Solar panel automatic detection machine

A solar panel and testing machine technology, applied in the direction of single semiconductor device testing, sorting, etc., can solve the problems of limited labor speed, increased production cost, fatigue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

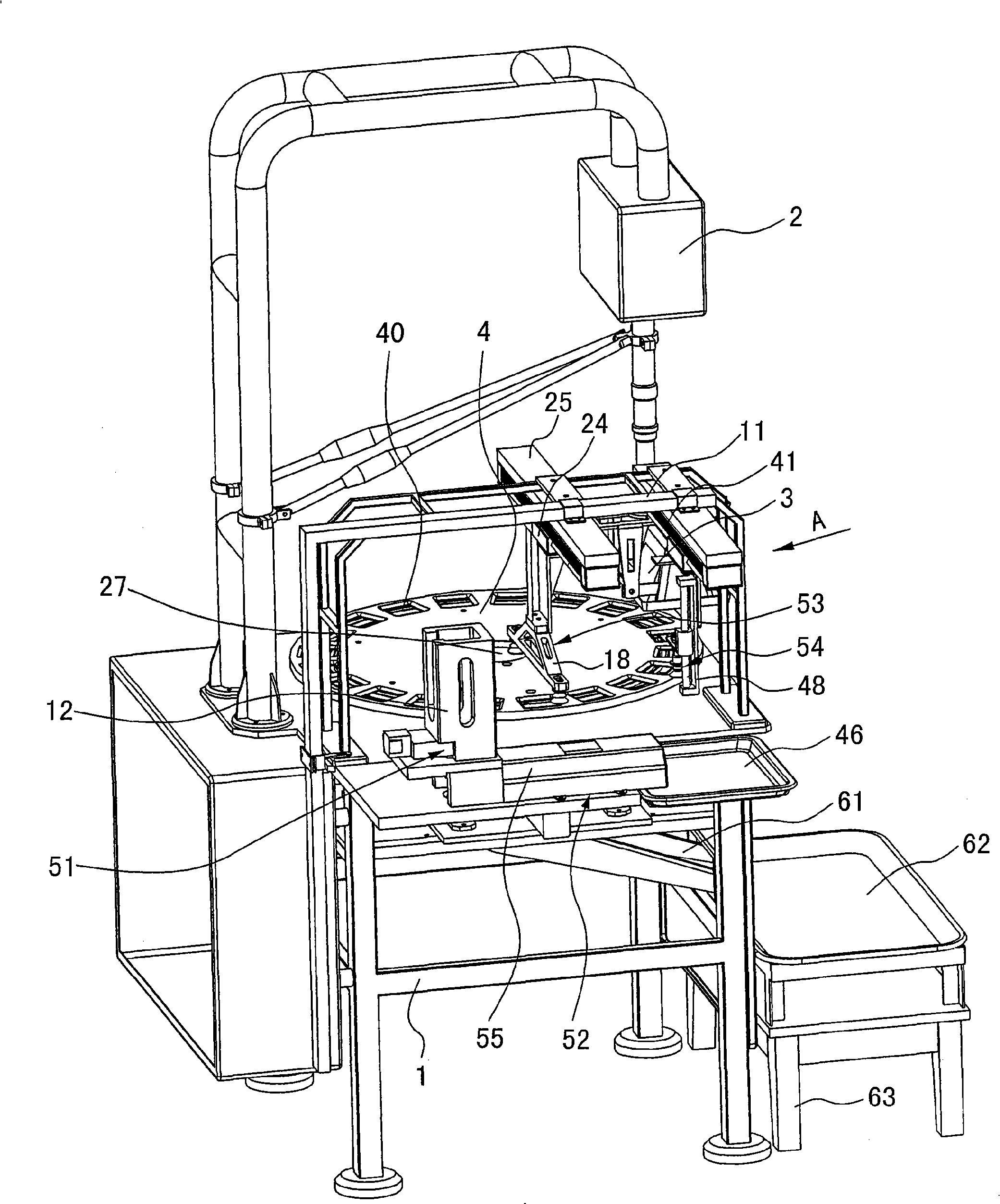

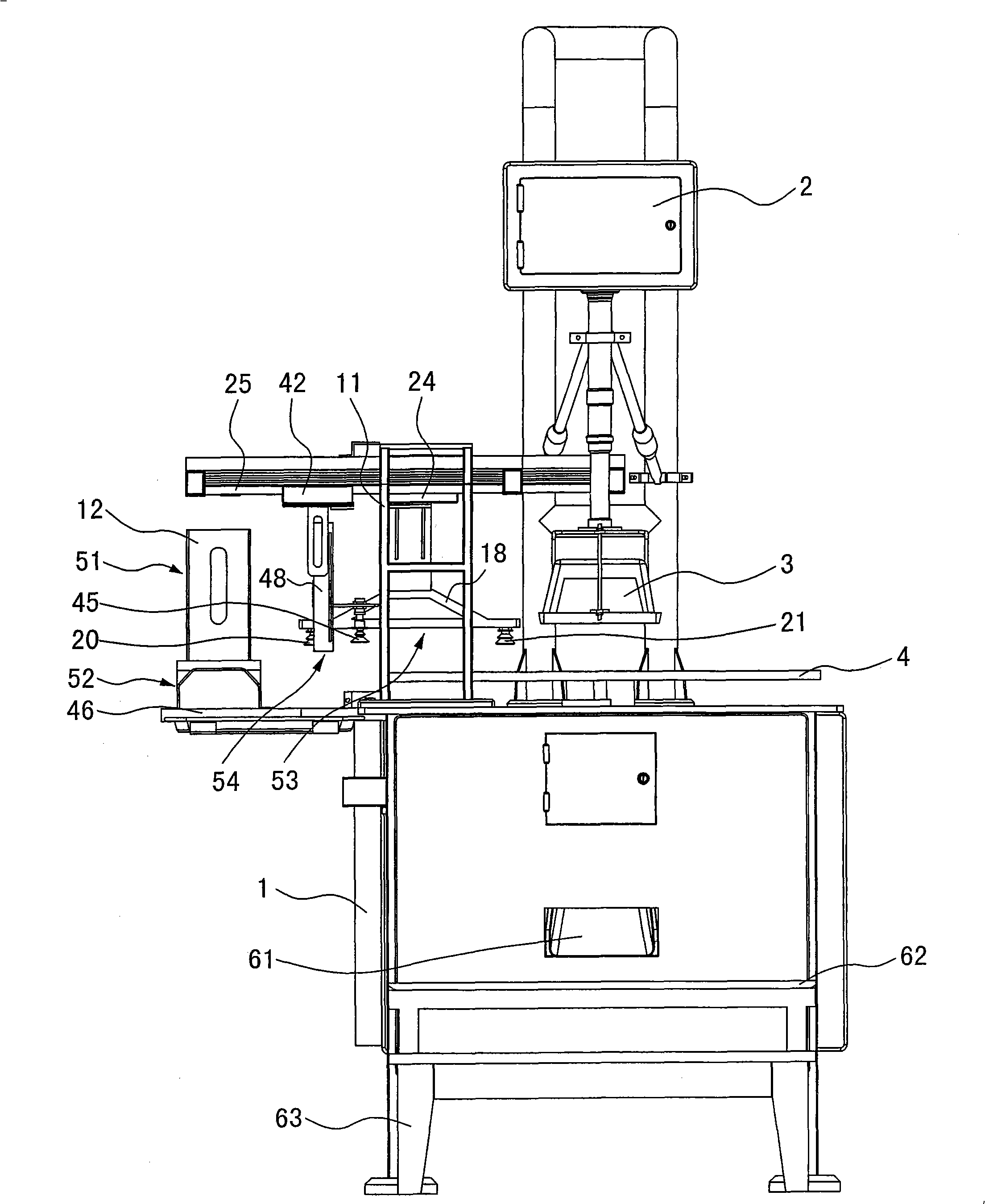

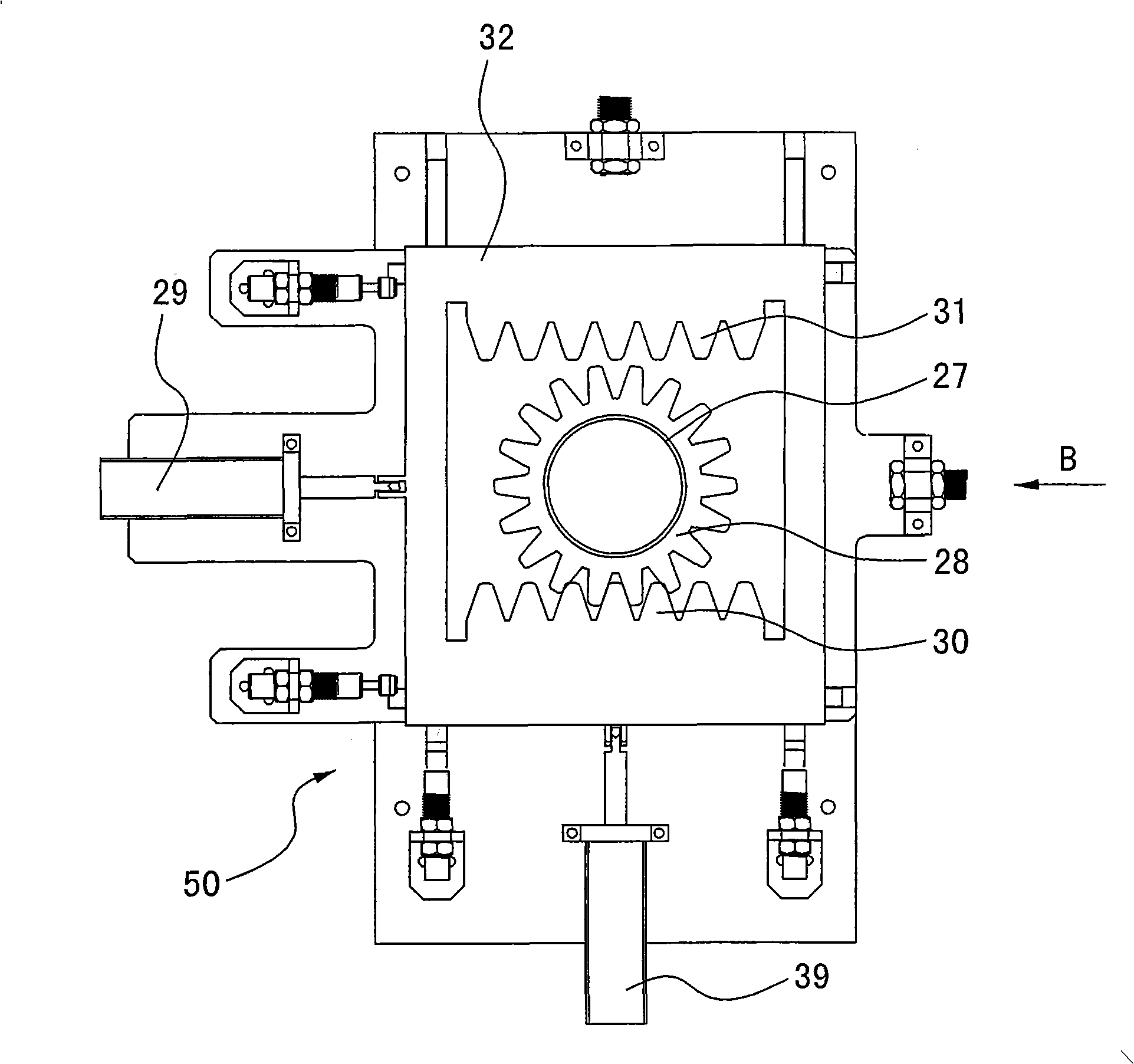

[0015] The present invention relates to automatic detection machines for solar panels, such as Figure 1-Figure 8As shown, it is characterized in that it includes a frame 1, on which a battery board input device, a counting turntable 4 and a rotating device 50, a detection control box 2, a detection lamp 3, a screening device 54 and a delivery storage device are installed. The device includes a battery board insertion mechanism 51, a left and right movement mechanism 52, and a front and rear conveying mechanism 53. The insertion mechanism includes a placement bracket 12, and the bottom of the placement bracket 12 is equipped with a stop piece 13, and the stop piece has a sensor controller. Install the top plate 14 below the support 12, the top plate is connected to the air circuit, the air circuit is the cylinder and the control system, the same below, the top plate 14 is in contact with the battery plate 5; the left and right moving mechanism 52 includes a slide block 16, The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com