Screw cap

A screw cap and cover plate technology, applied in the directions of capping, bottle/container caps, and capping containers tightly with caps, which can solve problems such as rainwater accumulation and dirt deposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

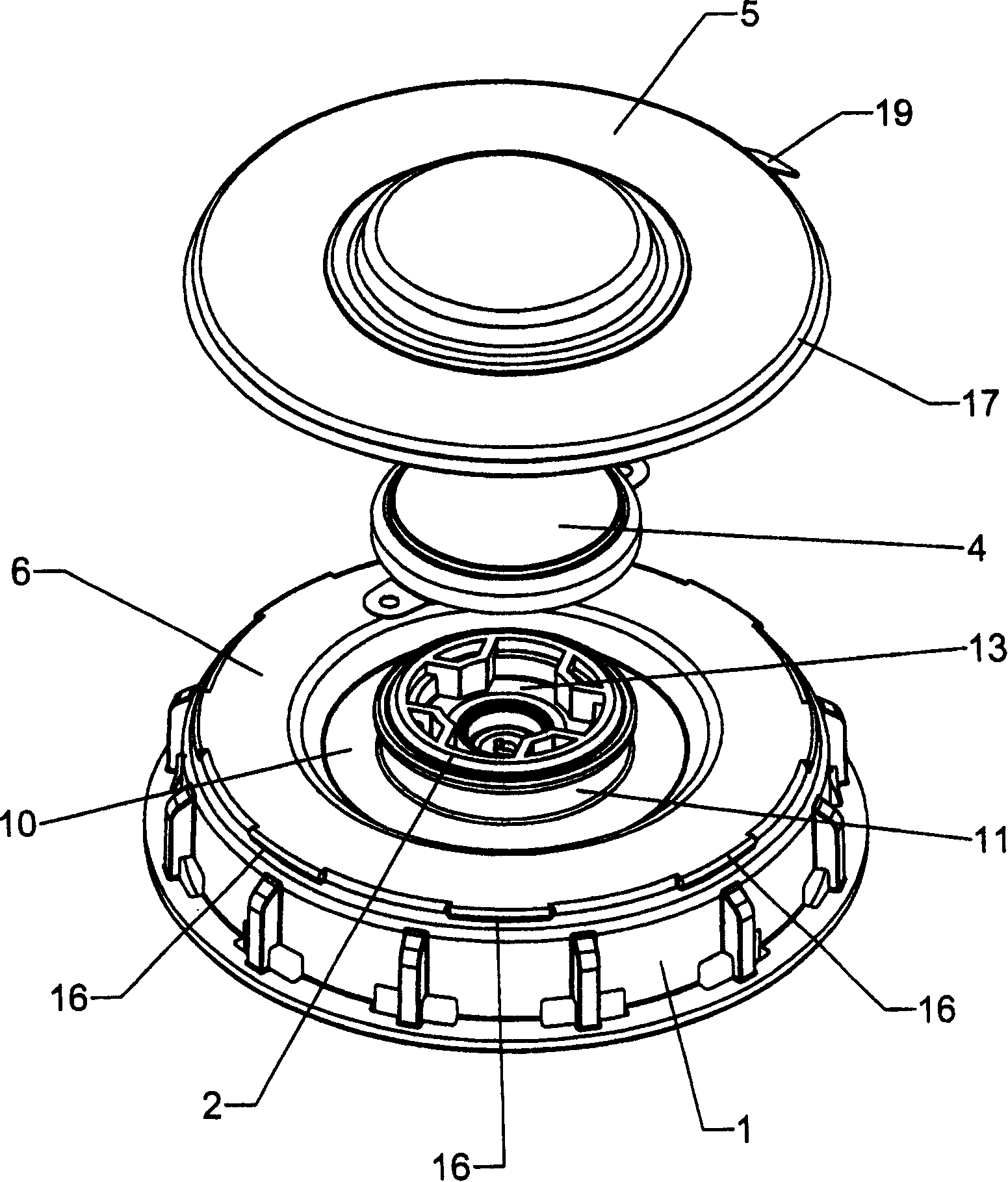

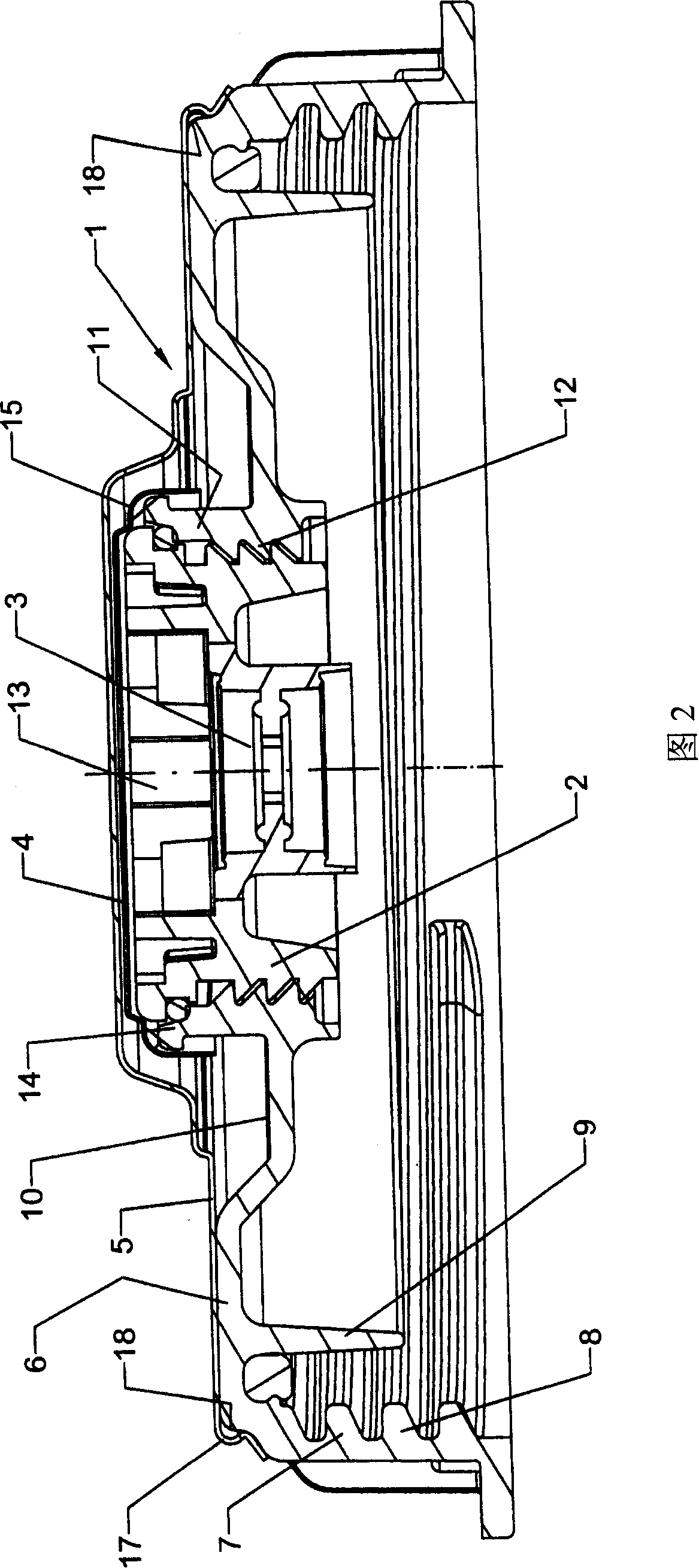

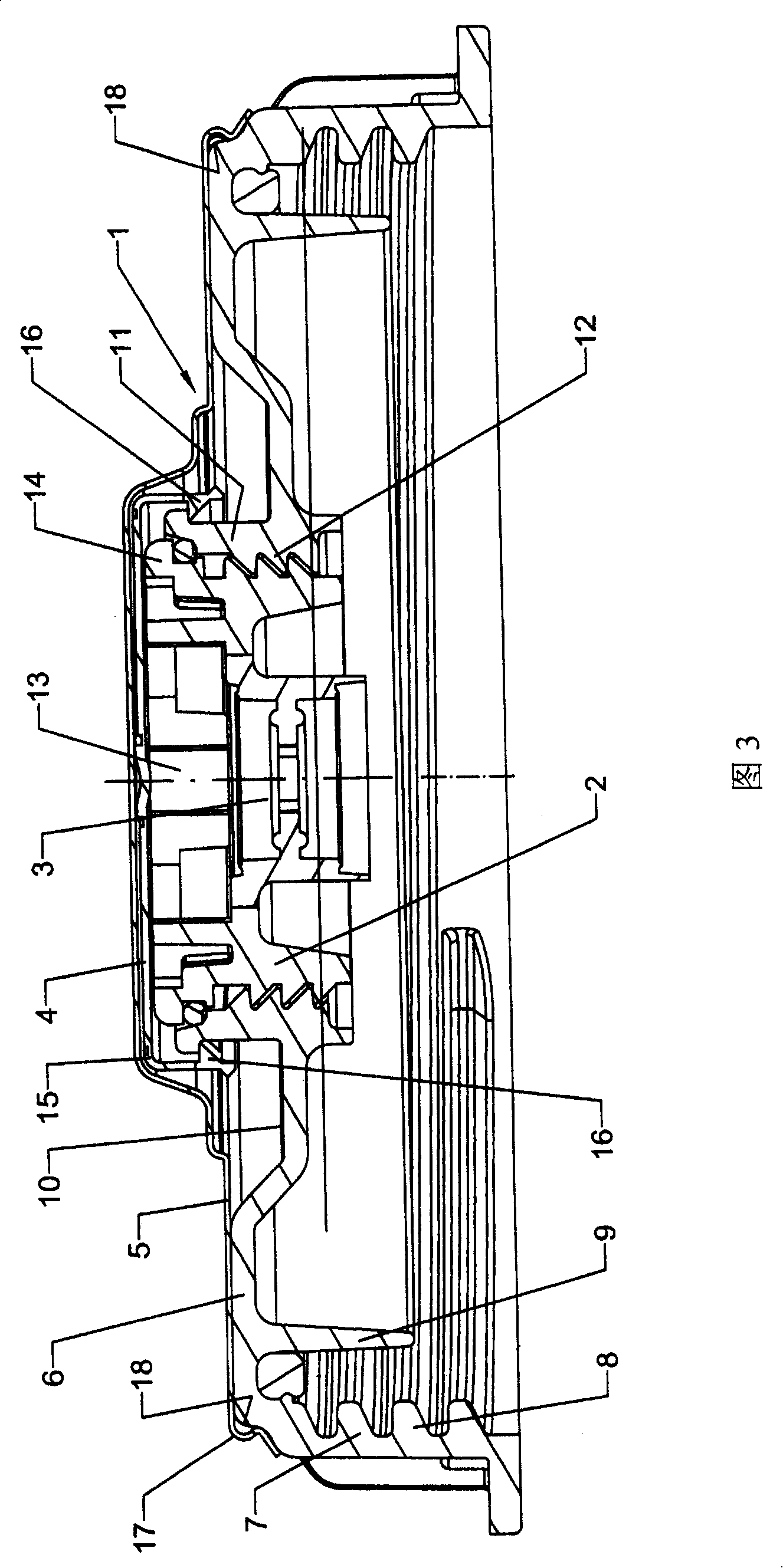

[0011] The plastic screw cap 1 is equipped with a bung 2 integrally integrated with a venting-and-inflating device, a sealing cap 4 and a protective cap 5 completely covering the screw cap 1 .

[0012] The screw cap 1 comprises a flat cover plate 6, which is vertically attached to an outer cover edge 7 and an inner cover edge 9 at the circumference of the cover plate, wherein the outer cover edge has an internal thread 8 to close the filling nozzle of the liquid storage and transportation container and / or The extraction nozzle, while the inner lid edge 9 is arranged in the center of the outer lid edge 7 and serves to reinforce and improve the placement of the screw cap on the filling and / or removal nozzle of the container.

[0013] In the central basin-shaped recess 10 of the cover plate 6 of the screw cap 1, a bung connecting pipe 11 is sunk. Insufficient pressure in the vent and inflator bung 2. The bung 2 has an upper engagement opening 13 adapted to a bung key for screwin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com