Welding torch and end piece and also contact tube for a welding torch

A technology of tail end piece and conductive tube, applied in the field of welding torch, can solve the problems such as can not be compensated, reduce the service life of the conductive tube, and the welding wire wears a lot, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] First of all, it is pointed out that the same reference numerals refer to the same components in the exemplary embodiments.

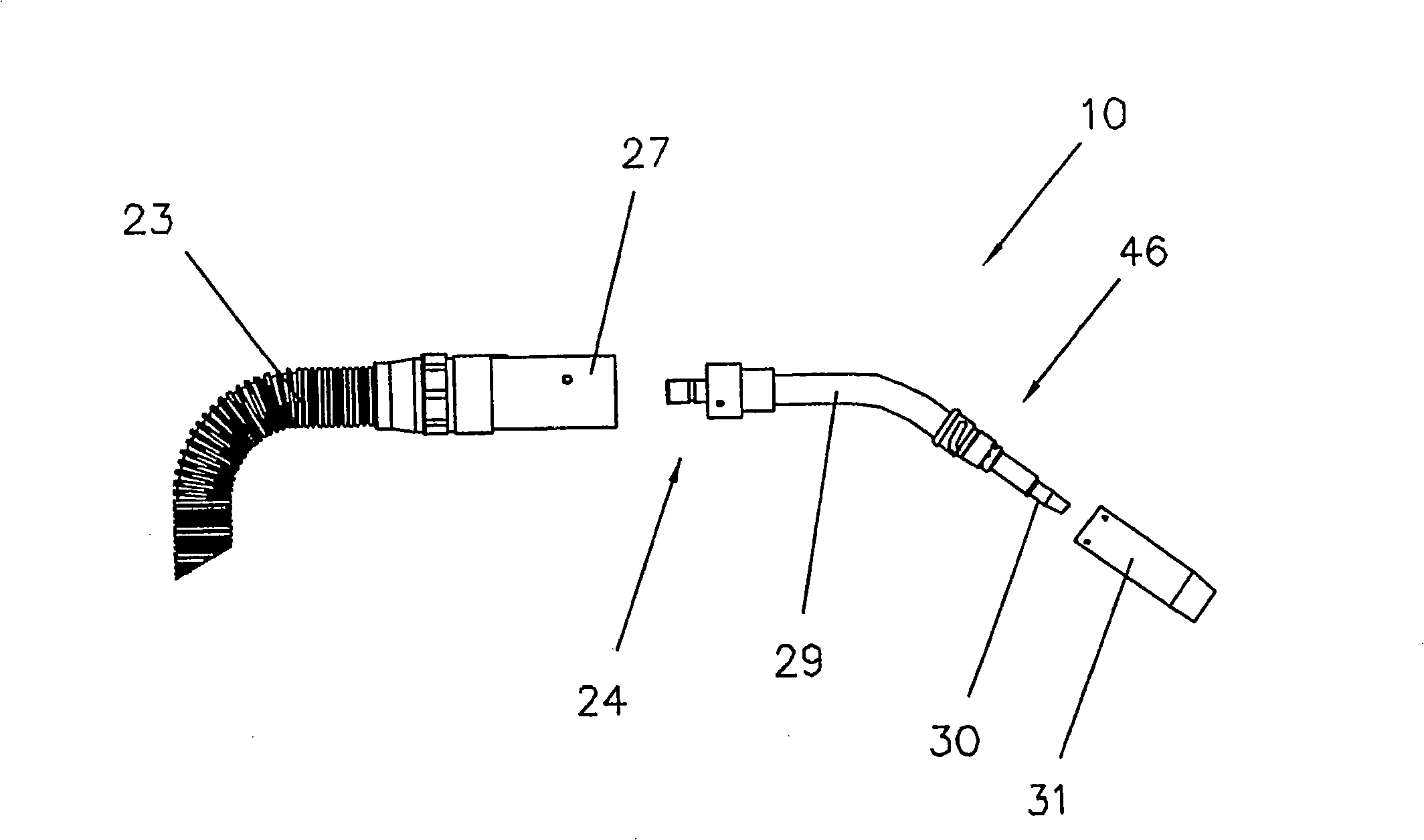

[0050]Figure 1 shows a welding device 1 or welding equipment for various welding processes or methods, such as MIG / MAG welding, or WIG / TIG welding, or arc welding methods, twin wire / front and rear wire welding method, plasma welding or brazing, etc.

[0051] The welding device 1 includes a power source 2 including a power element 3 , a control device 4 and a switching member 5 associated with the power element 3 and the control device 4 . The switching element 5 and the control device 4 are connected to a control valve 6 arranged in a supply line 7 for a gas 8, in particular a shielding gas such as carbon dioxide, between the gas container 9 and the welding torch 10 or welding torch , helium, argon, etc.

[0052] In addition to this, the wire feeder 11 normally used for MIG / MAG welding can also be activated by the control device 4, and addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com