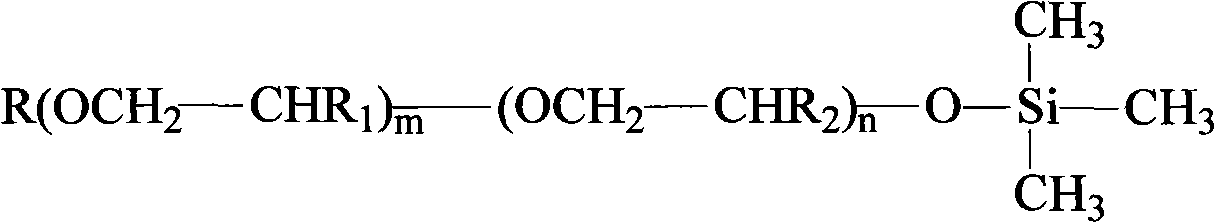

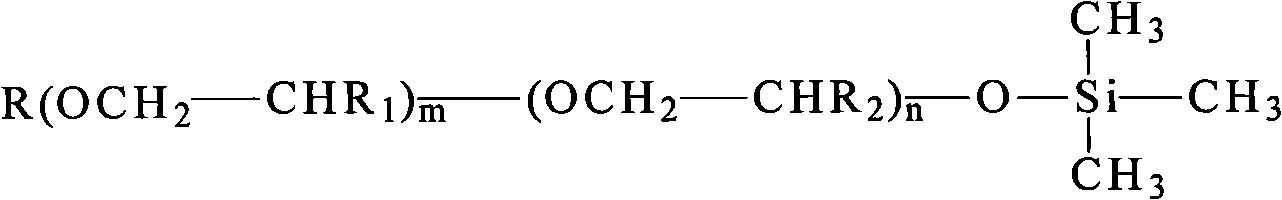

End capping polyether prepared with end hydroxyl radical polyether and preparation thereof

A technology of hydroxyl-terminated polyether and capped polyether, which is applied in the field of capped polyether and its preparation, and can solve problems such as low capping rate and unstable capping rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add allyl alcohol polyether (its structure is CH 2 =CH-CH 2 -(OCH 2 CH 2 ) 10 -(OCH 2 CHCH 3 ) 4 OH) 350g, add 45g of sodium hydroxide, and add co-solvent methanol 100ml, react at -0.08~-0.10Mpa, 85°C for 2.5 hours; cool down to 60°C, dropwise add trimethylchlorosilane 83g, about 1 hour After the dropwise addition is completed, the reaction is continued for 1.5 hours; the pH value of the reaction product is adjusted to 5-6 with acid, and diatomaceous earth and polyether refining preparation are added for treatment for 2 hours to obtain a blocked polyether.

[0021] The end-capped polyether prepared in this example, the end-capping rate is shown in Table 1 through infrared test analysis.

Embodiment 2

[0023] Add allyl alcohol polyether (its structure is CH 2 =CH-CH 2 -(OCH 2 CH 2 ) 16 -(OCH 2 CHCH 3 ) 7 OH) 500g, add 25g of sodium hydroxide, and 50ml of co-solvent methanol, react at -0.08~-0.10Mpa, 80°C for 3.0 hours; cool down to 60°C, dropwise add trimethylchlorosilane 60g, about 40 minutes After the dropwise addition is completed, the reaction is continued for 1.0 hour; the pH value of the reaction product is adjusted to 5-6 with acid, and diatomaceous earth and polyether refining preparation are added for treatment for 2 hours to obtain a blocked polyether.

[0024] The end-capped polyether prepared in this example, the end-capping rate is shown in Table 1 through infrared test analysis.

Embodiment 3

[0026] Add allyl alcohol polyether (its structure is CH 2 =CH-CH 2 -(OCH 2 CH 2 ) 10 -(OCH 2 CHCH 3 ) 4 OH) 350g, add 40g sodium methoxide, and add 100ml co-solvent methanol, react at -0.08~-0.10Mpa, 120°C for 2.5 hours; cool down to 60°C, drop trimethylchlorosilane 80g, about 1 hour After the addition is completed, the reaction is continued for 1.5 hours after the dropwise addition; the pH value of the reaction product is adjusted to 5-6 with an acid, and diatomaceous earth and polyether refining preparation are added for treatment for 2 hours to obtain a blocked polyether.

[0027] The end-capped polyether prepared in this example, the end-capping rate is shown in Table 1 through infrared test analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com