TFT-LCD panel test system and its test method

A panel testing and panel technology, applied in the field of TFT-LCD, can solve the problems of complex design, high cost, and inability to detect LCD panels, and achieve the effect of reducing additional costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

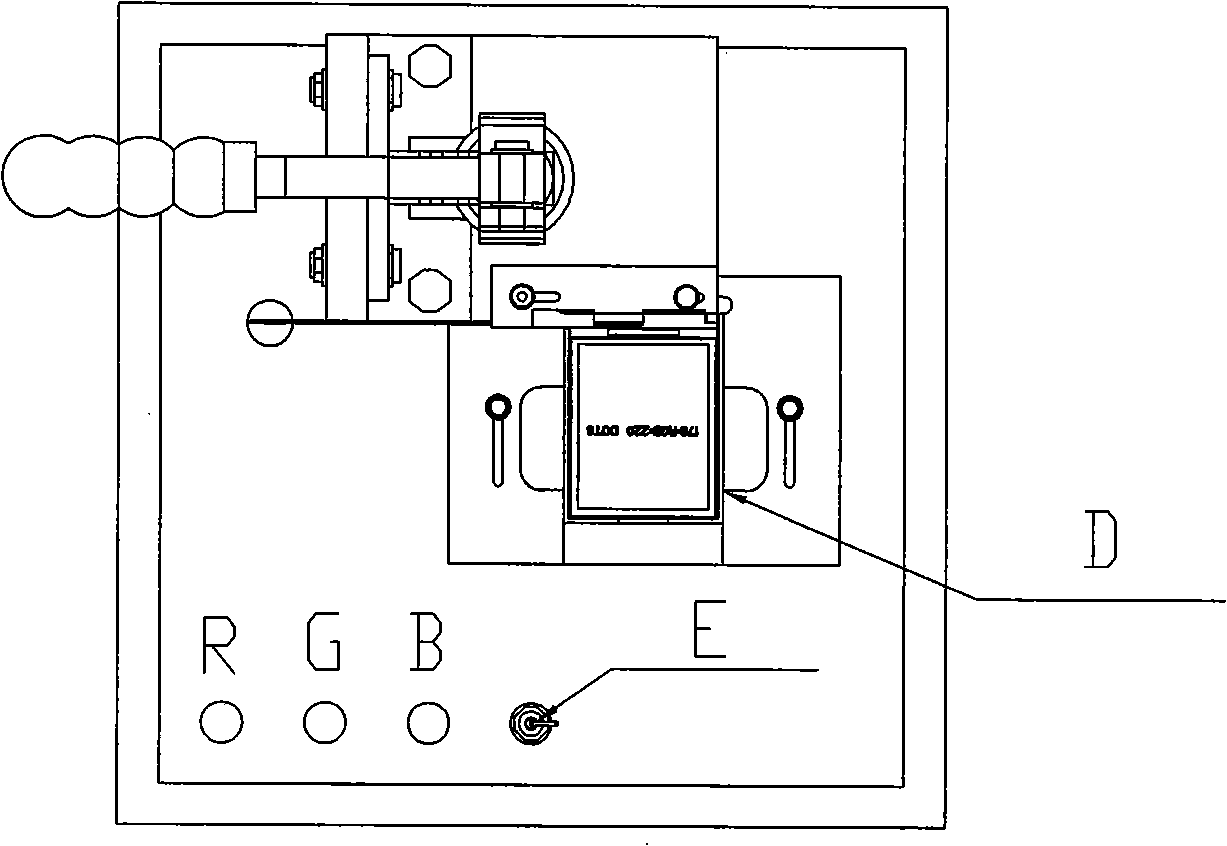

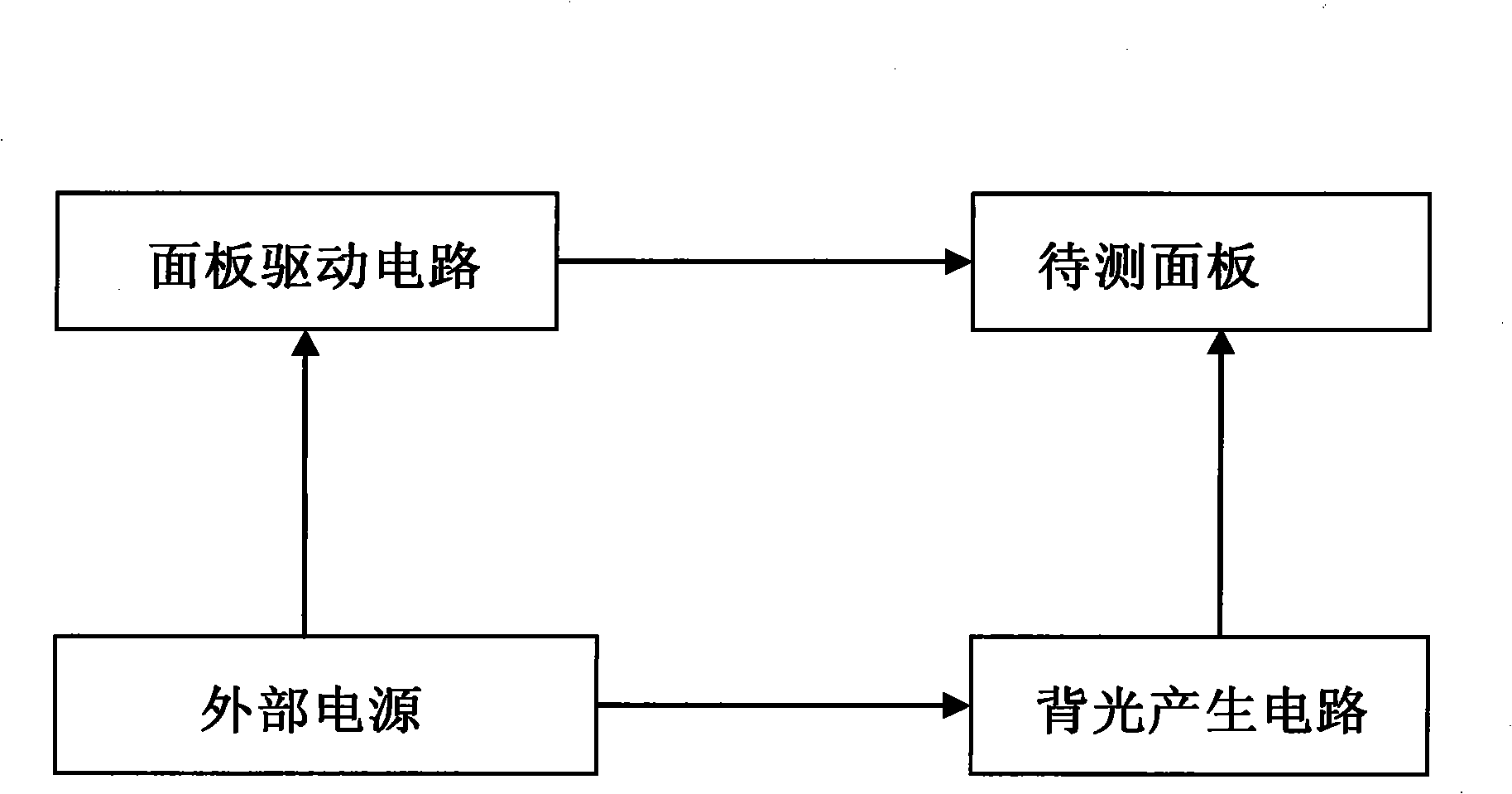

[0014] see figure 1 , figure 2 As shown, a TFT-LCD panel testing system of the present invention includes a mechanical structure part and a circuit structure part. The mechanical mechanism part includes handle A, sliding plate B, probe C, panel placement groove D and power switch E. In addition, R, G, B buttons are also arranged on the base of the mechanical mechanism. The panel to be tested is placed on the placement groove D, the sliding plate B is used to fix the probe C, and the handle A is used to crimp the probe C and the test point on the panel; wherein, the sliding plate B and the panel are placed Slot D can be replaced according to different types of panels. When applying, first place the panel to be tested in the panel placement groove D, adjust the position of the sliding plate B and the panel placement groove D, press the handle A, so that the probe C just presses on the test point of the panel to be tested; then Fix the sliding plate B and the housing groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com