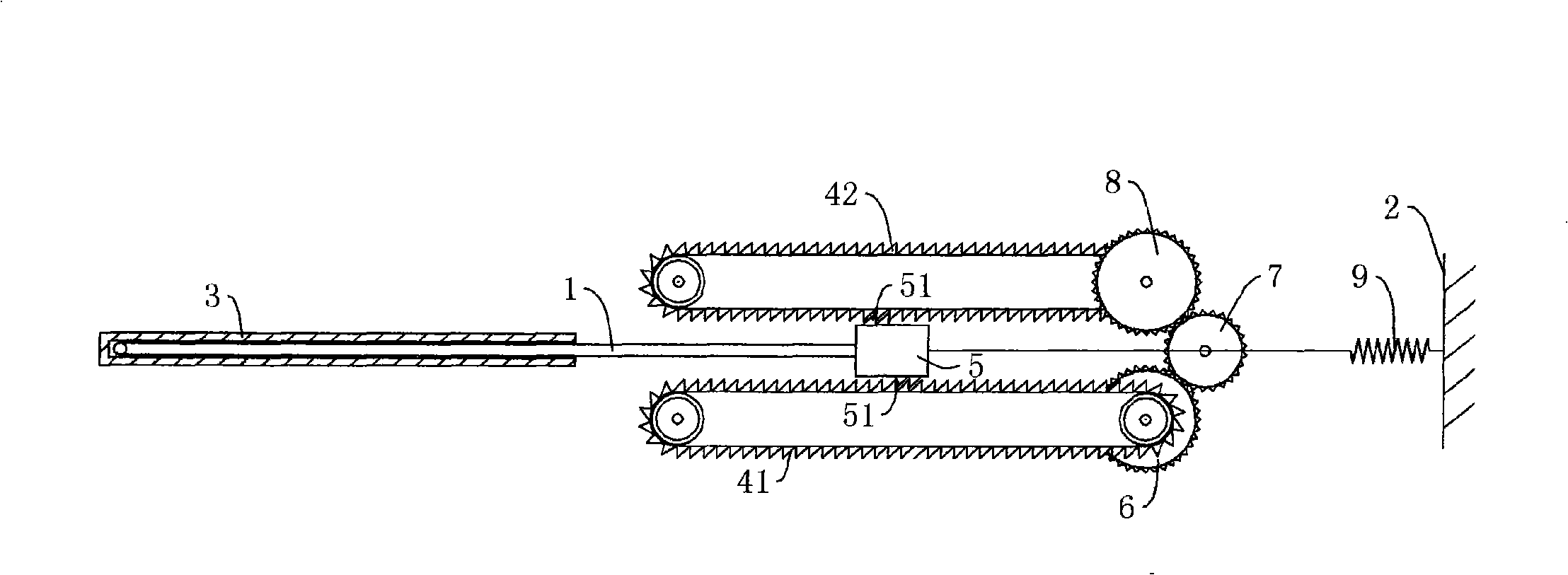

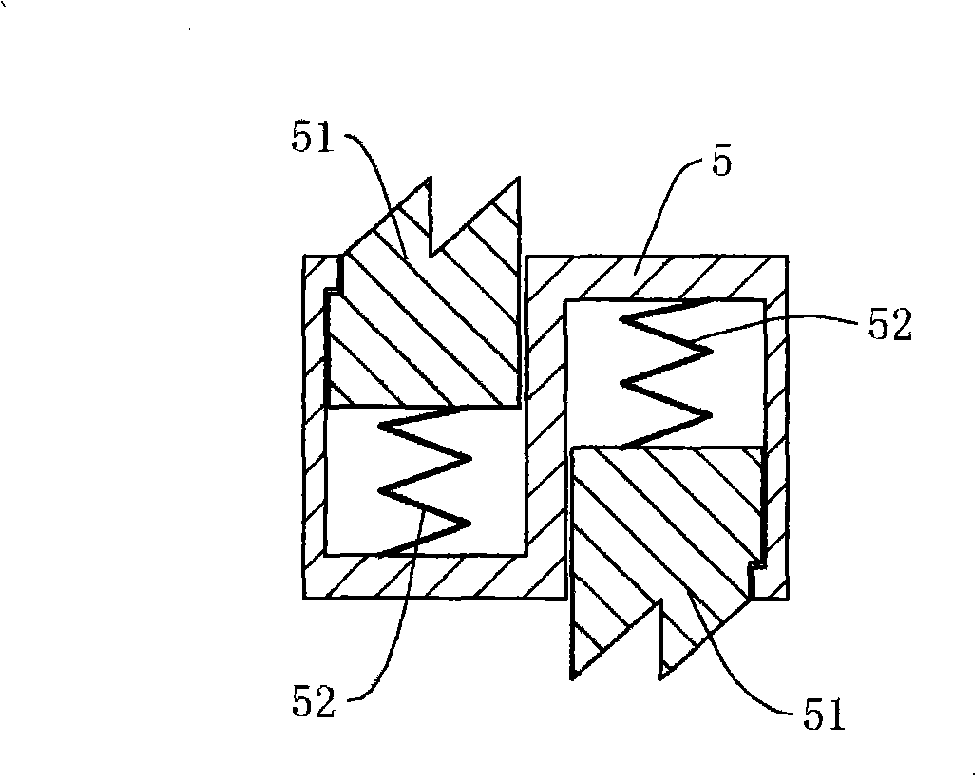

[0013] like figure 1 As shown, the automatic winding device for mechanical clocks and watches includes a watch body 2, in which a clockwork shaft gear 7 for winding is provided, and in the watch body 2 is provided a temperature-sensitive memory that can sense temperature changes and produce stretching Metal strip 1, a unidirectional push device for making the spring shaft gear 7 rotate in one direction is provided between the temperature-sensitive memory metal strip 1 and the clockwork shaft gear 7, and the temperature-sensitive memory metal strip 1 can be made of a conventional memory alloy The temperature-sensitive memory metal strip 1 senses temperature changes and expands and contracts to push the one-way push device, so that the mainspring shaft gear 7 rotates in one direction to realize automatic winding. With this structure, no matter whether the mechanical clock is in motion or static, as long as There are differences and changes in the external temperature, and the au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com