Mounting duct for sodium-cooled fast reactor inner sodium liquid level meter

A technology for installing channels and sodium-cooled fast reactors, which is applied in fast fission reactors, reactors, nuclear reactors, etc. good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

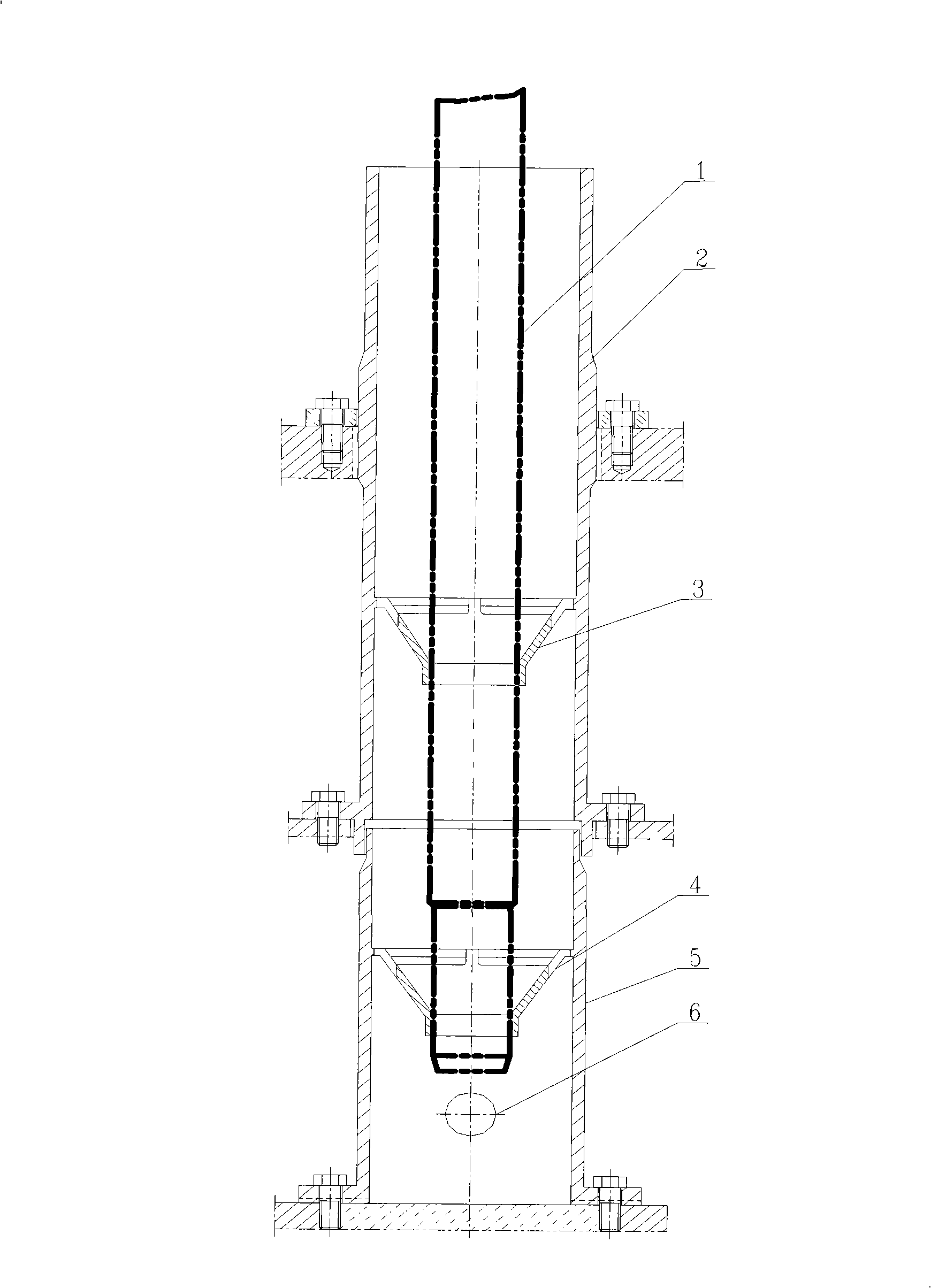

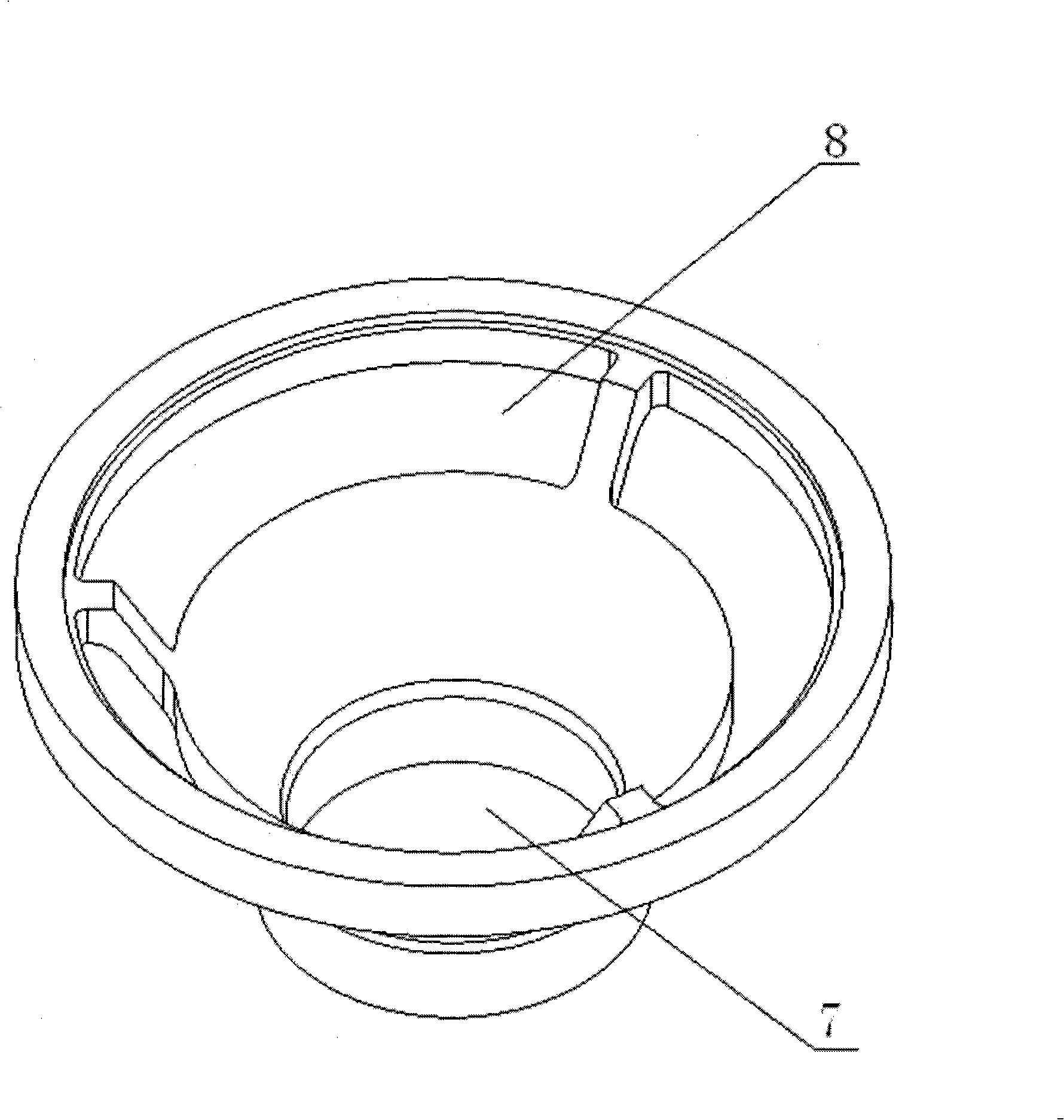

[0011] The installation channel of the sodium level gauge in the sodium-cooled fast reactor can be composed of one or more pipes of different lengths welded together, and the limiting parts inside the pipe can also use one or more to adjust the sodium level gauge 1 as required. position. In order to make pipeline processing and installation more convenient, such as figure 1 The present embodiment shown is composed of a circular upper pipe 2 and a lower pipe 5, wherein the upper pipe 2 and the lower pipe 5 are respectively connected with a conical piece 3, 4 as a limiting part of the sodium level gauge 1, and the upper The lower end and upper part of the pipeline 2, and the lower end of the lower pipeline 5 respectively use flanges to securely install the whole pipeline on the inner support and the inner shield of the pile. Have 2 holes 6 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com