Novel double oscillation tumbling barrel scouring machine

A washing machine and double-oscillation technology, which is applied to dry-cleaning fiber products, textile processing machine accessories, and processing textile material drums, etc., can solve the problems of poor quality, large consumption, and poor washing effect of fabrics, and achieve good quality and shrinkage. Large, good washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

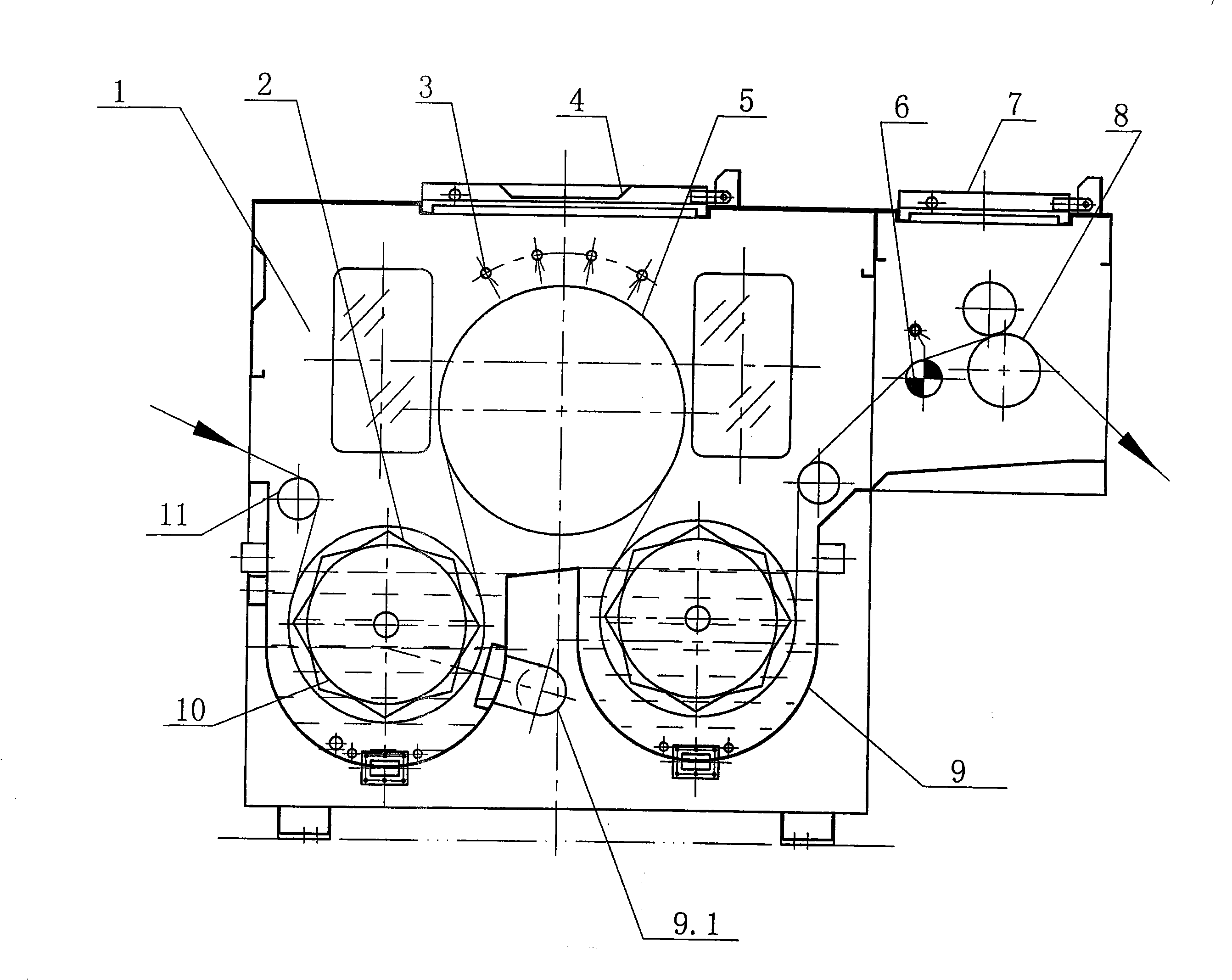

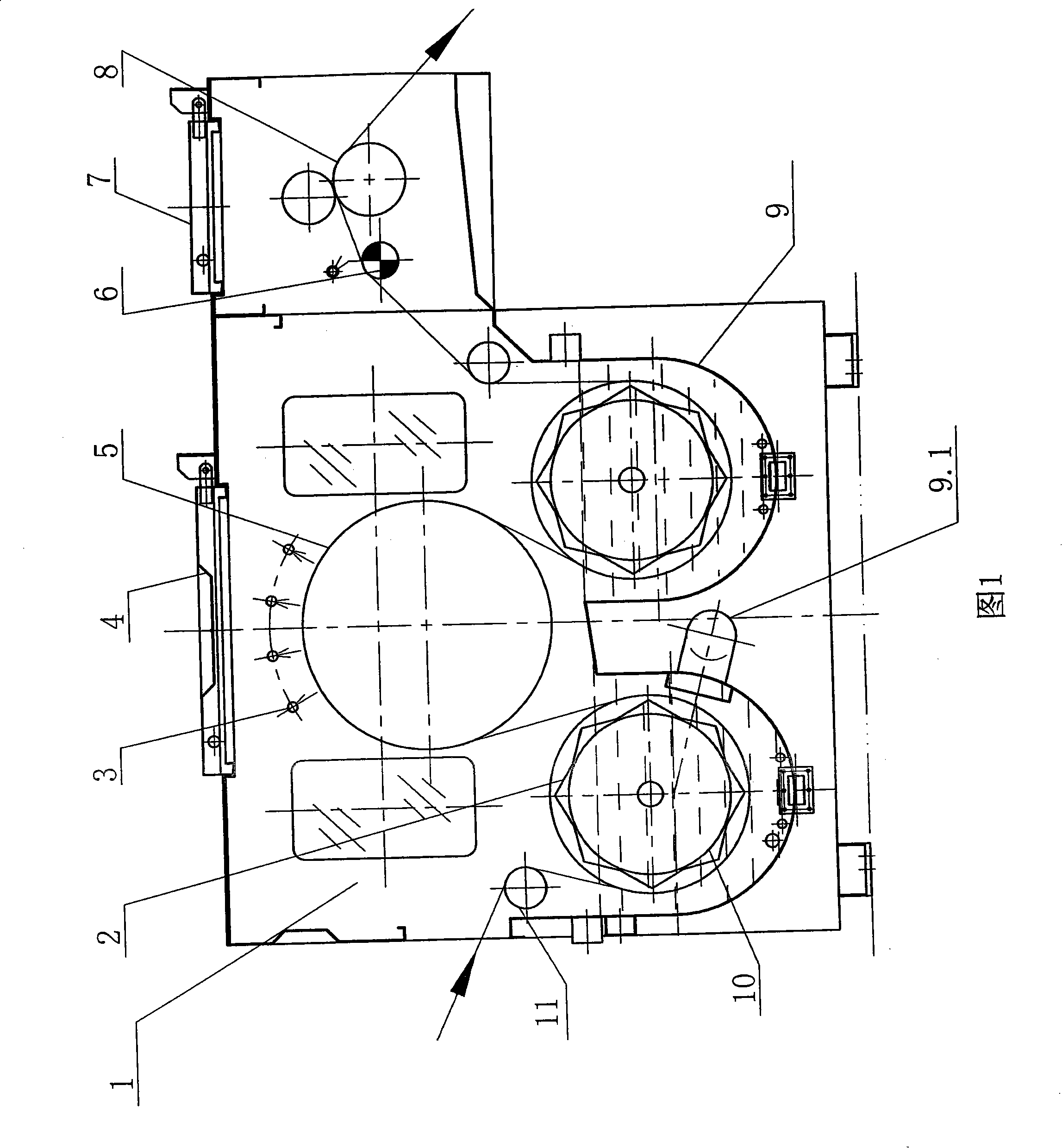

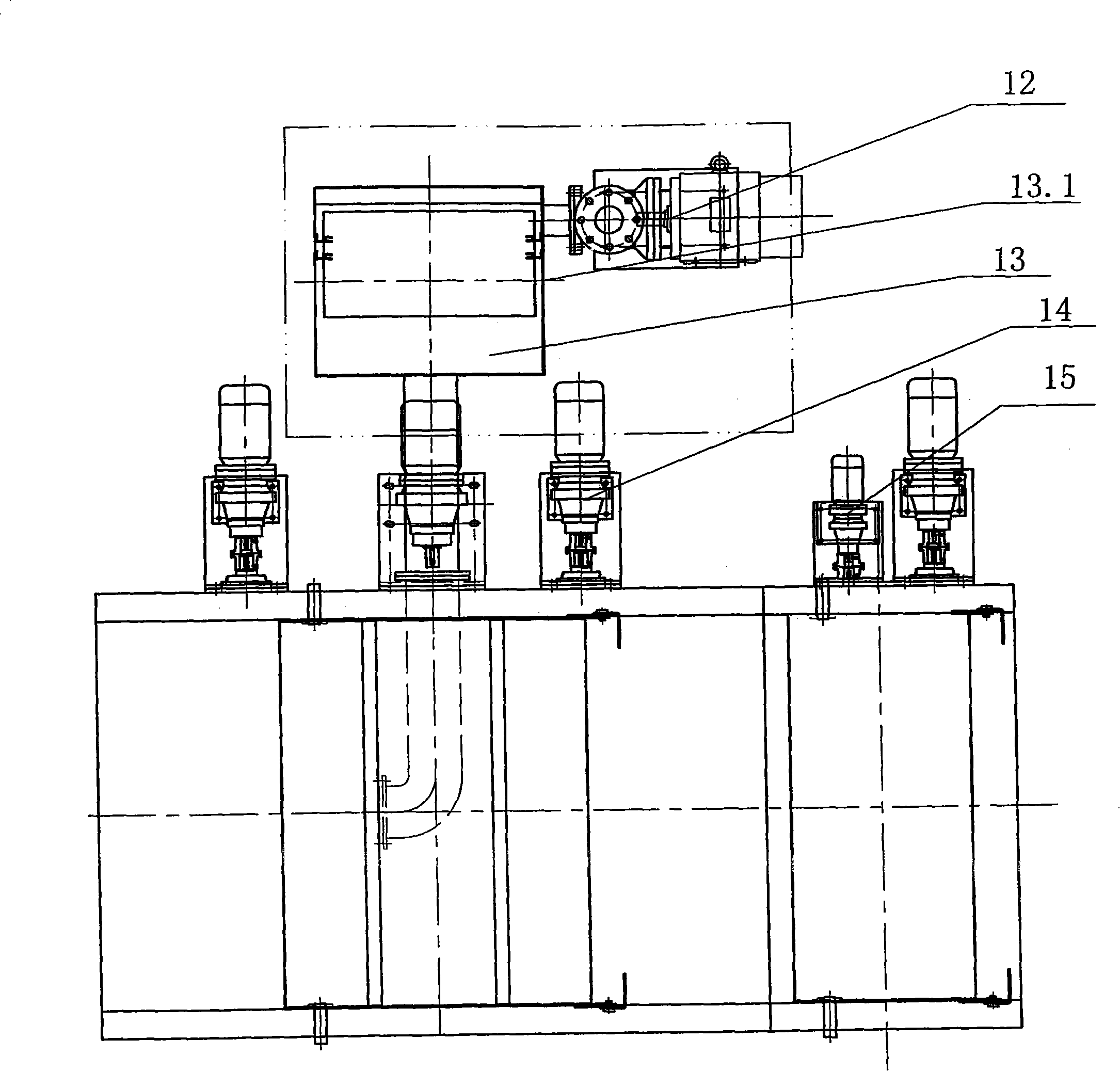

[0019] Referring to Figures 1 to 3, the novel double-oscillating drum water washing machine involved in the present invention includes a box body 1, and a water tank 9 is longitudinally arranged in the lower part of the box body 1, and there are two water tanks 9, one on the left and one on the left. Each device in the two water tanks 9 has an outer mesh roller 2, wherein a cloth guide roller 11 is arranged on the upper left of the outer mesh roller 2 on the left; each device in the two outer mesh rollers 2 has a plum blossom roller 10; A net-shaped drum 5 and a spray device 3 are arranged in the middle of the upper part of the box 1, and the spray device 3 is placed above the drum 5; The splitting roller 6 and the two-roll padding car 8, the two-rolling padding car 8 is placed on the right side of the active splitting roller 6; the top of the box body 1 is provided with a box cover I4 and a box cover II7, which are sealed with a water seal structure.

[0020] Described box bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com