Power tool

A power tool and power source technology, applied in the direction of manufacturing tools, manual planers, portable mobile devices, etc., can solve the problems that debris cannot be completely discharged, electric planing is easy to block chips, and chip removal efficiency is low, so as to achieve thorough chip removal , It is not easy to block chips, and the effect of high chip removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

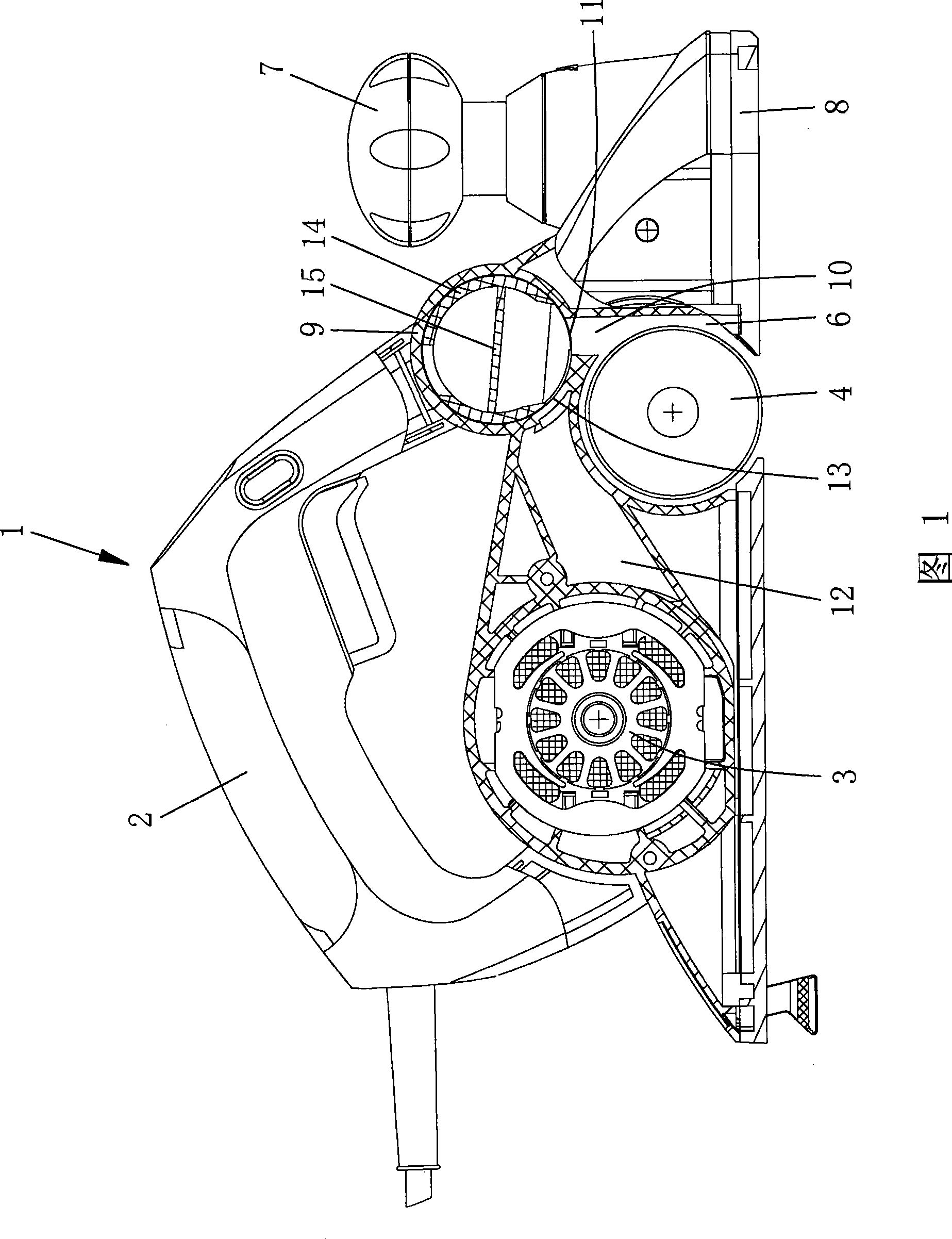

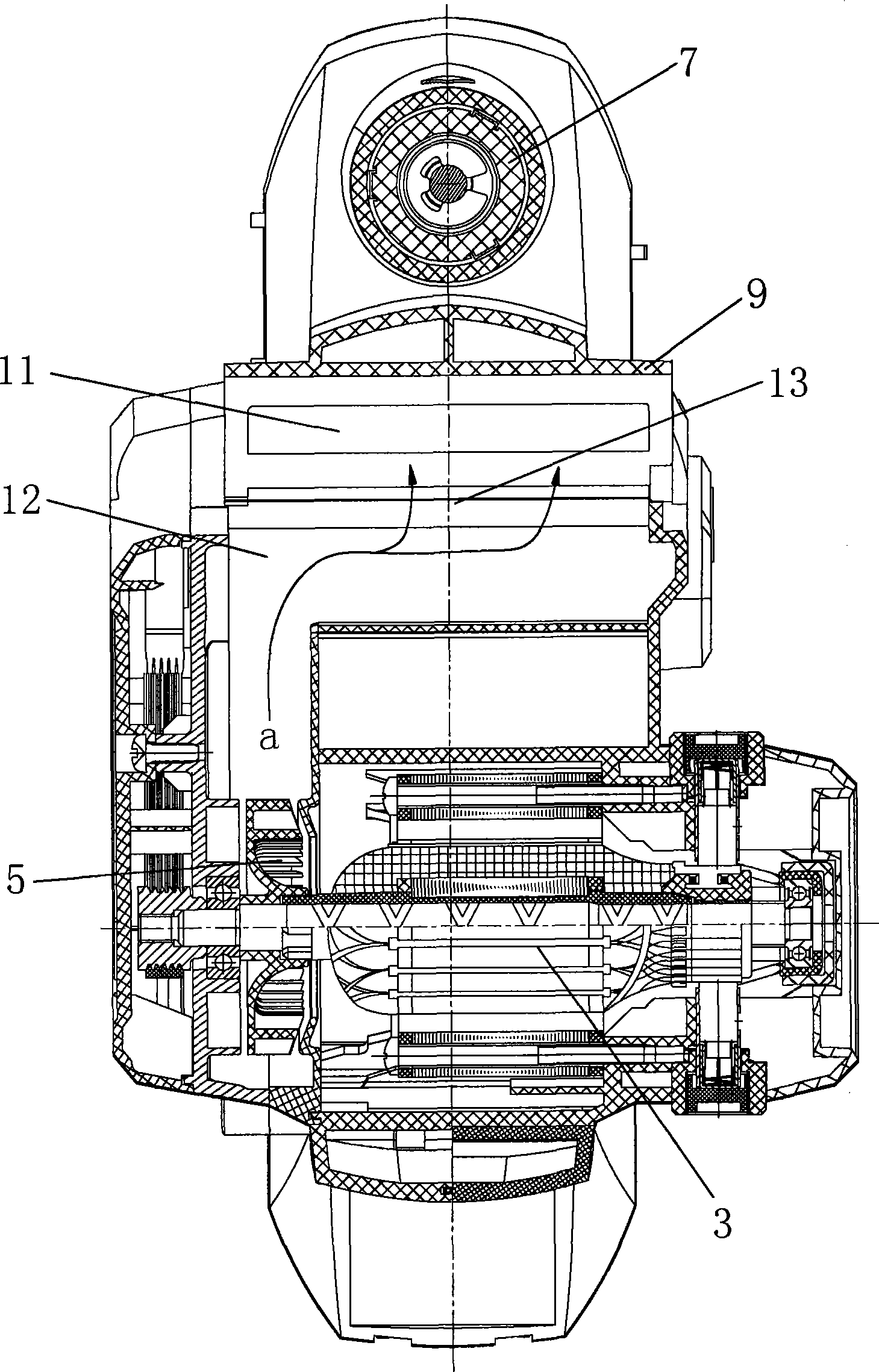

[0032] See Figure 1, figure 2 As shown, a hand-held electric planer has a housing 1, a main handle 2 fixedly connected to the housing 1, a power source 3 accommodated in the housing 1, and a fan 5 connected to the power source 3. The planer 4 driven by the power source 3 is arranged in parallel with the power source 3 .

[0033] The casing 1 has a cylindrical first receiving chamber 6 extending transversely, and the planer 4 is disposed in the first receiving chamber 6 . An adjustable sub-handle 7 is provided near the front of the housing 1, and the sub-handle 7 is used to adjust the height of the bottom plate 8 so as to adjust the cutting depth of the electric planer.

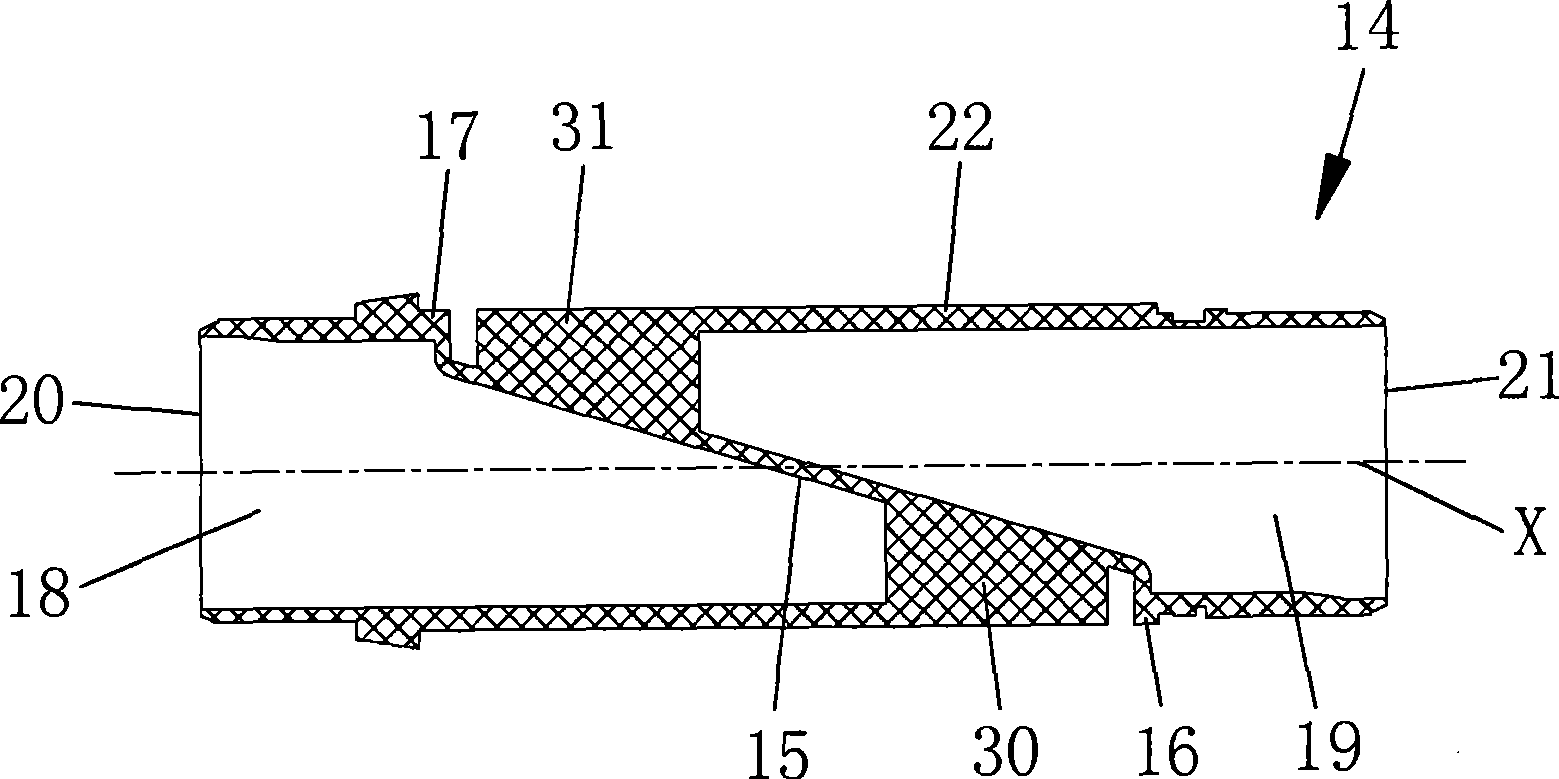

[0034] The casing 1 is located above the first receiving chamber 6 and is provided with a laterally extending tubular second receiving chamber 9 . A chip discharge duct 10 is connected between the first storage cavity 6 and the second storage cavity 9 , and the chip discharge channel 10 has a chip discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com