Bearing construction of motor

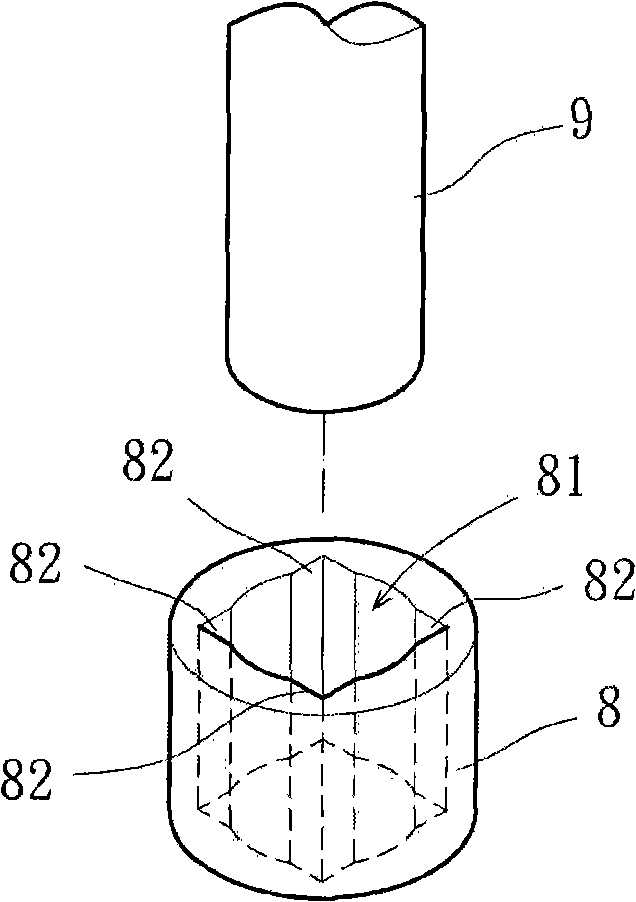

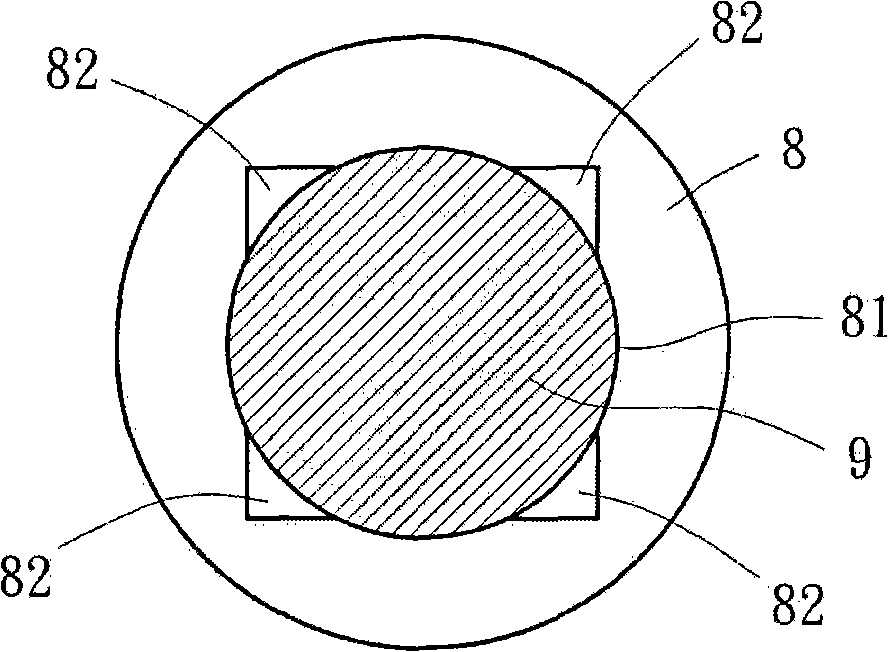

A bearing and structure technology, applied in the field of bearing structure, can solve the problems of increasing the frictional resistance between the oil bearing 8 and the shaft 9, easy loss of lubricating oil, shortening the service life of the motor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

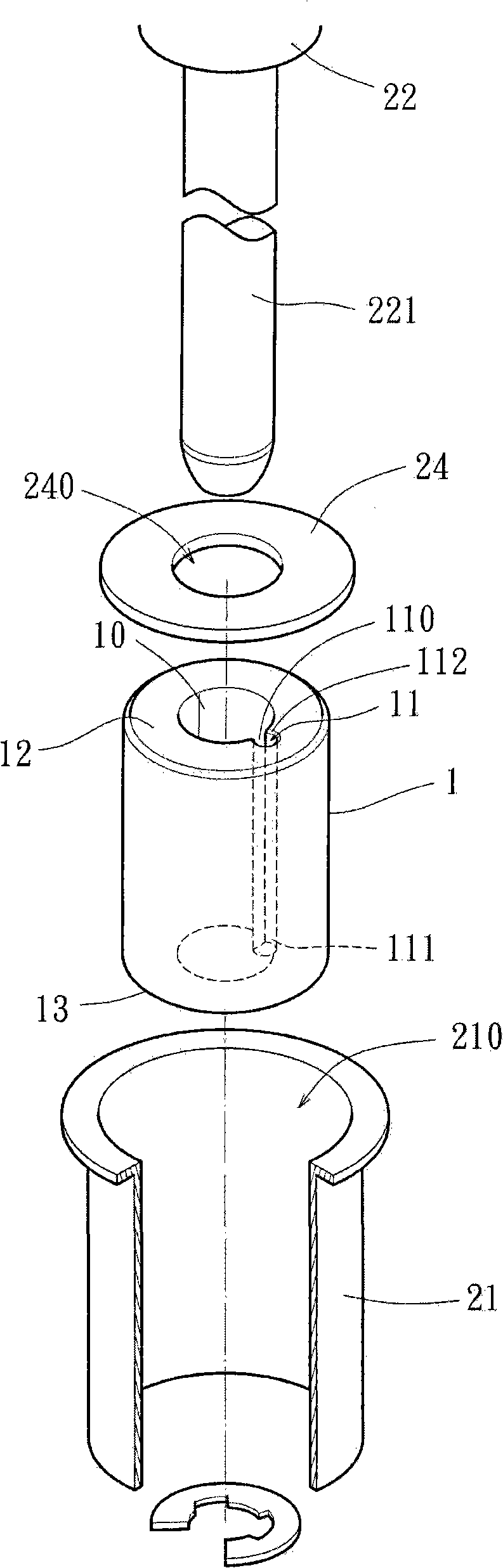

[0035] In order to make the above and other purposes, features and advantages of the present invention more obvious and understandable, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

[0036] Please refer to image 3 , 4 As shown, the bearing structure 1 of the motor disclosed in the first embodiment of the present invention is preferably selected from an oil-impregnated bearing or a hydrodynamic bearing. The bearing 1 mentioned in the example is correspondingly assembled in a shaft tube 21 of the motor 2 and can be passed through by a rotor 22 of the motor 2 . A stator 23 is provided on the outer peripheral surface of the shaft tube 21 .

[0037] please refer again image 3 , 4 As shown, the bearing 1 described in the first embodiment of the present invention includes a shaft hole 10 and at least one guide groove 11, and the bearing 1 has two end faces, which are respectively a first end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com