Disc clamping rotary plate

A turntable and disc technology, which is applied in the field of clamping turntables, can solve the problems of increased incidental costs of production costs, complex assembly projects, and increased project defect rates, and achieve the effects of simple manufacturing processes and reduced manufacturing costs and additional costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The features and advantages of the present invention will be made clear by the following detailed description based on the accompanying drawings.

[0062] Before the description, the terms or words used in this description and the scope of the claims are for the inventor to explain his invention in the best way, starting from the principle of giving the most appropriate definition to the terms, and should be consistent with the technical idea of the present invention meanings and concepts. In addition, please note that if it is judged that the detailed description of the known functions and configurations related to the present invention will affect the gist of the present invention, the detailed description will be omitted.

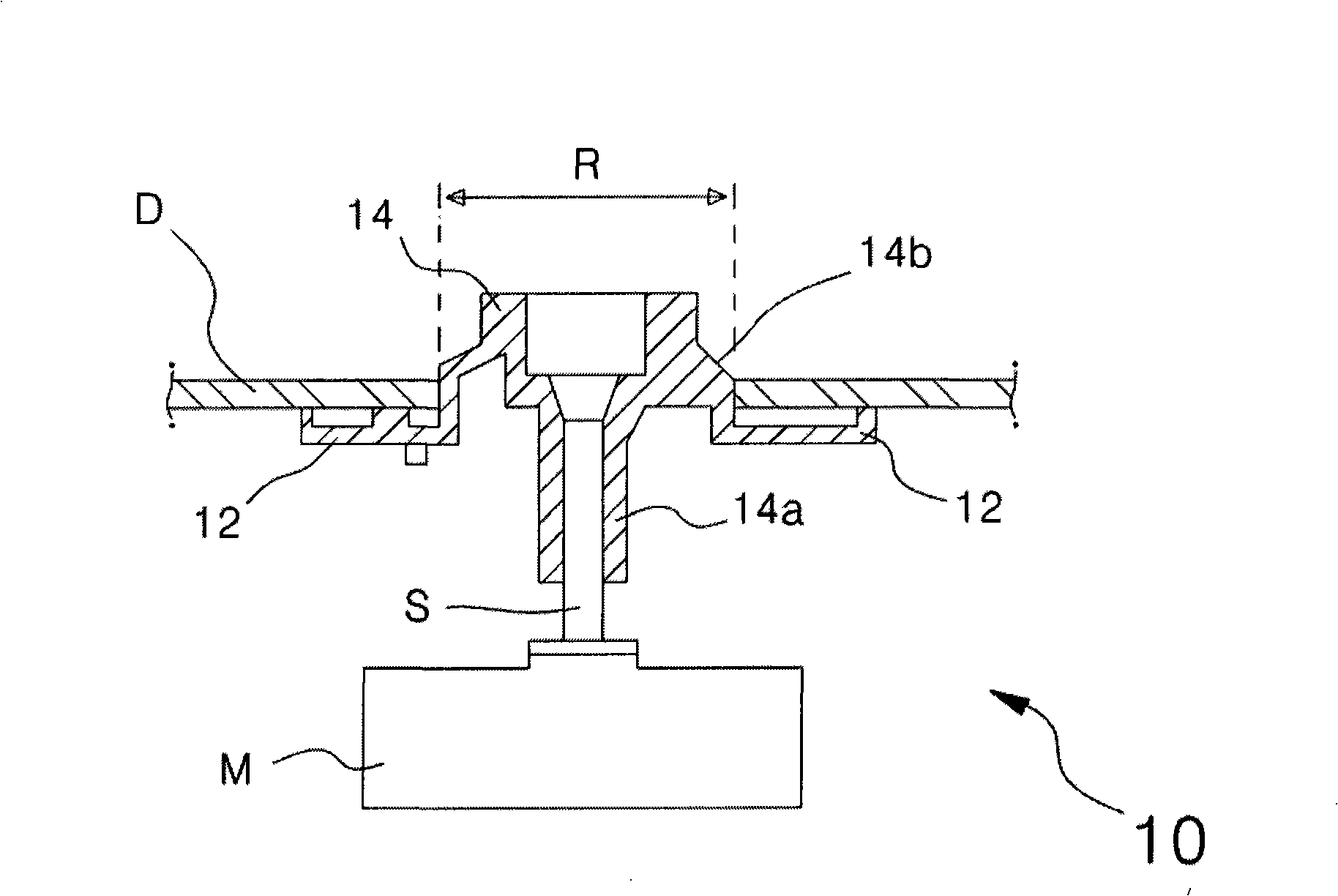

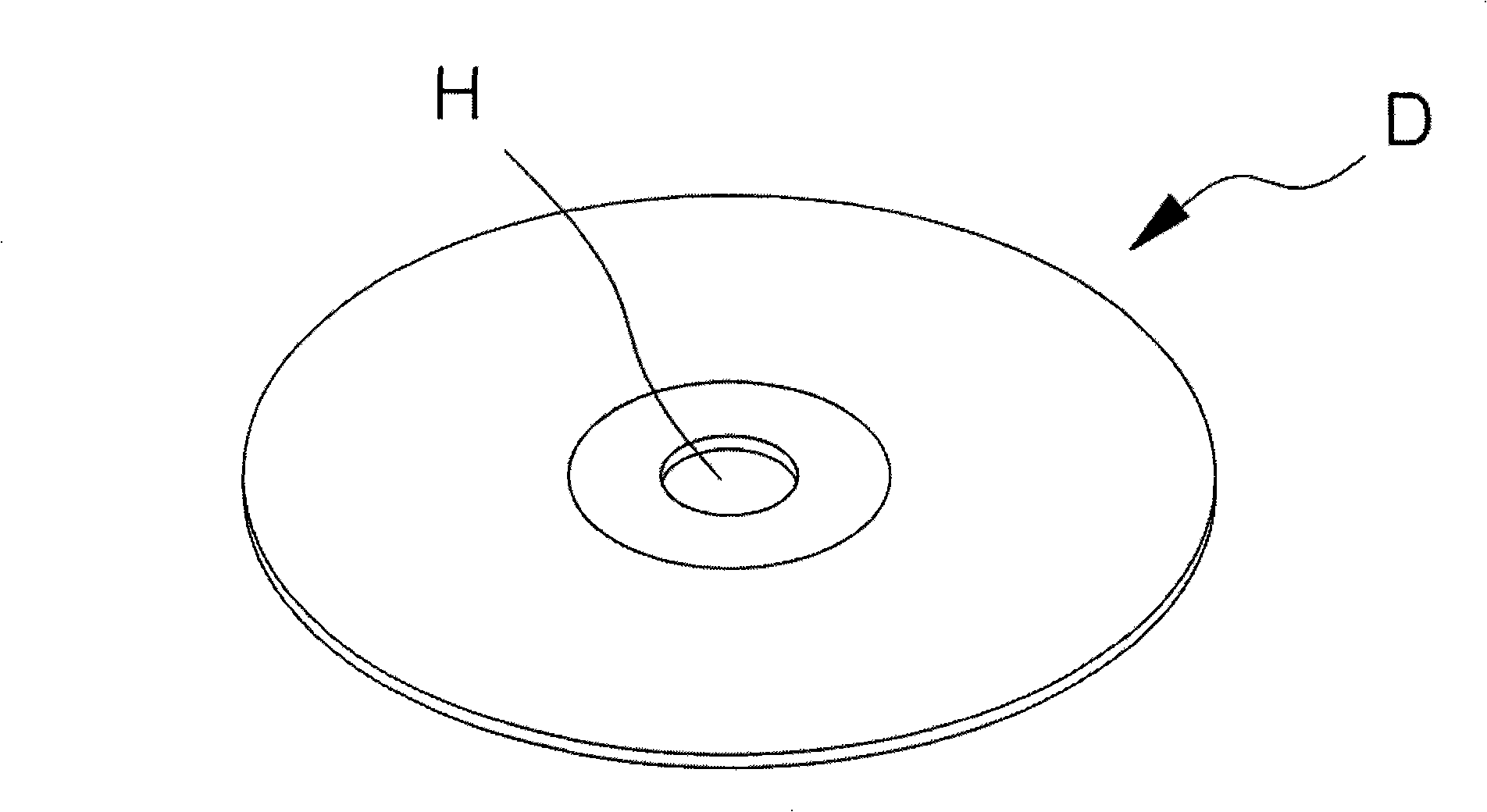

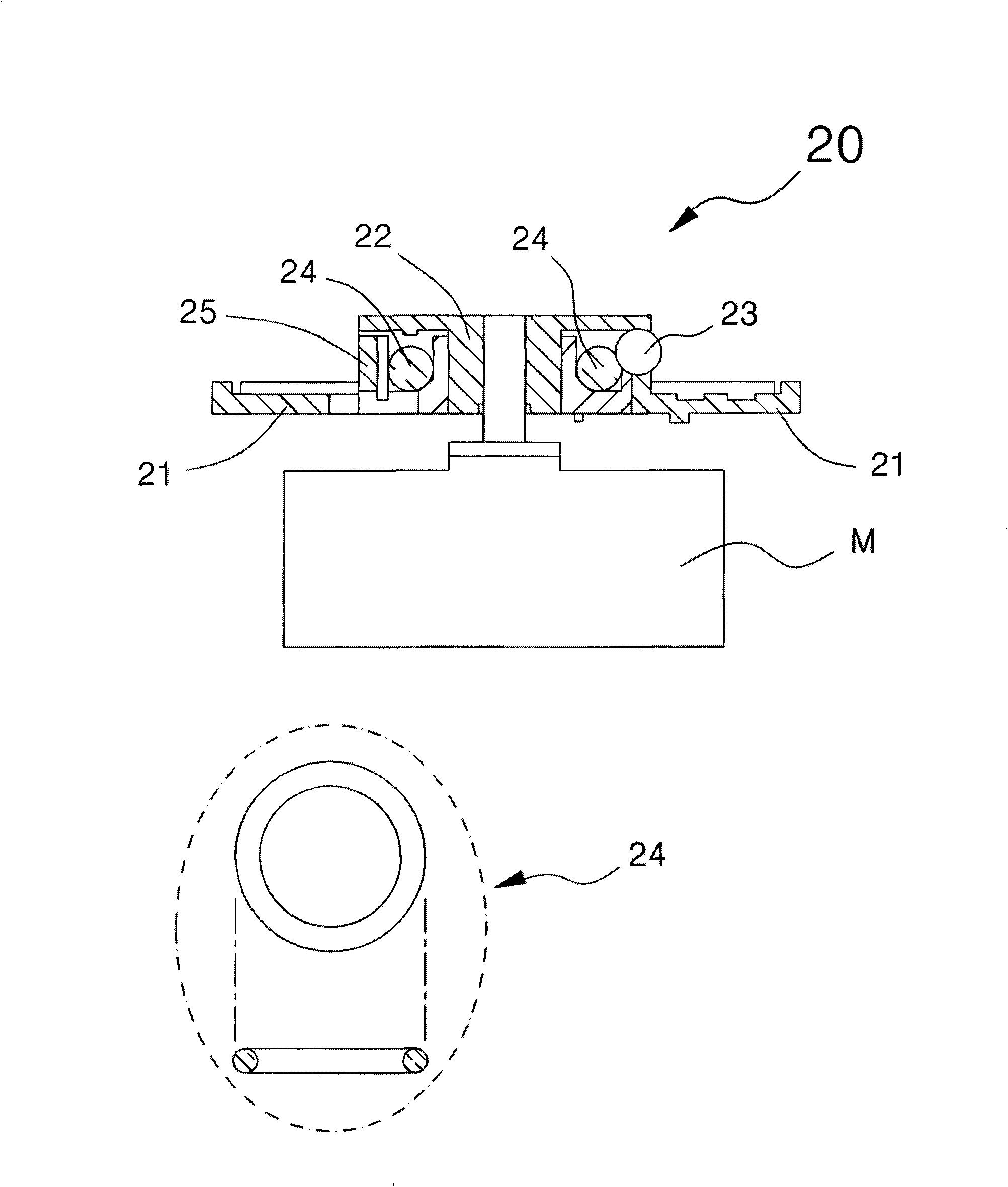

[0063] First of all, according to the preferred embodiment of the present invention, the disc clamping turntable 100 (hereinafter referred to as 'turntable') is as follows Figure 3a , Figure 3a' and Figure 3b As shown, it includes a circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com