Shampoo composition for removing dandruff

A shampoo composition and the technology of the composition are applied in the field of daily chemicals and can solve problems such as dry hair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

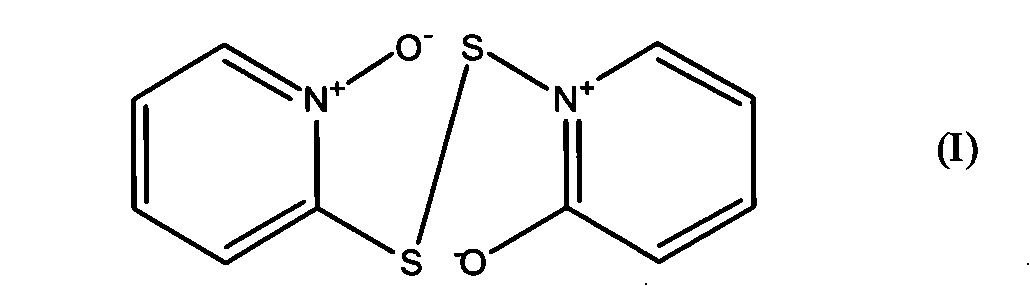

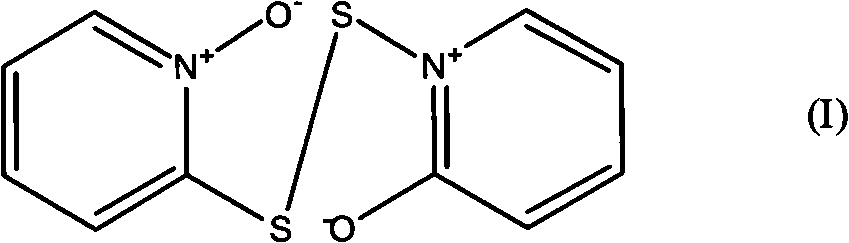

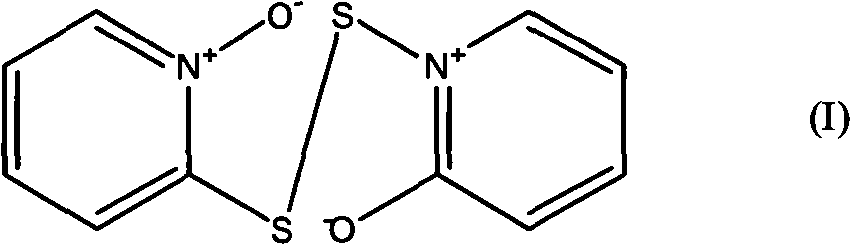

Image

Examples

preparation Embodiment I-X

[0040] A suitable method for preparing the anti-dandruff shampoo composition described in Examples I-X is as follows: add an appropriate amount of water into the reaction tank, add polyquaternium-10 under slow stirring to disperse, heat to 60°C to 80°C under slow stirring ℃, followed by adding a pH adjuster (such as citric acid), ammonium lauryl alkyl sulfate, ammonium lauryl polyoxyethylene ether sulfate, cocamidopropyl sulfobetaine, sodium lauryl amphoacetate, fatty acid monoethanolamide, Cetyltrimethylammonium chloride, pearl flakes, disodium edetate (if using these substances), let these substances completely disperse and cool down. When the temperature drops to about 65°C, add anti-dandruff agent bispyridinethione, after the dispersion is uniform, cool down to below 50°C, add polydimethylsiloxane and nutritional additives to disperse evenly, then add preservatives, pigments, flavors, etc. and continue stirring , to ensure a homogeneous mixture. After adding all the compo...

Embodiment I-V

[0042] weight(%)

[0043] components

[0044] I II III IV V

[0045] Ammonium lauryl sulfate (70%) 8.0 8.0 8.0 8.0 8.0

[0046] Ammonium Laureth Sulfate (70%) 10.0 10.0 12.0 12.0 12.0

[0047] Cocamidopropyl sulfobetaine 6.0 6.0 6.0 6.0 6.0

[0048] Sodium Lauryl Amphoacetate 2.0 2.0 2.0 3.0 3.0

[0049] Cetyltrimethylammonium chloride 0.6 0.6 0.6 0.6 0.6

[0050] Polyquaternium-10 0.2 0.2 0.2 0.2 0.2

[0051] Pearl flakes 1.5 1.5 1.5 1.5 1.5

[0052] Disodium EDTA 0.1 0.1 0.1 0.1 0.1

[0053] Dipyridinethione 0.2 0.3 0.4 0.6 0.8

[0054] Dimethicone 2.0 2.0 2.5 2.5 2.5

[0055] Citric acid, preservatives, coloring agents, fragrances, sodium chloride, appropriate amount

[0056] water to 100%

Embodiment VI-X

[0058] weight(%)

[0059] components

[0060] VI VII VIII IX X

[0061] Ammonium lauryl sulfate (70%) 6.0 6.0 6.0 6.0 6.0

[0062] Ammonium Laureth Sulfate (70%) 10.0 10.0 12.0 12.0 14.0

[0063]Cocamidopropyl sulfobetaine 6.0 6.0 5.0 5.0 5.0

[0064] Sodium lauryl amphoacetate 2.0 2.0 3.0 3.0 3.0

[0065] Cetyltrimethylammonium chloride 0.6 0.6 0.6 0.6 0.6

[0066] Polyquaternium-10 0.2 0.2 0.2 0.2 0.2

[0067] Pearl flakes 1.5 1.5 1.5 1.5 1.5

[0068] Disodium EDTA 0.1 0.1 0.1 0.1 0.1

[0069] Dipyridinethione 0.2 0.5 0.6 0.7 1.0

[0070] Dimethicone 3.0 3.0 3.0 3.0 3.0

[0071] Citric acid, preservatives, coloring agents, fragrances, sodium chloride, appropriate amount

[0072] water to 100%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com