Thermal insulation insulating panel of polyphenyl glass fibre cement and making method thereof

A technology of thermal insulation board and polyphenylene glass fiber, which is applied in the direction of thermal insulation, manufacturing tools, hydraulically coagulable material layered products, etc., to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

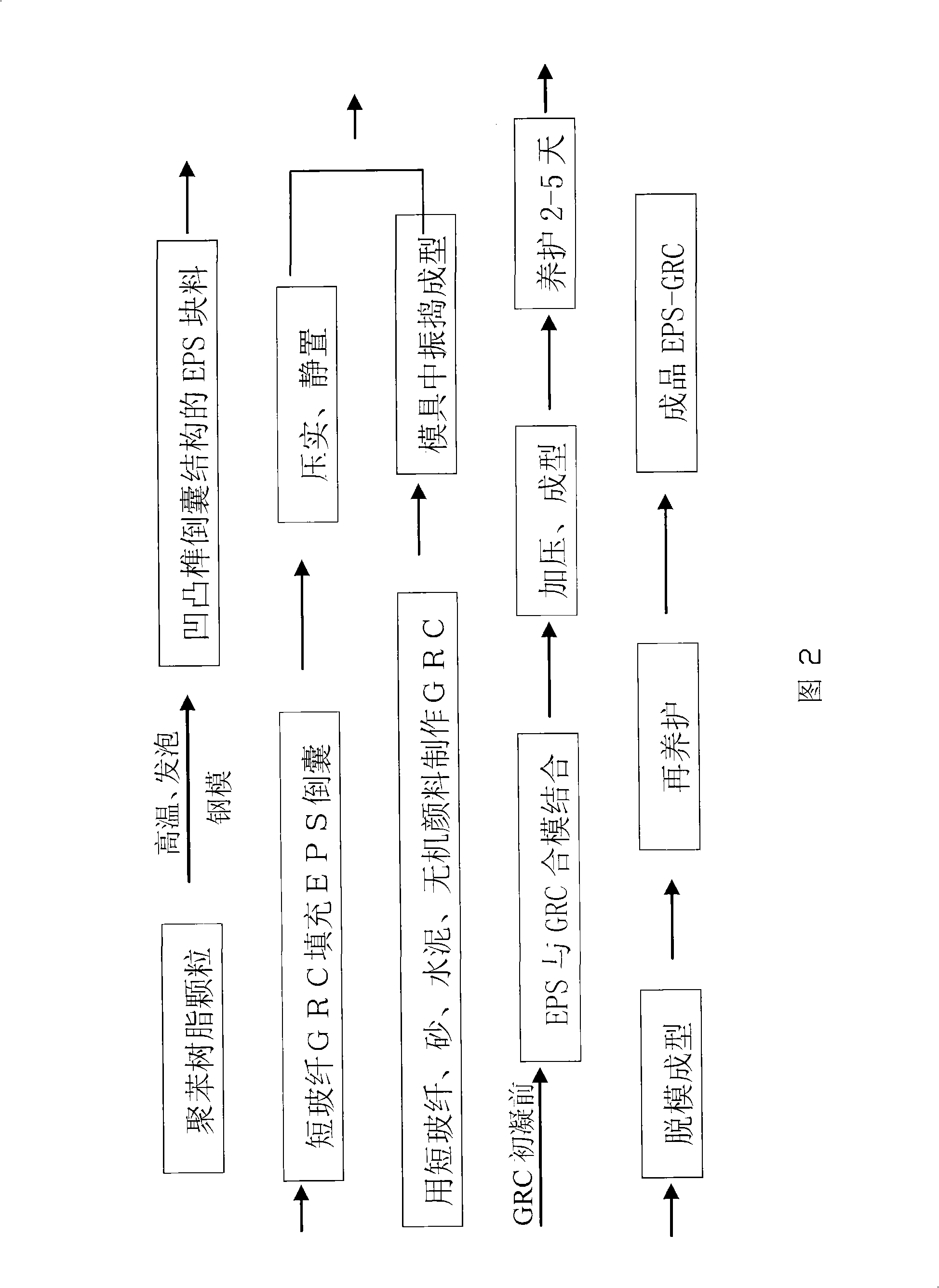

[0029] Polyphenyl fiberglass cement thermal insulation board, such as figure 1 As shown, the lower end of the glass fiber reinforced cement board GRC1 is connected to the polystyrene board EPS2, and the middle end of the polystyrene board EPS2 is provided with a tenon 3 and a tenon 4 .

[0030] Its production process includes,

[0031] (1) Making EPS layer of polystyrene board

[0032] Polystyrene resin particles are used for foaming and molding at high temperature in the steel mold, and the inverted capsule structure and tenon structure corresponding to the EPS layer of the polystyrene board are made in the steel mold;

[0033] (2) Make composite layer

[0034] On the contact surface of the polystyrene board EPS and the glass fiber reinforced cement board GRC, an inverted capsule structure is made. The capsule has a large belly and a small mouth. Fill the premixed short glass fiber reinforced cement board GRC into the capsule and vibrate. , compacted, put it aside for curi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com